Now, Bob’s company has promoted him to help train a new employee, right out of a school specializing in HVAC, just like Bob was. Bob is now Tim’s Btu Buddy. Tim is anxious to travel with Bob. Tim realizes that he is right out of school, with the theory and lab work that he accomplished in school, but still needs help. He knows that he worked with many of the components of the systems in the school, under ideal conditions with good light and air conditioning. Now it is into the field, sometimes under the house with poor lighting, or out on the rooftop in the sun, where the real action is. He is naturally and normally reluctant, but he has Bob to help guide him.

Bob and Tim were on their way to a no cooling call at a commercial building location. This is a large manufacturing plant that has a number of installations. It is an old customer as well as a good customer of the company.

They arrive and talk to the maintenance man and he tells them which unit it is and goes with them to the area that the unit serves. It is a large room served by a 20-ton split system. The unit is probably 10 years old. When they arrive at the room, it is obvious that the unit is not working. They notice that the fan is running and blowing plenty of air, but the room is hot. The fact that the fan is running tells them that the control voltage is working. They examine the thermostat and it is calling for cooling, so they decide to go to the roof and see what the condensing unit is doing.

They have to climb a ladder through a roof hatch to get to the condensing unit.

As they were walking across the roof, they heard the unit’s fans running. They made a lot of noise and Tim commented, “Boy, those fans are noisy.”

When they walked up to the unit, Bob said, “Not only are the fans noisy, look at the oil and dust all over the condenser tubes and fins.”

Jose, the maintenance man, said, “We have had a lot of problems with this unit in the last few months. We have added refrigerant, repaired leaks, and worked on the fans. It just keeps breaking down.”

They took the panels off of the compressor compartment for an inspection. The compressor was not running so they started looking to see why it wasn’t operating.

Tim checked the compressor contactor and it was closed, so the problem was likely in the compressor. He then reached for the disconnect switch to shut the unit off when Bob suggested, “Tim, I think you should shut the unit off using the control wiring rather than using the disconnect. This is a rather large unit to use the disconnect to shut it down, even though the compressor is not running.”

Tim then said, “You are right; it is best to use the control circuit. Disconnect switches are really not designed for everyday use to stop and start motors.”

After the unit was shut down, Tim removed the terminal box cover and performed an ohm check of the three-phase compressor motor and found that the motor windings appeared to be good (Figure 1). He said, “The motor ohms out good, and the compressor is hot to the touch. What is going on?”

Bob said, “Replace the terminal box cover and start the unit again.”

Tim started the unit again and said, “The compressor is still not running. I don’t understand.”

Bob said, “Use your ammeter to check the amperage of the compressor.”

Tim put his clamp-on ammeter around one of the wires and said, “It is drawing three amps, but it is not running. I am going to check all three compressor leads for current.”

After checking all three leads, he said, “They are all pulling three amps. What is going on?”

Bob explained, “I think that the compressor crankshaft is broken. The motor has no load on it and is just turning too easy to pull much current or make any sound. One way to tell for sure is to start the unit again and check the locked rotor amperage on start up. Clamp the meter on one leg and stop the unit for a few minutes to let the motor coast to a stop and then start it up again. Then see what the amperage is.”

Tim shut the unit off and they stood around a few minutes and he started it again. The amperage jumped up during startup and quickly dropped down to three amps again.

Bob said, “The compressor is no good and will have to be changed, but when I look at the condition of this unit, I hesitate to put a new compressor in it. The fans are out of balance; the blades are bent. I doubt if we could get them to work correctly, or find replacements. The coil has many leaks in it, I suppose because of all of the vibration, and I doubt if it could be repaired.”

Jose then suggested, “We have another one these exact units over on another building that will probably never be used. What if we move that condenser over here and install it? It is a good unit that was running great with no troubles when we quit using it.”

Bob said, “That sounds good to me. Let’s get started getting the refrigerant out of these units. We will start with the unit on the other building by recovering the refrigerant and capping the piping off. Then we will move it to here and disconnect this unit and install the other unit here.”

Tim then asked, “How do we know that the replacement unit is in good shape? It seems to me that we should start it up to make sure.”

Bob said, “That is a good point, Tim. We will run the system and make sure that the pressures are correct, then we will recover the refrigerant, and then we will pressure the whole system to about 5 psig with nitrogen (Figure 2). When we get the condenser disconnected, we will cap the liquid line and the suction line to the old evaporator section and it will be good to use again if the need ever occurs.”

Fortunately, the power had been left on at the other unit and the crankcase heater had the compressor warm. This was an R-22 unit, so it was important for the heat to be on the crankcase to prevent liquid refrigerant migration to the compressor crankcase. They started the unit up and the pressures were normal for the conditions. They connected the recovery unit to the system and recovered the refrigerant and then pushed a nitrogen charge into the system to about 5 psig. They front seated the “king” valve and the suction service valve, trapping the nitrogen in the system until it was installed in the new location.

They now had the replacement unit ready to install and the unit to be replaced ready to disconnect. The replacement unit was still in place. They would have to move it to the new location.

Tim asked, “Why do you always leave nitrogen in these systems? It seems like a lot of work raising the nitrogen cylinder to the roof and moving it all over the place.”

Bob explained, “When we recovered the refrigerant from the old unit, the system was in a vacuum. If we just cut the pipes loose, atmosphere would enter the system when we cut the pipes. We are going to use the old evaporator with the replacement condensing unit and we do not want it polluted with air and moisture. The evaporator that we left at the location where we disconnected the replacement condensing unit may be used in the future. We never know, so we left it with a nitrogen charge so that it will not be polluted if it is ever needed. It has always worked out for me to leave everything ready to use again.”

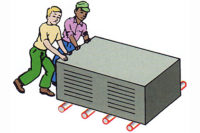

Tim then said, “Something new every day, this is great. How are we going to move the replacement unit to this location? It is a long ways across the roof and a crane will have a hard time reaching the unit.”

Bob said, “We will work on that tomorrow. I have plan.”

(Continued next month.)

Publication date: 5/20/2013

Want more HVAC industry news and information? Join The NEWS on Facebook, Twitter, and LinkedIn today!