|

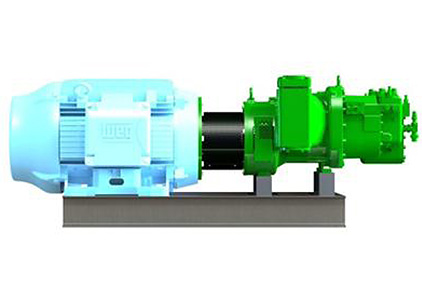

| Bitzer ammonia screw compressor. (Photo courtesy Bitzer US Inc.) |

According to the company, it had long marketed its line of bare open drive reciprocating and screw compressors for ammonia applications, but at the show the company announced it was assembling ammonia packages ranging from simple motor-compressor combinations on rails up to complete rotary screw compressor packages.

The single compressor rotary screw packages consist of R-717 (ammonia) in medium temp 24 to 150 TR, low temp 15 to 75 TR, with up to three compressors per package, custom engineered to customer specifications, and a PLC controller with open protocol.

Regarding the NH3 screw compressors, the company said they are available in 20 to 300 hp, designed in Germany, optimized for parallel operation with energy-efficient rotor profiles, and with advanced geometry and stability.

Regarding the NH3 reciprocating compressors, the company noted the compressors are 5 to 60 hp direct drive or belt drive, designed in Germany, easy to apply to booster applications, have high-quality shaft seals, with water-cooled heads as standard, and are optimized for parallel operation.

Art Mathews, Bitzer business development manager for industrial products, said that the company is filling a void in the marketplace for small ammonia systems.

“Historically, ammonia compressors have been large CFH models like those found in refrigerated warehouses,” he said. “But the trend now is to reduce the ammonia charge in systems and provide multiple, self-contained systems to handle the loads.”

He said the company is moving its current semi-hermetic reciprocating compressor production into a new 90,000-square-foot plant beside its current plant in Oakwood, Ga., and its production of its ASME-certified pressure vessels and ammonia refrigeration packages was moved to the plant in January.

Publication date: 2/25/2013