Long before Americans had access to natural gas, propane, fuel oil, or electricity, and long before there were automatically controlled central heating systems, wood was the most commonly used heating fuel. The Alliance for Green Heat states the first evidence of wood-fueled heating occurred 1.4 million years ago, and the first European hearths date back about 500,000 years.

In early Americana, a wood-fired stove was the centerpiece of many kitchens. A parlor stove or fireplace provided comfort, albeit somewhat crude by today’s standards, in family gathering rooms.

As fossil fuels and electricity became increasingly available, most North Americans were easily persuaded to convert to modern means of central heating. The use of wood as a primary heating fuel was increasingly viewed as antiquated or limited to those who could not afford central heating.

The oil embargo of the 1970s, and the subsequent petroleum price shocks, rekindled interest in wood-fired stoves — at least as a supplemental form of heating. By 1979, a wood stove manufacturer named Vermont Castings made the Inc. 500 list of fastest-growing private companies in the U.S., doubling in size each year.

Unfortunately, that interest quickly declined when conventional fuel prices eased. Furthermore, after becoming accustomed to the luxury of automatic space heating, few “modern” Americans were willing to adapt the lifestyle required to successfully manage a manually fed wood-fired heating system.

New and Improved

Just as the solar thermal industry has had its ups and downs over the last four decades, the American public’s interest in wood-based heating has fluctuated with the price of conventional fuel. More recent factors that have revived interest in wood as a heating fuel include: significantly lower cost relative to fuels, such as No. 2 oil and propane; priority to keep money spent on energy in local economies; awareness of the carbon footprint associated with various conventional fuels; and concern over climate change.

In short, modern wood-based biomass heating systems offer benefits that now find favor with building owners, environmentalists, and even politicians.

Still, many Americans view wood-fired heating systems as the crude, dirty, and smoky pursuits of rural rednecks. The use of outdoor wood-fired heaters using single-stage combustion and, at times, the anything-that-fits-through-the-firebox-door fuel selections for these outdoor units has reinforced that image.

The feedback I’ve received suggests many of those working in the North American HVAC industry don’t consider wood an energy source that can, or should, compete with conventional fuels.

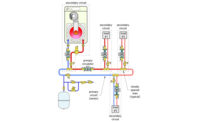

It’s the opposite in European countries, such as Austria, Germany, Sweden, and Switzerland, where high-tech biomass boilers fueled by wood chips and pellets are embraced as part of a responsible renewable energy portfolio. This attitude has led to committed research and development efforts significantly advancing wood-fueled heating technology. The best-in-class technology currently available to burn wood and wood-derived fuels has leapfrogged what was available in the 70s and 80s (see Figure 1a).

Today, residential- and commercial-size boilers using wood pellets can operate automatically for weeks. Depending on climate, these boilers may only require two or three ash removals per heating season. This simply involves detaching an ash box from the boiler and either emptying it in the trash or spreading it on your lawn or garden as fertilizer (see Figure 1b).

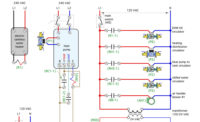

Many of these modern pellet-fueled boilers have integrated Web-accessible controls that can run the boiler as well as several peripheral devices, such as pellet transport systems, circulators, and mixing valves. Owners and service providers can monitor the entire system using smartphones or tablets.

This technology is steadily making its way to North America and is now ready to compete head-on with fuels such as No. 2 oil and propane.

Modern pellet-fired boilers can routinely achieve thermal efficiencies of 85 percent, as shown in Figure 2. When combined with secondary heat exchangers that allow condensation of water vapor in the exhaust gases, efficiencies can climb into the mid-90s. These boilers emit less than 5 percent of the particulate matter associated with a typical outdoor wood-fired heater using single-stage combustion.

New and revised regulations coming from state governments and the U.S. Environmental Protection Agency (EPA) are likely to stimulate this trend as they take aim at low-efficiency/high-emission wood burners. The EPA efforts, known as new source performance standards, are currently under revision and are likely to be patterned after strategies used for successful and widespread implementation of high-efficiency biomass heating devices in Europe.

Many manufacturers of wood-heating devices, as well as related trade associations, support the need for these revised regulations. They view them as an essential driver in gaining wood-fired heating devices widespread acceptance as a legitimate mainstream option for American consumers.

Did You Know?

Here are a few facts you might not have heard regarding modern, high-efficiency, wood-fueled hydronic heating systems:

• The cost of heat produced by burning wood pellets is currently about half that of heat produced by burning No. 2 fuel oil;

• The cost of heat produced by burning wood chips is about one quarter that of heat produced by burning No. 2 fuel oil at current prices;

• One ton of 35-40 percent moisture-content wood chips, combusted in a modern biomass boiler, can generate the same amount of heat as 61 gallons of No. 2 fuel oil;

• Wood is a carbon-neutral fuel. Burning wood does not increase the carbon dioxide added to the atmosphere. It simply releases the carbon that was removed from the atmosphere by photosynthesis as the tree grew. This carbon would eventually be returned to the atmosphere when the tree dies and decomposes in the forest. Think of the latter as “cold” combustion;

• Nearly all boilers fired by pellets, wood chips, and cordwood require properly sized thermal storage for optimal performance;

• Many wood-fired heating systems operate with compromised thermal efficiency due to boiler oversizing relative to design load;

• Pellet- and wood-chip-fired boilers can be modulated and staged for improved load matching. Some pellet-fired boilers can now achieve 10:1 turndown ratios (see Figure 3);

• Systems using high-efficiency wood-fired boilers benefit from using low-temperature heating distribution systems;

• Excellent opportunities are available for combining high-efficiency wood-fired boilers with other hydronic heat sources; and

• Several well-established hydronic subassemblies are ideally suited for use with high-efficiency wood-fired boilers (see Figure 4).

I’m very excited about the potential for high-efficiency biomass heating sources supported by modern hydronics technology. When properly executed, this combination allows use of renewable resources at high efficiency while delivering unsurpassed comfort, versatility, and a low operating cost.

I’ve long held that the future of hydronics will be closely linked to renewable energy heat sources. Biomass boilers are another example of such a partnership. If you’re involved in hydronic heating, you need to take a close look at what’s possible with modern biomass heat sources. They’re as different from their predecessors as your smartphone is from those rotary dial models of the 60s.

Publication date: 2/16/2015

Want more HVAC industry news and information? Join The NEWS on Facebook, Twitter, and LinkedIn today!