ARLINGTON, Texas — Thanks to stimulus funding, the University of Texas Arlington has commissioned two new high-efficiency chillers that will serve the main campus cooling loop and provide projected annual energy savings of nearly $200,000. The York® chillers were manufactured by Johnson Controls. The chiller replacement project is one of six major projects on the University of Texas Arlington campus funded by the Texas State Energy Conservation Office (SECO).

ARLINGTON, Texas — Thanks to stimulus funding, the University of Texas Arlington has commissioned two new high-efficiency chillers that will serve the main campus cooling loop and provide projected annual energy savings of nearly $200,000. The York® chillers were manufactured by Johnson Controls. The chiller replacement project is one of six major projects on the University of Texas Arlington campus funded by the Texas State Energy Conservation Office (SECO).“The university is in an exciting period of growth, with a number of major projects underway across the campus,” said Larry Harrison, director of University of Texas Arlington Mechanical Operations and Grounds. The university opened the 234,000-square-foot Engineering Research Building in January and is developing more than 20 acres at the College Park District, including the 6,500-seat College Park Center and a mixed-use residential and retail center called College Park.

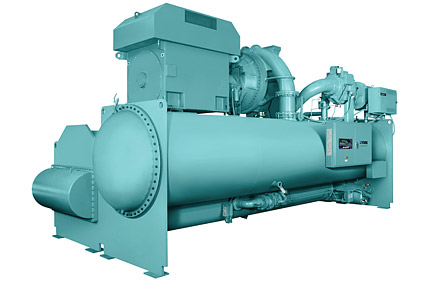

The University opted to replace two 3,000 TR chillers, which were charged with HCFC-22 refrigerant, to meet the requirements of the research facilities. The replacements were two new 3,000 TR, high-efficiency, York model YK-EP centrifugal chillers charged with HFC-134a refrigerant, which has zero ozone-depletion potential.

“With the university’s advanced research facilities, it is extremely important that we have highly reliable and dependable chillers,” Harrison said. “We simply cannot afford any downtime, and in those rare cases when there is downtime, we need to get back online as quickly as possible.”

The YK-EP chillers feature compressor drivelines with industrial-grade open motors, which mean less downtime, said Johnson Controls. If a motor failure occurs, the chiller can be brought back online faster and at a reduced cost, when compared with chillers that utilize hermetic motors, the company said.

The benefits realized by the university as a result of installing the YK-EP chiller were summarized by Bill Blair of Texas Air Systems, sales agent for Johnson Controls, “The YK-EP chillers were the best option for UTA because of their high efficiency at both design and off-design conditions, and the reliability provided by their open motors.”

TDIndustries, one of the largest mechanical contractors in north and southwest Texas, helped secure funding for the project from SECO, targeting money that is designated for state projects that meet specific payback criteria. For the balance of the funding, University of Texas Arlington and TDIndustries entered into a performance contract, whereby the energy savings would pay for the improvements. The savings for the entire project are projected to be over $1.1 million a year.

Barry Whaley, TD account executive, said, “Our project at UT Arlington addresses not only energy-cost reduction through equipment replacement, but also the university’s need to upgrade its infrastructure to provide increased systems reliability. Other elements of the project will help the university save energy by providing our Continuous Commissioning® services over the life of the program — insuring the persistence of the projected savings.”

In addition to the two new YK-EP chillers, the main plant at the university includes two 2,000 TR York model YK centrifugal chillers and one 3,400 TR York model YD centrifugal chiller. “The reason we have loved York chillers is simply because they are reliable units,” Harrison said.

For more information on York chillers, visit www.johnsoncontrols.com/chillers.

Publication date: 09/05/2011