Arlington County, Virginia, a U.S. Department of Energy (DOE) Better Buildings Challenge partner, has already made significant progress cutting its energy use — it’s down 11 percent since 2009, putting the county well on its way to a goal of 20 percent reduction by 2022. But the county realized it could do more — and do it quicker — if it had a modular solution that could optimize energy usage among multiple building devices. That’s when John Morrill, Arlington County’s energy manager, discovered BEMOSS, or the Building Energy Management Open Source Software platform, an automated building control system.

For the past two years, a team of professors and graduate students at Virginia Tech, in close consultation with industry, have been developing BEMOSS through a DOE Building Technologies Office award. The goal: make it easier for smaller building owners to use low-cost building automation or energy management systems to cut their energy costs.

SMALL BUILDINGS ARE A HARD TO REACH MARKET

According to the DOE, commercial buildings consume approximately 20 percent of the total energy consumption in the United States — a percentage that’s about evenly split between large and small- or medium-sized buildings (under 100,000 square feet). Large-sized commercial buildings have used building management systems or building automation systems (BAS) for decades to improve occupant comfort and reduce energy costs. But small- and medium-sized commercial buildings — which not only consume half the sector’s energy usage, but also account for more than 95 percent of the commercial building stock — have lacked a cost-effective BAS solution and the savings that come with it.

This sector hasn’t adopted building automation for a number of reasons. Owners of these smaller buildings are often unaware of the amount of energy wasted by their buildings, nor are they aware of the amount of savings that a BAS can provide. Unfortunately, most building automation systems are custom-designed for individual buildings and the cost of tailoring software and acquiring hardware components is beyond the reach of most small- and medium-sized building owners. In addition, the building owner is not always the building tenant and does not pay the utility bill, thus there is limited incentive to invest in a BAS to increase the building’s energy efficiency.

BREAKING DOWN BARRIERS: COST AND INTEROPERABILITY

Before owners and operators of small- and medium-sized buildings begin adopting BAS on a wider scale, the systems need to become much more interoperable, scalable, and easy to deploy by using open architectures, being plug-and-play, and providing local or remote monitoring. With only a few exceptions, the fundamental building blocks necessary to develop such cost-effective controls solutions exist. However, many systems currently use proprietary architectures, and building owners and controls designers must purchase all devices and controllers from a single vendor instead of being able to choose the optimal products, controls, and services from different vendors to best meet their needs.

The Virginia Tech solution — BEMOSS — is seeking to address these long-standing barriers preventing widespread deployment. First, BEMOSS is designed as a turnkey solution to reduce installation and maintenance costs with the goal of ultimately reducing the price point by two orders of magnitude. In addition, BEMOSS is designed as a scalable and broadly interoperable solution with seamless integration of HVAC, lighting, and plug load equipment and controllers from different manufacturers, offering plug-and-play functionality for the many system configurations found in smaller commercial architectures.

In March, Virginia Tech released BEMOSS version 2.0, which features cybersecurity enhancements, a more efficient database architecture, and an automatic identification of the model number and capabilities of device controllers within a building. The new version also enables interoperability across multiple vendors and equipment by supporting prevalent communication technologies and protocols, getting closer to the end goal of true plug-and-play. Virginia Tech used DOE’s open-source, hardware-agnostic software execution platform, VOLTTRON, to host the BEMOSS solution.

FIELD TESTS DEMONSTRATE ENERGY SAVINGS

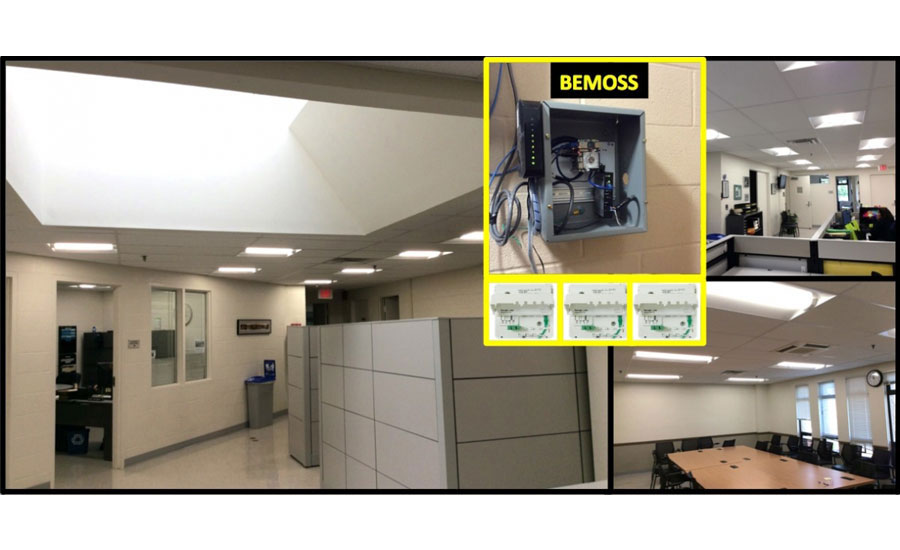

With the latest release, BEMOSS has entered its third and final development phase of its DOE award, during which it is field testing in three Virginia small- and medium-sized commercial buildings in the city of Alexandria, the town of Blacksburg, and Arlington County. As part of this testing, Virginia Tech is conducting real-time on-site measurements to estimate electricity savings potential in buildings with BEMOSS deployed, evaluate the platform’s robustness in the field, and demonstrate its fault detection capabilities. Based on preliminary data collection and analysis, the energy savings offered by BEMOSS is estimated to be at least 10 percent for HVAC loads and 15 percent for lighting loads.

“We have been very pleased with the deployment and use of the BEMOSS control technology,” said Morrill. “[BEMOSS] has been easy to use, reliable, and has been producing energy and cost savings from the first day of installation.”

MEETING THE NEED

The BEMOSS system is showing it can provide small-sized commercial building owners access to flexible, cost-effective building energy management that can streamline building operations and optimize energy usage. Furthermore, the greater interconnection between building systems and a centralized control structure in BEMOSS-equipped buildings will help facilitate demand response, providing potentially additional savings and better integration with the electric power grid. Additionally, as an open source solution, BEMOSS can be further developed and penetrate the market through outside users who download the code and software to develop applications that target their own challenges and gain entry into new markets.

Finally, and most importantly, energy managers like John Morrill will have exactly what they are looking for — an easy, plug-and-play solution that works with the equipment they have and saves them money on their utility bills.

Publication date: 10/10/2016

Want more HVAC industry news and information? Join The NEWS on Facebook, Twitter, and LinkedIn today!