One of the more elusive causes of three-phase compressor motor overheating and failure is an imbalance in voltage.

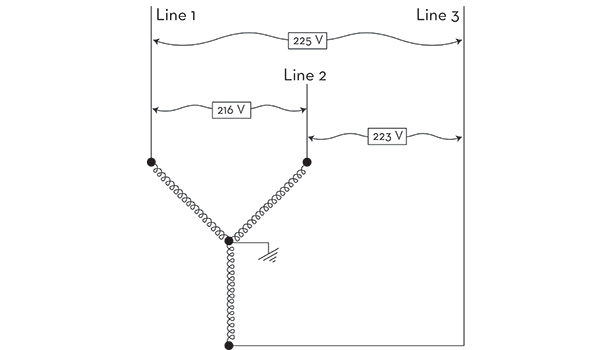

Compressor voltage unbalance can be found with a voltmeter by measuring between phases on the compressor’s motor terminals, at the compressor’s disconnect, or at the compressor’s contactor or starter terminals. Some of the more common configurations in three-phase motor windings are the Wye and Delta configurations (See Figure 1).

By measuring voltages between line 1 to line 2, line 2 to line 3, and line 3 to line 1, and performing a few simple mathematical calculations, a service technician can determine if there is a voltage unbalance. Voltage unbalances exceeding more than 2 percent in three-phase systems can cause current unbalance among the windings. These voltage and current unbalances can cause an increase in winding temperature and an overheating problem that can be detrimental to the motor.

An Example of Measuring Voltage Unbalance

(Refer to Figure 2 for the following examples)

Step No. 1: Measure line voltage between phases.

Line 1 to line 2 = 216 V

Line 2 to line 3 = 223 V

Line 1 to line 3 = 225 V

Step No. 2: Average the three line voltage readings.

216 V + 223 V + 225 V = 664 V

664 V ÷ 3 = 221.33 average V

Step No. 3: Find the unbalance for each phase by figuring the difference between each phase voltage (Step No. 1) and the average volts (Step No. 2).

Note: Make sure the subtraction comes out to be a positive number.

Line 1 to line 2 = 221.33 – 216 = 5.33 V

Line 2 to line 3 = 223 – 221.33 = 1.67 V

Line 1 to line 3 = 225 – 221.33 = 3.67 V

Step No. 4: Take the largest unbalance in Step No. 3, which in this case is 5.33 V, and divide it by the average volts found in Step No. 2. Multiplying by 100 puts it in a percentage form.

% Unbalance = (largest unbalance ÷ average volts) x 100

% Unbalance = (5.33 ÷ 221.33 ) x 100

Unbalance = 2.4 percent

As mentioned earlier, a voltage unbalance exceeding more than 2 percent in three-phase systems can cause excessive current unbalance among the windings. This above calculated voltage unbalance (2.4 percent) exceeds the 2 percent limit and can cause an increase in winding temperature that is detrimental to the motor. The following equation governs how voltage unbalance affects the temperature rise in the motor.

% Temperature Rise = 2 x (% Voltage Unbalanced)2

% Temperature Rise = 2 x (2.4)2

Temperature Rise = 11.52 percent

This equation shows that the voltage unbalance of 2.4 percent caused an 11.52 percent increase in winding temperature over the motor’s normal operating winding temperature. The building owner and local power company should be notified of the unbalance problem.

High Compression Ratios Also a Culprit

Compressor overheating can also be caused by high compression ratios. High compression ratios can be caused by high condensing pressures, low suction (evaporating) pressures, or a combination of both.

Causes for high condensing temperatures include:

• Dirty condenser coils;

• Restricted condenser airflow (fan out);

• Undersized condenser coil;

• Broken condenser fan belt;

• Recirculated air over the condenser;

• Air in the system;

• Overcharged system;

• Wrong or mixed refrigerant; and

• High ambient temperature.

Causes for low suction pressures include:

• Iced or frosted evaporator coils;

• Restricted evaporator airflow (fan out);

• Kinked suction line;

• Blocked suction line filter;

• Dirty or plugged liquid line filter drier;

• Kinked liquid line;

• Plugged compressor inlet screen;

• Defrost time clock burned out;

• Defrost heaters open circuit causing iced coils;

• Inappropriate defrost schedules;

• Undercharged system;

• Dirty evaporator coil;

• End of the running cycle;

• Thermostat or LPC set wrong; and

• Low heat load on the evaporator.

Publication date: 3/2/2015

Want more HVAC industry news and information? Join The NEWS on Facebook, Twitter, and LinkedIn today!