Fractional horsepower permanent split capacitor (PSC) fan motors are one of the most popular single-phase motors used in our industry. Troubleshooting and replacing these motors is a common task for many technicians. When these motors fail, it’s generally either something electrical or mechanical.

A common electrical failure is an open winding or open run capacitor. A common mechanical problem is tight or worn bearing(s). Problems with these motors may not always be easily recognized; the motor may seem to operate normally for a while and then shut down. It’s easy for a technician to overlook this problem, since the motors seem to be operating normally at first.

TROUBLESHOOTING STEPS

Here is a procedure that can be used to troubleshoot a PSC that’s not operating:

Step No. 1 — If the motor is not running, measure the voltage applied to it. It’s a best practice to measure the voltage directly at the motor leads and not at a location away from the motor. There may be a wiring break between your location and the motor that goes unnoticed. Normally, it should be within ±10 percent of the rated voltage as stated on the motor’s data plate. If there is no voltage applied to the motor or the voltage measures outside the ±10 percent tolerance, the problem is not within the motor but with the electrical circuit leading to the motor. If the correct voltage is applied, proceed to the next step.

Step No. 2 — Disconnect the voltage applied to the system. Verify the voltage has been disconnected with a voltmeter and then spin the fan blade attached to the motor’s shaft. The fan blade should spin freely. If it doesn’t, the bearing within the motor may be tight. If the motor has lubrication ports, try lubricating the motor with an appropriate oil type recommended by the manufacturer. This may resolve the problem. If not, replace the motor. If the motor does not have lubrication ports, then replace it. If the fan blade spins freely, proceed to the next step.

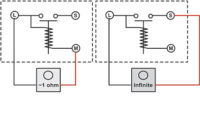

Step No. 3 — Disconnect all electrical wiring leading to the motor. With a standard ohmmeter, measure the resistance of the motor’s windings. There should be a measurable resistance across both the run and start windings. If it is a multiple-speed motor, measure each speed tap and verify there is a measurable resistance. If an infinite or zero resistance is measured on any of these measurements, the motor is electrically defective and needs to be replaced. If the windings are electrically OK, then proceed to the next step.

Step No. 4 — Remove the run capacitor from the circuit and check its capacitance. It should be within ±6 percent of the rating stated on the body of the capacitor. If an open or shorted capacitor is found, replace the capacitor and retest the motor. It should operate normally; if not, proceed to the next step.

Step No. 5 — If the motor is electrically OK, the problem is most likely mechanical. The motor’s bearings will need to be checked for wear. Remove the motor from the system and check the shaft for a loose bearing. This is done by holding the shaft and observing the movement between the shaft and the bearing. A horizontal movement of approximately 1/8 inch is normally OK. There should be no vertical movement. If any vertical movement is noticed, the motor needs to be replaced.

Following these steps should allow you to determine the problem with a nonoperational or intermediately operating PSC motor.

Publication date: 6/6/2016

Want more HVAC industry news and information? Join The NEWS on Facebook, Twitter, and LinkedIn today!