As it turns out, there was a huge opportunity in the residential unitary market for more sophisticated diagnostics and controls. The benefits are big game indeed: reduced warranty claims, lower utility bills, improved comfort, and greater customer satisfaction, all wrapped up in improved system diagnostics.

Emerson Climate Technologies has been among the leaders in both studying reasons for in-warranty returns, and providing systems-based solutions. Products such as the recently introduced UltraTech™ and slightly older Comfort Alert™ keep track of operational parameters, notify occupants of potential problems, and help servicers ensure that they are barking up the right diagnostic tree.

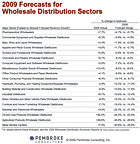

Code 1 fault: This graph shows the probability of a unitary system fault, which increases over time as it is detected by Comfort Alert.

A SMART TREND

The system combines a two-stage Copeland® UltraTech scroll compressor and its outdoor control board with an indoor control board and White-Rodgers® UltraTech programmable thermostat. The entire system can share information system-wide, autoconfiguring and checking system settings with no additional wires.According to John Schneider, director of marketing, Emerson Climate Technologies Residential Systems, the smart HVAC trend is a hot one. But is there a consumer demand for it?

“There are some consumer dynamics, such as energy efficiency needs,” Schneider said. “Systems tend to become more complex to deliver more than 13 SEER efficiency.”

The other dynamic, he said, is consumer awareness. “They talk a lot about comfort as a key need, but they don’t really know about the solutions. Contractors are raising homeowner awareness. Smart HVAC will be able to raise homeowner awareness even more.”

Products like UltraTech send messages to different nodes of the system; it can share information system-wide, allowing contractors to autoconfigure system settings. It can automatically adjust settings for specific equipment, and reach out and gather information from the system, Schneider said.

“Now you have these components reaching out to other parts of the system,” he continued, “taking system diagnostics to a whole other level. It’s unique in that it uses the Copeland Scroll to do the diagnostics. What we’ve actually done is embedded Comfort Alert on that comfort system.”

Studies from Emerson Climate Technologies show that the degree of technicians’ troubleshooting accuracy can increase dramatically when they use built-in system diagnostics.

TROUBLESHOOTING PROWESS

This provides more detailed information. “Now we can specifically say if we have a low-side or high-side fault, for instance. We have more specific information for the contractor.”The contractor has instant access to the system’s fault history. The communicating thermostat lets the homeowner know there is a reason to call their contractor, but the system doesn’t give so much information that it might tempt some homeowners to try to fix the problem themselves. An active protection feature can shut down the system if a severe fault is damaging the system, likewise sending the homeowner a message to call for service. Homeowners can override this feature, Schneider said. It’s not a lockout, but it gives the homeowner ample warning that a serious problem has occurred.

These are the key components of Emerson Climate Technologies’ Comfort Alert, a diagnostic system component that helps technicians pinpoint problem areas.

Setting the proper airflow in particular can benefit from autoconfiguring. However, “This doesn’t replace the need for the skills that a contractor brings to the table,” Schneider said. “We find that in general, it gives the contractor confidence that the system he installed is set up properly.”

The system also features some nifty built-in redundancy. “Say that several years from now the unitary control on the outdoor unit is replaced. That board gets autoconfigured by the other nodes still in the system. Information resides on the other nodes.”

This is the wiring schematic for Emerson Climate Technologies’ Comfort Alert. The schematic shows how the system can be wired in for aftermarket installations.

HISTORY COUNTS

Kelvin Kleman, engineering manager, electronics and controls for Rheem A/C, said the company’s Comfort Control System (CCS) limits troubleshooting information very carefully. “If the tech wants to troubleshoot, he checks the local diagnostics in the outdoor unit.” A seven-segment display shows the troubleshooting code so the tech doesn’t have to “sit there counting blinks,” Kleman said.A fault recall feature also saves technicians time by not making them play the wait-and-see game. “We’ve all seen cases where you get the service guy out there and everything’s fine,” Kleman said. With CCS, the tech can push a few buttons to check for a fault recall. “If he’s had a low-pressure trip, it will come up as the number 21,” Kleman said. “He can start his analysis based on that low-pressure trip. It really directs him. “A lot of today’s basic systems don’t have low- and high-pressure switches in them,” he continued. “They’re usually wired in series with the compressor contactor.” The tech could have a long series of things to evaluate before he finds the root cause.

He agreed that good technical HVAC skills are still necessary to work with smart diagnostics. “These guys still need to have a basic skill to follow the problem.” But the diagnostic “gives him in-depth information, rather than him just walking out there and finding that the compressor doesn’t run.”

Publication date:03/05/2007