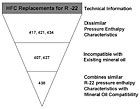

This diagram clarifies the major differences between R-22 replacement refrigerants based on years of DuPont laboratory and field experience.

The Environmental Protection Agency (EPA) has endorsed several acceptable alternatives to R-22, and some businesses have already started to transition to those refrigerants. Before any retrofit takes place, however, end users and contractors need to research which refrigerant to use, as well as how that refrigerant will affect the existing commercial refrigeration equipment. Refrigerant manufacturers weigh in on this debate by outlining the challenges end users and contractors may face during the phaseout, as well as details on the various types of alternative refrigerants currently available.

CHALLENGES AWAIT

There is no question that the HCFC phaseout will impact the commercial refrigeration market. Starting in January 2010, the HCFC consumption cap will be reduced by 58 percent from 2009 levels, significantly reducing the amount of production and imports of R-22 in the United States.Based on EPA estimated service demand, this significant reduction in R-22 has the potential to create a 27.5-million-pound supply shortfall in 2010. This potential shortfall poses a risk to contractors and equipment owners who service and operate equipment that uses R-22, noted Joyce Wallace, North America marketing manager, DuPont Refrigerants, Wilmington, Del.

Wallace noted that several factors could reduce the potential severity of the shortfall, including the following:

• Additional R-22 supply due to fourth-quarter inventory build throughout the supply chain and/or accelerated conversions to new equipment.

• Reduced R-22 demand due to reduced leak rates and improved service practices, and/or increased recovery, recycle, and reclaim practices.

“While there is some uncertainty around the R-22 supply and demand market dynamics, one thing that is certain is the implementation of the HCFC consumption cap as of January 2010,” said Wallace. “Given the significance of the drop-in R-22 consumption cap, having a viable refrigerant management plan that protects the equipment owner from supply interruption and the possibility of volatile shifts in R-22 pricing is an essential part of an effective business plan for commercial refrigeration.”

With the elimination of R-22 in new commercial refrigeration equipment, owners will also have to start adapting to new HFC-based equipment, stated Gus Rolotti, technical marketing director, Arkema, Inc., King of Prussia, Pa. “Most equipment owners have already completed at least a partial transition to HFC-based equipment using refrigerants such as R-404A, R-507A, and R-134a. Equipment owners also may retrofit existing systems to HFC refrigerants such as R-427A. Finally, users of existing R-22 equipment should understand that R-22 is still allowed for service of existing units through 2020.”

Gordon L. McKinney, vice president/COO, ICOR International, Inc., Indianapolis, noted that the HCFC phaseout will most likely drive up the price on mainstream refrigerants such as R-22 and other interim alternatives that contain an HCFC.

“Equipment owners will be weighing their options carefully, but my guess is that unless the economy rebounds in very short order, most equipment owners will opt to repair rather than replace. Since there are a number of non-ozone-depleting HFC replacements for R-22 now available, existing R-22-designed equipment can be maintained for many years to come.”

The type of alternative that should be used in a system will depend greatly on the application. DuPont’s Isceon® MO99™ can be used across a wide-range of evaporator temperatures. (Photo courtesy of DuPont.)

AVAILBLE ALTERNATIVES

Speaking of replacement, there are a host of different fluids that can be used instead of HCFCs, and each has performance pluses and minuses, said Chris LaPietra, marketing manager, Honeywell Genetron Refrigerants, Morristown, N.J.“Honeywell markets several HCFC alternatives that provide benefits such as good operating performance, no need for an oil change, and no need to adjust TXV valves. Differences in equipment design dictate different solutions; for example, it may be possible to successfully retrofit a piece of equipment that has oil separation technology with an HFC/HC and retain the original mineral oil, while the same blend will not perform well in equipment with vertical suction risers. Each retrofit customer is different, so we try to aim our products at the needs of different market segments.”

Alternative refrigerants can usually be applied to existing equipment, although differing degrees of modification will be needed. LaPietra noted that equipment owners should ask the following key questions before embarking on any retrofit:

• How efficient is the retrofit refrigerant?

• What is the capacity of the retrofit refrigerant?

• Will the retrofit refrigerant require a TXV change or adjustment?

• Will the retrofit refrigerant require an oil change?

• What is the global warming potential of the retrofit fluid versus the current HCFC?

Be aware that alternative refrigerants may not have the same performance characteristics as the refrigerant currently in use, warned LaPietra.

“There is a lot of talk about R-22 retrofits that will make systems perform the same as or better than R-22. Whenever such a statement is made, contractors and end users should start asking a lot of questions of the organization making the claim. Systems that were designed and optimized for R-22 will not perform the same with a retrofit refrigerant.

“Also keep in mind that the routine ‘tuneup’ that occurs during a retrofit will help improve performance. This performance benefit, however, would occur regardless of the refrigerant and should be included as part of a routine maintenance process.”

If the equipment is designed for a HCFC, chances are that using a HFC in that same system will impact the performance since the systems are not optimized for them, noted Rolotti. “Some refrigerants will have a greater performance difference than others, so owners will need to carefully evaluate the technical information to make educated decisions. For new equipment, since it can be specially designed and optimized for the new refrigerants, the new equipment with HFCs should be able to outperform similar equipment using HCFC.”

Rolotti noted that refrigerants such as Arkema’s Forane® 427A are designed to make the retrofit work easier, but there may be a small compromise in performance. Other refrigerants, such as R-404A, R-507A for low temperature or R-134a and R-407A can also be used but will require more elaborate changeover procedures, such as changing oils or possibly replacing expansion devices, he added.

ICOR offers its NU-22B® (R-422B) as a direct replacement for R-22 in medium-temperature refrigeration or air conditioning applications. “NU-22B is a non-ozone-depleting, nontoxic, nonflammable HFC and carries an A1 ASHRAE [American Society of Heating, Refrigerating, and Air-Conditioning Engineers] safety classification,” said McKinney.

“Since NU-22B’s operating characteristics closely resemble those of R-22, there are no major system modifications required. And unlike most HFCs, NU-22B is designed to work with standard mineral oil and therefore does not require a full or partial POE oil change.”

Another product from ICOR, One Shot®C (R-422C), is a non-ozone-depleting, nontoxic, non-flammable HFC designed for use as a direct replacement for R-502. McKinney stated that this replacement does not require any system modifications or oil changes.

“One Shot can also be used to replace R-22 in low-temperature refrigeration applications with only minor retrofit procedures required.”

The type of alternative that should be used will depend greatly on the application, as most refrigerants are not universally applicable across multiple evaporator temperatures, noted Wallace.

“One of the benefits of our newest product, Isceon® MO99™ is that it can be used across a wide range of evaporator temperatures. Isceon® MO99 is mineral oil-compatible and has R-22 pressure enthalpy characteristics, making it the lowest cost retrofit option. Extensive market feedback confirms that contractors prefer not to deal with the complexities and costs associated with POE oil as well as recent reports of plugging from partial POE alternatives.”

Cylinders are filled with R-410A, as the HVAC industry counts down to the January 2010 phaseout of R-22 in new equipment. (Photo courtesy of Arkema.)

WORDS OF WISDOM

The impending phaseout of R-22 will most likely raise concerns and questions among end users of commercial refrigeration equipment. Contractors can help allay their fears by providing information and suggestions on ways to cope with the new rules and regulations.Due to the complexity of refrigeration systems and the broad variety of applications, contractors can help equipment owners carefully consider their unique situation. Rolotti noted that the first step is for end users to understand the regulations related to HCFC phaseout, and those have been detailed in numerous articles and discussions that contractors can share.

“The second step is to review the status of their existing HCFC equipment,” said Rolotti. “Factors such as the type and age of equipment will help determine which option to choose for the phaseout of R-22. The third step is for end users to discuss the situation with not only their contractor, but their equipment manufacturer, local wholesaler, and possibly a refrigerant manufacturer to receive a broad range of information to help make an informed decision. There are also many Websites, such as www.phaseoutfacts.org, that provide a broad range of information for equipment owners.”

McKinney cautions end users to weigh their options carefully. “Some HCFC alternatives have already been in use for several years now, so end users should request referrals and case studies on systems and applications similar to their own. Most importantly, end users should be sure that any system selected for conversion is in good operational condition prior to conversion. Converting a system to an alternative refrigerant will not cure any existing operational deficiencies.”

For applications with large amounts of refrigeration equipment, it is extremely important to have a comprehensive refrigerant management plan to transition away from R-22, said Wallace. This plan should focus on improved service practices including reduced leak rates; equipment replacement and retrofit; and recovery, recycle and reclaim programs.

“Contractors can help large equipment owners by doing their homework in advance, including working with select retrofit refrigerants to gain first-hand experience before the anticipated R-22 shortfall occurs. This will help them be ready to confidently recommend the best performing, lowest overall cost retrofit option, providing invaluable service to their customers for orderly and smooth transition away from R-22,” she said.

The phaseout of R-22 will no doubt cause some concern among end users of commercial refrigeration equipment, and they will be looking to their contractors to guide them through this time of transition. It’s a golden opportunity for contractors to share their wisdom and make themselves even more indispensable to their clients.

Publication date:10/05/2009