Many power-consuming devices such as single-phase motors are designed for dual-voltage operation. Figure 1 shows a solenoid valve with four different colored wires coming from its wire housing. Figure 2 is the wire housing cover that shows a technician how to connect the wires in order for the device to handle 120 V or 208-240 V.

Notice in Figure 2 that, for the solenoid to handle the lower voltage of 120 V, the red and blue wires would need to be connected, as would the black and yellow wires. 120-V power (120-V hot leg and a common) would then be brought to the wire bundles connected together. One bundle would receive the 120-V hot wire, and the other would receive the neutral wire. It makes no difference which one receives the hot or neutral wire.

The solenoid coil for a dual-voltage solenoid is actually made up of two separate coils, each designed to drop a voltage of 120 V. By connecting the coils in parallel, each coil drops 120 V (Figure 3).

Figure 2 also shows the solenoid coil wiring instructions for 240 V. The technician can accomplish this by connecting the red and yellow wires together and then connecting a 120-V hot leg to the blue wire. Another 120-V hot leg is connected to the black wire. This wiring arrangement connects the two solenoid coils in series, allowing each coil to again drop 120 V for a total of 240-V drop across both coils.

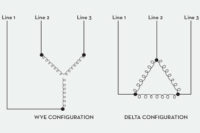

Many three-phase motors are also designed for dual voltages. Figure 4 shows a nine-lead, dual-voltage, three-phase motor’s wiring terminals. The motor is designed to handle voltages of 230 V and 460 V. The motor windings inside the motor actually are configured as in Figure 5.

Again, if the technician wants to wire the motor for the lower voltage of 230 V, the winding sets will have to be wired in parallel (Figure 6). This will cause each winding set to drop 230 V. However, if the technician wants to wire the motor to handle 460 V, the windings need to be wired in series (Figure 6). In either case, each winding is dropping 230 V.

Remember, when wiring motors for a certain voltage, the service technician must always refer to the motor manufacturer’s literature and numbering scheme before wiring the motor for the desired voltage or damage to the motor’s windings may occur.

Publication date: 3/30/2015

Want more HVAC industry news and information? Join The NEWS on Facebook, Twitter, and LinkedIn today!