Dutch emigration to the U.S. in the 19th century resulted in concentrations of people of Dutch origin residing in various parts of the U.S. — predominantly in the Northeast, Pacific Northwest, and the Midwest. In 1847, a group of some 800 Dutch émigrés founded Pella, Iowa, in the south central portion of the state. The legendary Earp brothers — Wyatt, Morgan, and Warren — were born in Pella. Today, the area retains examples of Dutch architecture and traditions (the city has an annual tulip festival and even a Dutch windmill), and some of its residents still speak a Dutch dialect called Pella Dutch.

Pella also boasts two large manufacturing companies — the window and door manufacturer, Pella, and Vermeer, a manufacturer of industrial equipment used in a variety of industries like agriculture, mining, utility installation, and forestry. Both companies were founded by Dutch community members and remain privately owned.

THE YELLOW IRON ACADEMY

Established in 1948, today, Vermeer serves customers in more than 60 countries and employs more than 2,500 individuals. At its main facility in Pella, the company operates a first shift that starts prior to 6 a.m., before community day care facilities typically open. To provide child care services to its employees with small children as well as parents in the community, Vermeer decided in 2011 to build an early-learning/day care facility on its 300-acre, nine-building “Vermeer Mile” campus. The facility, which is professionally managed and operated by Bright Horizons Family Solutions, opened in August 2014 and is heated and cooled using a geothermal system powered by Bosch Thermotechnology’s FHP heat pumps.

Called the Yellow Iron Academy (after the color of Vermeer machines), the three-building complex, designed by SVPA Architects of Des Moines, looks like an extended traditional barn with a silo attached to it. In addition to its main function as a child care facility, the building also provides a tornado storm shelter.

Selection of a geothermal-based HVAC system followed from a first use of geothermal for Vermeer’s data center building and the ability to use one of its own recently introduced pieces of equipment, the FX horizontal bore-drilling rig, to prepare a total of 40 geothermal bore holes at varying depths to a maximum of 30 feet adjacent to the new building.

USING GEOTHERMAL

“The site for the Academy was an open green field that lent itself to horizontal geothermal loops and allowed us to use our FX drilling equipment,” said Ed Beller, HVAC and electrical manager, Vermeer. A geothermal-equipped facility would also serve larger goals of the Vermeer family.

“We wanted a facility that would be energy efficient and environmentally friendly,” added Mindi VandenBosch, Vermeer’s continuous improvement manager and granddaughter of the company’s founder, Gary Vermeer, “and one that could facilitate ongoing education and discussions among students, parents, and the community about environmental awareness.”

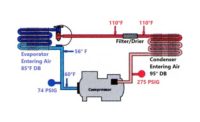

The geothermal system consists of 21 Bosch FHP ES two-stage and EP single-stage geothermal heat pumps. The Yellow Iron Academy building also comes with an energy recovery/geothermal unit to introduce outside ventilation air at 70°F; the other geothermal units then heat and cool the interior air. No backup HVAC components are needed as the heat pumps provide the entire load required. Hot gas reheat is used to dehumidify the inside air. Controls and sensors in the building monitor temperature/humidity levels for optimum comfort year-round.

“We designed 60 ton of total cooling using Bosch FHP heat pumps, from ½ to 5 ton installed in mechanical closets throughout the building,” comments Dave Inghram of KJWW Engineering Consultants’ Des Moines office. “No backup heat source is required — the geothermal heat pumps provide sufficient heating and cooling performance combined with a hot gas heat reheat to control humidity.”

GREEN, SUSTAINABLE FACILITY

Designed and built to U.S. Green Building Council (USGBC) Leadership in Energy and Environmental Design (LEED) standards, the academy incorporates efficient LED and fluorescent lighting, rigid insulation between the frame steel studs, double-pane Pella windows, occupancy sensors and set back controls, and an energy recovery ventilation (ERV) unit on the roof. Installation was carried out by Wolin Mechanical of Des Moines. Installation of the geothermal heat exchanger loop was completed by A-One Geothermal Inc. of Earlham, Iowa.

“As a family-owned and operated company, Vermeer incorporates a simple corporate philosophy focusing on people, product, profit, and ethical principles, our 4-P philosophy,” said VandenBosch. “The Yellow Iron Academy embodies our support for our team members’ families, and it was designed and built to a high standard of energy efficiency and sustainability for the education and safety of

their children.”

Information supplied by Bosch Thermotechnology and the Vermeer Corp. For more information, visit www.boschheatingandcooling.com or www.vermeer.com.

Publication date: 6/29/2015

Want more HVAC industry news and information? Join The NEWS on Facebook, Twitter, and LinkedIn today!