1. Can I run a hot water zone off an existing steam boiler without a heat exchanger?

Yes, but there is a limit to how much radiation your steam boiler can support.

Manufacturers list two capacity outputs on every steam boiler: the Department of Energy (DOE) capacity, aka the boiler’s gross output, and the boiler’s net capacity. Gross output is about 20 percent higher than net capacity and includes capacity to pick up the system when you tum it on as well as the load of keeping the piping network warm. Net capacity is the energy available to beat radiation and keep the house warm.

Once the system has warmed up, the boiler has this extra 20 percent capacity. Its availability determines how much radiation can be supported for the hot water zone. You could run the zone in a priority condition if the load is greater than the pick-up factor, but this means no heat in the steam system while the hot water zone operates.

2. What keeps the water “up” in the piping and radiation?

The air around us has weight and presses down on everything it touches. This atmospheric pressure pushes down on the water in the steam boiler, forcing it up into the radiation.

The atmospheric pressure at sea level is 14.7 pounds per square inch, decreasing as you travel higher. One pound of pressure per square inch can lift water 2.31 feet. So, in theory, the atmosphere can support water to about 34 feet (14.7 x 2.31), but the practical limit is closer to 30 feet.

Because atmospheric pressure forces the water in a steam system up, you should never use vents in the condensate zones off the boiler. If you do, as soon as a vent opens, the condensate will fall into the boiler and flood it.

3. What happens if I add the hot water zone loads to the size of my replacement steam boiler?

Oversizing your steam boiler will “shove” too much steam into a system designed for a lesser load. That leads to all kinds of problems — water hammer, surging water lines, and uneven heating. Don’t do it.

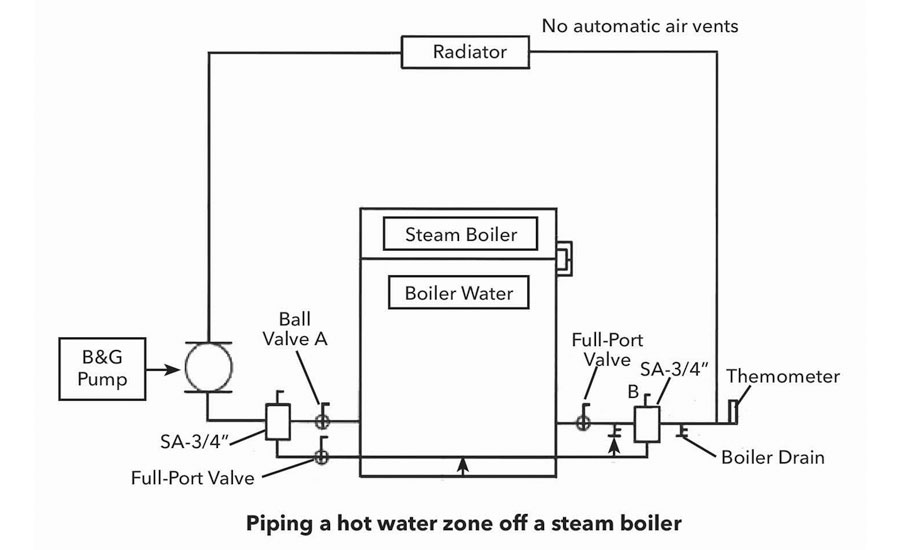

4. How should I pipe the hot water zone off the steam boiler?

Locate the supply and return connections below the boiler’s water line (see the illustration above). Ideally, you should have a good cross-sectional flow through the boiler, so that the water doesn’t “short-circuit” through the boiler and not pick up enough Btu.

Locate the circulator on the supply side (below the water line), pumping away from the boiler and out to the radiation so that its pressure differential is added to the system, not subtracted. This helps prevent the water from flashing into steam and causing water hammer.

5. What else should I consider when piping the hot water zone off the boiler?

Be sure to pipe a bypass around the boiler to limit the temperature of the water that will circulate out to the radiation. When the boiler is producing steam, the water temperature is the same as the steam. At one psi of steam pressure, the water temperature is 216°F; at two psi, the temperature is 218°, and so on. The problem with water being this hot is that, when the circulator shuts off because the zone is satisfied, it’s likely that some of the water up in the zone will “flash” into steam. Remember, these systems don’t have pressure reducing valves, so the water at the top of the system is under no pressure. Since water can flash into steam at 212° at zero psi, whenever the circulator turns off, you can get “banging” in the hot water zone and a flooded steam boiler in the basement.

Reprinted with permission from Xylem’s SteamTeam, Volume 2, Issue 5, September 2015. For more information, visit http://unitedstates.xylemappliedwater.com.

Publication date: 11/21/2016

Want more HVAC industry news and information? Join The NEWS on Facebook, Twitter, and LinkedIn today!