A tradeoff has always existed between the water temperature at which hydronic heat emitters are sized and their cost. The higher the supply water temperature assumed by the designer, the smaller the required heat emitters and the lower their installed cost. This is why the heat output tables on some baseboards did, and in some cases still do, list heat outputs at water temperatures all the way up to 240˚F.

A tradeoff has always existed between the water temperature at which hydronic heat emitters are sized and their cost. The higher the supply water temperature assumed by the designer, the smaller the required heat emitters and the lower their installed cost. This is why the heat output tables on some baseboards did, and in some cases still do, list heat outputs at water temperatures all the way up to 240˚F.

Although I’ve worked with hydronic heating for more than three decades and designed systems around just about every possible heat source, I would be hard pressed to predict what hydronic heat sources might be available 25 years from now. Fifty years from now I doubt that I will be predicting anything. Yet I hope that hydronic heating, in some form, will still exist and may even be the dominant method of heat delivery.

Longevity and Cost

By the latter half of the 20th century, the North American hydronics industry got used to the fact that some hydronic heat sources could last for several decades. It was not uncommon for a well-applied cast-iron boiler to have a useful life of 30-40 years. These boilers usually became technologically obsolete before they were incapable of operating due to some major failure. This was just fine when fuel prices were reasonably cheap and stable, and product development occurred at a somewhat slower pace compared to today. Back then, most Americans cared little about the box in the basement, provided that it responded when the dial on the T-86 got turned up in the fall.

Today, some fuel costs are approaching 400 percent of what they were 15 years ago. Predictably, more consumers are now interested in what’s happening within that box in the basement. Our industry has responded with a wide spectrum of heat sources from boilers to heat pumps to solar collectors. Still, you won’t find many manufacturers suggesting that these heat sources are likely to last more than 20 years.

To attain high thermal efficiency, most of these heat sources need to operate with low-temperature hydronic distribution systems. These include radiant floors, walls, and ceilings; panel radiators; or some of the newer low-temperature baseboard.

The hardware used in these distribution systems includes a wide range of polymer tubing (e.g., PEX, PEX-AL-PEX, PERT, PERT-AL-PERT, PP-R), as well as copper, steel, and aluminum.

Other materials used in site-built radiant panels include concrete, poured gypsum underlayment, foam insulation, fiberglass insulation, and wood. When properly selected and installed, modern hydronic distribution systems made from these materials should last for many decades, perhaps even as long as the building they are installed in.

Developing a Plan

So, based on expected life, it appears inevitable that most of the hydronic distribution systems currently being installed will be

supplied by different heat sources over their useful lives. This raises an obvious question: What can designers do today to ensure that the distribution systems they create are compatible with future heat sources?

The answer should consider the materials used in the system, how the system will be maintained, and at what conditions the system will operate.

Regarding materials, most of the present-day polymer tubes, when applied at temperatures and pressures well-below their maximum ratings, should last upwards of 100 years. I’ve even heard speculation of 200-year lifetimes for PEX. To achieve such longevity, these materials should be installed so that they are not abraded due to expansion/contraction movement. They also should be protected from ultraviolet light and not exposed to hydrocarbon solvents.

Copper and copper alloys such as brass should not be exposed to acids such as those contained in residual soldering flux or degraded glycol antifreeze. They also should not be exposed to water with high concentrations of hydrogen sulfide. Flow velocities in copper tubing should be limited to 4 feet per second. All piping circuits containing steel, soldered-copper, or threaded-iron piping should be internally cleaned with proper hydronic detergents, such as those available from Fernox and Rhomar. This removes residual solder flux and cutting oils that would otherwise remain in the system and potentially cause corrosion or impaired thermal performance due to fouled heat-transfer surfaces.

From the standpoint of design, the concept can be summarized with three words: low water temperature. The one prediction I am willing to make about future hydronic heat sources is that they will operate best at low water temperatures. So, when you size up radiant panels, panel radiators, or even baseboard, I suggest that you consider supply water temperatures no higher than 120º at design load conditions.

Deep-Energy Retrofit

We recently went through this exercise when designing a hydronic system for a New England home originally built in the late 1700s. The exterior shell of this house went through a deep-energy retrofit that, in combination with a new addition, brought the theoretical design load of 5,000 square feet of heated living space and tempered basement under 30,000 Btuh. Several layers of foam insulation, as well as an air infiltration barrier, were added to the outside of the original post and beam frame.

The new hydronic distribution system is a mixture of slab heating in the basement (more than 4 inches of extruded polystyrene underslab insulation) and panel radiators equipped with wireless thermostatic valves on the first and second floors.

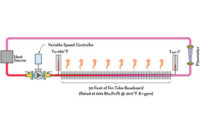

The first heat source installed to supply this new distribution system is a wall-hung mod/con boiler with a stainless steel firetube heat exchanger. It will be fueled with propane because natural gas is not available at the site.

The owner of this house is a forward-thinking person. He has already made a substantial investment in converting the thermal envelope of this structure into one that is more efficient than most newly built houses. Although the present plans don’t include them, he is mindful that renewable energy sources, such as solar thermal collectors and heat pumps, may someday be used in this house. It may happen in five years or 20 years. Whatever the timing, both the owner and I wanted to be sure the balance of systems was capable of operating with these, or even other heat sources, that may come along in the future.

With this in mind, we made sure the distribution system was designed for supply water temperature no higher than 120º at design load conditions. As such it stands ready, willing, and able to be retrofitted with potential future heat sources.

We also used simple controls such as wireless thermostatic radiator valves and a motorized three-way mixing valve. We avoided using complex electronic controllers that are likely to be far from state of the art and perhaps even farther from serviceable in 25 years. We used oxygen-tight PEX-AL-PEX tubing, configured in a home-run distribution system, to supply each panel radiator. A dual isolation valve was installed at each radiator to allow isolation, removal, and replacement if ever necessary.

A buffer tank was installed to keep the boiler from short cycling under low load conditions, or when only one or two panel radiators need heat. Flow is controlled by a small pressure-regulated, ECM [electronically commutated motor]-based circulator. The entire system will be flushed with a hydronic detergent as part of the commissioning process.

I urge those who design hydronic systems to think carefully about what your systems will look like in 25 years. Will those who install the next heat source in these systems see that you considered the long lifespan of a well-planned and easily maintained distribution system? Or will they find it necessary to shoehorn in supplemental heat emitters? Will the controls that operate this system still work, or will they add to the growing tonnage of electronic waste we are already producing?

Do what you can now to future-proof the hydronic distributions systems you create. Those who follow will appreciate the forethought.

Publication date: 5/13/2013