Refrigeration

Products being redesigned in light of new efficiency standards, refrigerant changes

Read More

Proper Ice Machine Cleaning and Maintenance

Good practices enhance food safety, extend equipment life

Read More

Cooler, Freezer Manufacturers Refocus on Customers’ Desires

Market demand rather than government regulations is now driving product development

Read More

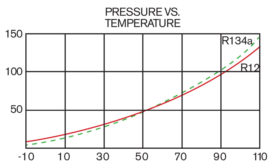

The Professor: Global Warming Scares Costing Us Some Popular Refrigerants

Many refrigerants have been delisted in certain applications

Read More

Ice Breaker: Troubleshooting an Iced Evaporator

Spotting an iced-up evaporator is easy, though determining how it got that way is tougher

Read More

How to Manage an OSHA Inspection, Part 1

Simple steps to ensure your facility and people are well-prepared

Read More

New Refrigeration Motor Cuts Supermarket Energy Usage

DOE verified demos show energy savings of up to 80%

July 4, 2016

Aircell System Claims 50% Energy Savings for Open Refrigerated Cases

Adande publishes research that it says proves significant energy benefit and temperature control

Read More

AHRI Removes Paint Color Assignments for Refrigerant Containers

Revisions to Guideline N specify light green-gray on all containers by 2020

July 4, 2016

A Look Inside Airgas Refrigerants’ Refrigerant Test Lab

New facility designed for flow, flexibility, and safety

July 4, 2016

Copyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing