Homes, restaurants, bars, and businesses rely on clear, clean ice for many applications. Ice is considered a food source, and the water that makes the ice must be of good quality. Good quality water will produce a crystal-clear, hard piece of ice.

Ice hardness is a measure of the thermal cooling capacity (Btu) of the ice. It is measured as a percentage. Flake ice falls in the 75 percent hardness range while block ice falls in the 95-100 percent hardness range, depending on the water quality and how the ice is made. The higher the percentage of hardness, the more cooling ability or cooling capacity the piece of ice will have. This occurs because hard ice is denser than soft ice. Harder ice will last longer in a glass when cooling a drink or in a cooler chilling food.

Do not confuse ice hardness with water hardness. Water hardness has to do with the amount of minerals dissolved in the water. The more minerals dissolved in the water, the harder the water. Hard water reduces the ice hardness and its cooling capacity because of the higher mineral content in the ice. Figure 1 shows the difference between hard and soft ice. The ice sheet on the left is cloudy and soft; it contains a lot of minerals. The ice sheet on the right is clearer, denser, and will have a higher hardness percentage with more cooling capacity.

CLEAR, DECORATVE, SPHERICAL ICE

Ice is serious business, but that doesn’t mean people can’t have a little creative fun with it. A manufacturer in the U.S. has crafted an aluminum mold that creates a perfect 2.5-inch ice sphere to ensure the slowest melt, least dilution, and most efficient cooling of beverages. Custom logos can be laser-etched on the aluminum mold and new technology allows for custom logos or a company’s personal brand on the spherical ice ball itself. Venue operators, bartenders, consumers, and distributors are using this ice sphere as an essential accessory.

The aluminum molds come in bottle or cylinder shapes that are designed to complement the décor of prestigious restaurants, pubs, or personal bars. They are produced in three base colors — black, copper, and champagne — but can be special ordered in any pantone. The aluminum molds are sealed with a Food and Drug Administration (FDA) food-safe coating.

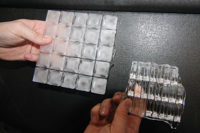

To make the spheres, water is placed in FDA-compliant, soft-silicon plastic ice block molds (Figure 2). Each mold yields an ice chunk that is placed into the aluminum mold (a bottom mold is shown in Figure 3) to produce the spherical ice ball (Figure 4). The 2.5-inch-diameter ice ball has been strategically designed to minimize the surface area of ice exposed to a beverage when compared to ice cubes and other ice piece configurations.

Regular tap water or bottled water can be used in this process, but using water treated with reverse-osmosis technology will produce the clearest ice ball. Remember, regular tap water varies in quality from one community to another, and that will affect the clarity of the ice ball.

A trick to producing very clear ice in the silicon ice block molds is to freeze the water slowly. Simply put the silicon ice block molds filled with the proper water in a small, unsealed portable cooler and place the cooler inside a larger freezer. This process will slow the freezing process and produce crystal-clear ice. Another method bar or restaurant owners may want to consider is to hire an ice sculptor to cut clear ice slugs into hexagon or square shapes to be placed in the aluminum mold. These shapes are the optimal choice for generating a crystal-clear spherical ice ball in the aluminum mold. This cost for the sculptor can in-part be offset by applying an upcharge to a drink.

SPHERICAL ICE BALL TECHNOLOGY

Here is the process for making a spherical ice ball. Once the ice is slowly frozen in the silicon ice block molds, remove the ice from the mold. With the aluminum mold sitting on a level surface, remove its top. Center the ice chunk from the silicon mold on to the base of the aluminum mold. Now, place the unit’s sleeve (top) over the base. Gravity and heat conductivity of the heavy aluminum top actually craft the spherical ice ball. The top aluminum mold will travel downward until it stops in the drip tray in approximately one minute. Remove the top. Use specially designed ice tongs to place the spherical ice in a glass.

In this process, the aluminum molds act as a heat-transfer medium to melt and shape the block of ice into a perfect sphere. How fast the ice melts depends on three factors and is governed by this equation:

Btu of heat transferred = (mass) x (specific heat) x (temperature difference)

Where:

• Btu = British thermal units of heat;

• Mass = Mass of the aluminum mold;

• Specific heat = Specific heat of aluminum; and

• Temperature difference = Temperature difference between the ice and the aluminum mold.

If the machine becomes cold to the touch, the spherical ice ball creation process will slow down. This happens because the temperature difference between the aluminum mold and the ice has become smaller. This temperature difference is the controlling factor in the speed of ice ball production. The temperature difference between the aluminum and the ice is the driving potential for heat transfer. In the equation above, the mass of the aluminum mold and the specific heat of aluminum are constants and are out of the control of the end user. So, for faster cycle times, place the machine under warm tap water after each use. This will warm the aluminum molds and cause a greater temperature difference between the aluminum and ice in the mold.

Figure 5 shows a kit that includes the top and bottom aluminum molds, ice tongs, and FDA-compliant silicon ice molds. For a demonstration, visit http://bit.ly/SpiritIceVice.

Publication date: 9/12/2016

Want more HVAC industry news and information? Join The NEWS on Facebook, Twitter, and LinkedIn today!