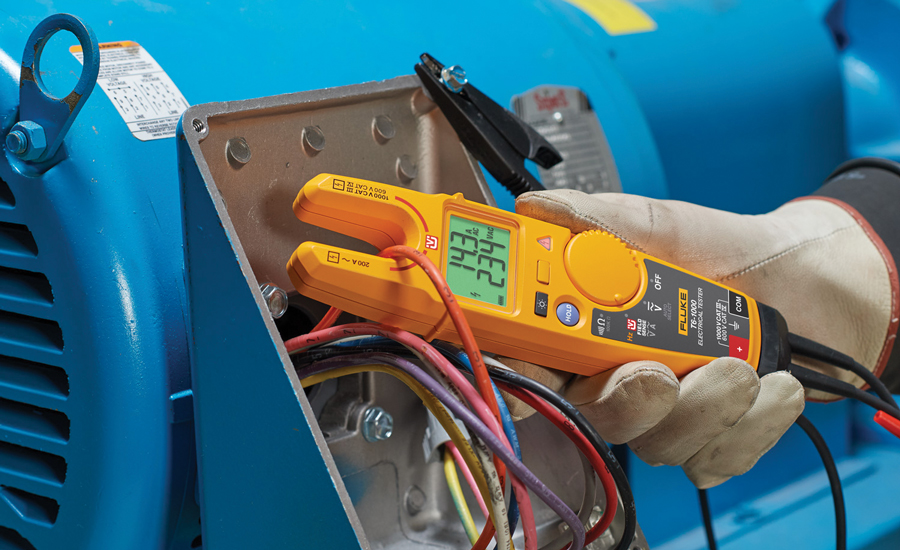

Taking home the golden honors in the Testing and Monitoring category of this year’s Dealer Design Awards is the T6 Electrical Tester from Fluke Corp. The product, first introduced to the marketplace in September 2017, went through years of research before launching.

“The T6 Electrical Testers with FieldSense technology are the culmination of years of research, not only into the technology but also on the user experience,” said Brian Painting, electrical testers product manager, Fluke. “At Fluke we’re always in continuous improvement mode — we are committed to understanding the evolving needs of our customers and developing the technology to meet those needs. In that sense, you could say we’ve been researching the T6 ever since we launched the T5.”

“Fluke constantly works closely with customers during the development process, and the T6 was no exception,” said Painter. “We partnered with many electricians and technicians, giving them prototypes and collecting their feedback as we progressed. The continuous input directly from customers really helped us to tailor the T6 to their needs.”

Painter highlighted how the need for a safer, faster, and less intrusive means of measuring both current and voltage — without metallic contact — was clearly identified. Concurrently, Fluke engineers were developing the technology to measure voltage levels without making metallic contact to a live conductor. The intersection of these two projects resulted in the T6 Electrical Tester.

Fluke has been a consistent presence in the Dealer Design Awards, winning multiple awards in recent years, and as with previous winning products, the T6 was driven largely by contractor and customer feedback.

According to Dan Wright, marketing manager, Fluke Corp., what sets the T6 apart from the competition is its FieldSense technology. This technology is what allows electrical measurements without making contact with the aforementioned metallic contact points. This is important because of the safety it allows.

“Without requiring metallic contact, electricians can do their jobs much safer with reduced risk of spark or arc flash while making voltage measurements,” said Painting. “This combined with the other attributes that customers have come to expect from Fluke, such as ruggedness, reliability, and accuracy, make the T6 the go-to tool for front line troubleshooting.”

Mark Horner, lead electrician, facilities engineering, Fred Hutchinson Cancer Research Center, Seattle, agreed.

“The T600 is a good choice for me because it is manufactured by a reliable well-established company that makes quality products that are dependable,” he said. “The most notable feature that makes this product stand out is definitely the wireless voltage reader. The simplicity of this product is another one of its best points. There are no unnecessary features that are uncommonly or never used while doing normal installations or troubleshooting of electrical power distribution.”

Painter added that there are plans to continue the innovation process with the T6, and that it will not be a stagnant product.

“Fluke innovates to solve customers’ problems, and FieldSense technology is just one example of that,” he said. “The common thread here has been that we develop products very closely with customers and are focused on providing solutions so that our customers can focus on the job at hand. Whether it’s with FieldSense or other technologies, Fluke will continue to develop solutions to keep the world up and running.”

More specifically, Wright said FieldSense technology has the opportunity to add new capabilities to a number of future products, with details to be announced later this year.

SILVER

TSI Inc. stepped up to the plate swinging for the fences with its AirPro Solutions® offering, winning over our group of contractor judges and securing the silver award in this category.

AirPro Solutions is composed of Micromanometer Model AP800, Velocity Meter Model AP500, the AirPro Mobile app, and a license manager website portal. A suite of plug-and-play thermoanemometer probes, which accompanies the AP500, can be used to measure air velocity, temperature, and relative humidity and calculate airflow, along with wet bulb and dew point temperatures. TSI’s mobile application software allows users to log and view data remotely, while the license manager website portal allows business owners to track calibration due dates, print out calibration certificates, and track which of their technicians are using which products. The AP800 and AP500 meters each include a small display with an On/Off button and Enter keys. The meters communicate real-time data via Bluetooth to the AirPro Mobile app, which is compatible with iOS and Android devices.

“AirPro Solutions speeds up the measuring process and reduces errors by eliminating manual calculations,” said Jim Schumacher, product specialist, TSI Inc. “The built-in duct traverse workflow eliminates measurement point guesswork. With AirPro Solutions, one technician can take simultaneous measurements in multiple locations with all information displayed on one smart device and quickly send data to others, eliminating handwritten notes and forms.”

BRONZE

The Testing and Monitoring bronze goes to the Insertion Electromagnetic Flow Transmitter from Dwyer Instruments Inc.

The Insertion Electromagnetic Flow Transmitter, Series IEF, is an adjustable insertion flowmeter, featuring electromagnetic technology that accurately and reliably measures fluid velocity while providing several continuous signal outputs.

One unit is adjustable to fit pipe sizes from 4 to 36 inches on most pipe materials with integrated glycol concentration compensation.

“Each unit is calibrated on multiple line sizes so that a technician can easily field set a unit for their specific application,” said Val Kesler, product manager — level and flow, Dwyer. “Instead of waiting weeks for a new transmitter to arrive, one stocked part is adjustable for various pipe sizes. An easy-to-follow menu walks a technician through the process of accurately measuring the wall thickness and circumference in order to determine the ideal installation depth in the pipe.”

Future plans for the Insertion Electromagnetic Flow Transmitter include integrating Btu capability to the unit and offering remote display capability.

Publication date: 7/23/2018

Want more HVAC industry news and information? Join The NEWS on Facebook, Twitter, and LinkedIn today!

Report Abusive Comment