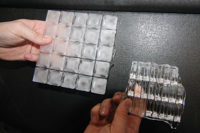

Often, a simple control scheme using a microprocessor can allow manufacturers to use lower starting torque compressors without the use of a hard start kit to operate their ice machines. Before the advent of the microprocessor, many ice machine manufacturers used capacitor-start/capacitor-run (CSCR) compressor motors in their equipment. CSCR compressor motors used a potential relay, a start capacitor, and a run capacitor to help get started against uneven system pressures. These components were often referred to as a “hard-start-kit” (Figure 1).

Hard start kits were effective, giving the CSCR motor relatively high-starting and good running torque. The potential relay consisted of a normally closed set of contacts and a high-resistance coil. At the instant of start, both the start and run capacitors are in parallel with one another while at the same time being in series with the start winding.

Parallel capacitors have more plate surface areas for electrons to collect on, giving them greater capacitance while in parallel. In fact, the capacitance of capacitors adds when wired in parallel. This causes a large phase shift between the run and start windings, giving the motor good starting torque. Once running, the start capacitor dropped out of the circuit with the help of the relay coil and contacts. The motor now becomes a permanent split capacitance (PSC) motor. The run capacitor alone is now in series with the start winding during the entire running cycle, giving the motor good running torque. (Figure 2 - Click here to view an electrical diagram of a CSCR motor with a potential relay.)

The relay contact and coil are all components that, in time, could fail because they are electro-mechanical devices with moving parts. The high-resistance coil could burn out and open-circuit or short to ground. The contacts could stick in the closed or open position, causing damage to the motor windings. The start or run capacitor could open-circuit or short to ground and cause motor winding damage, rendering the ice machine useless.

Solid-state Relays

When a microprocessor is incorporated in the control scheme, lower torque compressor motors with solid-state starting relays can be used by the ice machine manufacturer. This allows for a less expensive compressor motor and a more reliable starting relay for the compressor. The solid-state relay has no moving parts. It is basically a ceramic-type resistor that varies its resistance as its temperature changes. At room temperature, the resistor has a very low resistance. As its temperature increases, its resistance greatly increases, giving it a positive temperature coefficient. The low resistance at room temperature lets current pass very easily. However, when hot, the resistor’s very high resistance simulates an open circuit to current flow. These devices are often referred to as solid state relays or positive temperature coefficient resistors (PTCRs, see Figure 3). With no armature, contacts, or coil to contend with, the solid-state relay is more reliable. In addition, only a run capacitor is used in the starting circuit. (Figure 4 - Click here to view an electrical diagram of a PTCR and a run capacitor.)

Operation

When the operating control calls for cooling, the PTCR is cool and has very low resistance. This allows a large inrush of current through the start winding and the PTCR. The run capacitor is actually momentarily shunted out by the PTCR circuit. The run winding will also see a large inrush of current because it has a low impedance when the motor’s rotor is not turning. Because the run and start windings have different impedance values, a phase shift is developed between them. This phase shift causes torque and the motor’s rotor starts to turn. In the meantime, the large inrush of current through the PTCR causes it to get very hot. Its resistance will now greatly increase, stopping almost all of the current flow through the PTCR. The motor is now running as a PSC motor with the run capacitor in series with the start winding. This action keeps a phase shift between the run and start winding, causing more running torque.

Control Sequence

Often, this starting sequence doesn’t give the motor quite enough starting torque to handle the large pressure differences refrigeration systems often have during their off cycles. This is where the microprocessor and a control sequence come into play. Energizing a hot gas solenoid for 45 seconds during the water purge while the compressor is off, and for 5 seconds while the compressor is on, gives the system’s unequal pressures a chance to become more equal.

Timing and control schemes can vary between manufacturers. Starting a system with equalized pressures requires a lot less starting torque from the motor. This smaller required starting torque can now be handled by a lower starting torque motor, a run capacitor, and a solid-state PTCR starting relay. However, if it were not for the hot gas solenoids being energized during the starting sequence, a CSCR motor would be required. The microprocessor can store these control sequences, or algorithms, in its memory on the motherboard itself (Figure 5).

Publication date: 10/6/2014

Want more HVAC industry news and information? Join The NEWS on Facebook, Twitter, and LinkedIn today!