A large percentage of compressor failures in low-temperature vapor-compression refrigeration system applications originate from overheating. Typical compressor capacity rating data is based on an industry standard of a 65°F return vapor temperature. While a 65° return vapor temperature may be satisfactory for high-temperature applications and, perhaps, some medium-temperature applications, unsatisfactorily high-discharge temperatures are virtually unavoidable on low-temperature applications. This is due, in large part, to the thermodynamic properties of the refrigerant.

Refrigeration oils have been highly refined in an effort to elevate the temperature at which chemical decomposition occurs, and experience has shown mineral oil decomposition begins when compressor internal temperatures reach 350°. Compressor manufacturers typically indicate that discharge gas temperatures are 50° to 75° higher at the discharge valve inside the compressor than out on the discharge line, 6-8 inches from the service valve. Therefore, dangerously high temperatures already exist inside the compressor when discharge line temperatures are well below 350°. This lubricant decomposition is accelerated by residual contaminants that are present in a typical system. Studies have shown the rate of chemical reaction doubles with every 18° temperature increase. For example, a chemical reaction that takes 10 years to complete at 100° will only take five years to complete at 118°. At 136°, it would be complete in two-and-a-half years.

However, mineral oils are vulnerable to losing the lubrication film necessary to prevent metal-to-metal contact between bearings and journals, or piston rings and cylinders, prior to the temperature at which decomposition begins. With mineral oil, this occurs approximately between 310° and 330°. When these compressors’ internal temperatures are reached, the probability of extreme piston and ring wear is imminent.

REFRIGERANT EVOLUTION

Hydrocarbons (HCs) and other natural refrigerants were employed in early vapor-compression refrigeration application designs. Many of these were highly flammable, toxic, or both. Developments in the late 1920s and into the early 1930s delivered a small group of organic compounds — the chlorofluoocarbons (CFCs) and hydrochlorofluorocarbons (HCFCs) for use as refrigerants — and CFCs and HCFCs proliferated into all types of refrigeration and comfort cooling applications. This continued unimpeded for nearly 50 years. These refrigerants typically were selected for various applications in large part based on their favorable thermodynamic properties relative to the system type in which they were to be applied. That is, CFC-12 was predominantly used for medium-temperature refrigeration, CFC-502 was predominantly used for low-temperature refrigeration, and HCFC-22 was principally used for comfort cooling.

However, in the late 1970s, environmental concerns with CFCs and HCFCs arose owing to scientific theories linking these organic compounds to concerns of global ozone depletion. Chorine-containing CFCs were quickly targeted for elimination from use as refrigerants. HCFCs, which contained a smaller amount of chlorine, also were earmarked for eventual elimination.

To speed the move away from CFCs, HCFC-22 initially was more widely specified for new and retrofit use in both medium- and low-temperature refrigeration systems. Additionally, a number of zeotropic blend refrigerants containing predominantly HCFC-22 appeared on the scene and were deployed as interim replacements for CFC compounds.

Prior to this, HCFC-22 had already been in wide use in systems with higher saturated suction temperatures for comfort cooling. However, the extended use of HCFC-22 into medium- and low-temperature refrigeration applications was not without its challenges.

Because of the thermodynamic properties of HCFC-22 — which result in decreased vapor density and increased compression ratios — lower saturated suction temperatures clearly would result in unsatisfactorily high discharge temperatures and the associated oil decomposition and lubrication problems without further intervention.

Consequently, as HCFC-22 was considered to replace CFC refrigerants in medium- and low-temperature refrigeration applications, a need was quickly recognized to address these inherent high-discharge temperatures to ensure a reasonable life expectancy of compressors.

Compound compression techniques were implemented to combat high compression ratios, and liquid injection methods, including the use of desuperheating thermostatic expansion valves (TEVs) to address high discharge temperatures, were adopted for new equipment installations.

APPLYING THE TREV

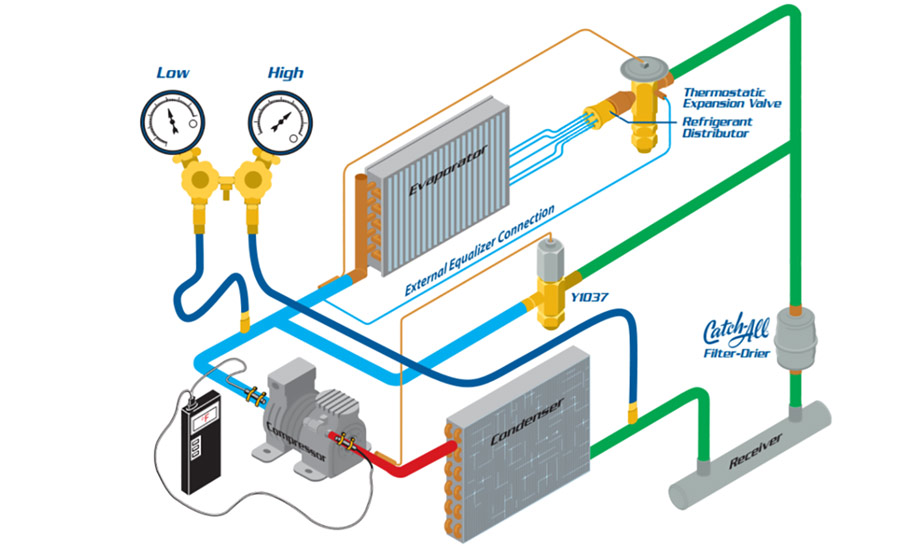

One cost-effective method of preventing destructive superheat at the compressor for these HCFC-22 medium- and low-temperature systems was the introduction of the temperature responsive expansion valve (TREV) (see Figure 1). Using liquid from the high side of the system, the TREV injects saturated refrigerant into the suction line ahead of the compressor in direct response to the temperature of the discharge line.

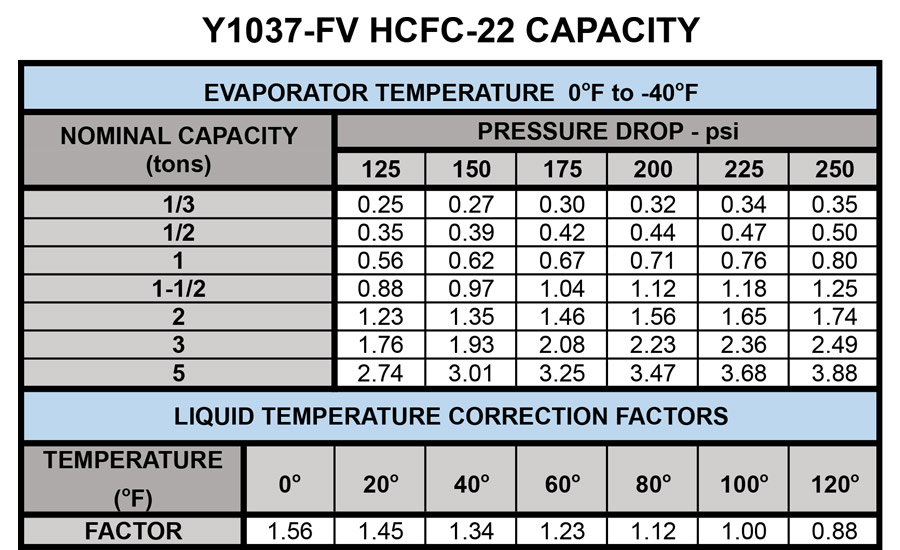

This valve does not have an equalizer line and is not influenced by system pressure as a desuperheating TEV is. A sensing bulb is placed on the compressor discharge line 6 inches from the compressor discharge outlet connection. The valve responds directly to a rise in discharge gas temperature. Temperature settings are available from 115° through 275°. A bellows assembly similar to that employed in a direct-acting pressure regulating valve is used. The valve power element is charged with a hydraulic fluid that expands as its temperature increases. Multiple capacity sizes are offered for HCFC-22 to a nominal capacity maximum of 5 ton (see Table 1).

A liquid supply line to the TREV is connected to a high side location that will provide vapor-free liquid to the valve inlet. The TREV is designed to feed saturated refrigerant directly into the compressor suction line 12-18 inches before the compressor (see Figure 2). Other locations are possible, and the suitability of these locations should be determined by proper testing and evaluation. Good thermal contact between the sensing bulb and discharge line is essential, and insulating the bulb with a high-temperature insulation, such as fiberglass or its equivalent, is recommended.

From the onset of the more extensive use of HCFC-22 to replace CFCs in medium- and low-temperature systems, it was recognized that eventually it, too, would be eliminated from use. Chemical companies conducted ongoing research and development to offer suitable long-term substitute refrigerant compounds, and hydrofluorocarbon (HFC) refrigerants with zero ozone-depletion potential were developed. HFC-404A and -507 quickly became the commonly specified refrigerants for medium- and low-temperature refrigeration systems.

HFC-404A and -507 were considered “cooler” refrigerants by comparison to HCFC-22 regarding discharge temperature. However, even with these HFC refrigerants, destructive superheat caused by higher condensing temperatures has been experienced periodically in some geographical areas of the U.S. during operation in peak summer conditions, specifically in low-temperature applications. Liquid injection has continued to be employed but with less frequency.

DESIGN ADVANCES

As compressor designs evolved, an inherent reduction in compressor temperatures was achieved on specific applications. These design improvements fall into several areas, such as reduced contact between the motor and compressor housing, improved motor designs, reduced volumetric clearances due to improved machining tolerances, and minimization of heat transfer between the high- and low-pressure areas of the compressor.

Meanwhile, the international scientific community initiated concern over global warming. Concerns about greenhouse gases enter the worldwide consciousness, and chemical compounds were evaluated for their global warming potential (GWP). This led to the introduction of HFC refrigerants with comparable thermodynamic properties but lower GWPs than HFC-404A and -507 for medium- and low-temperature applications. HFC blend refrigerants designated as HFC-407A and -407F were developed. Compared to HFC-404A, (GWP = 3,922), HFC-407A (GWP = 2,107) offers a reduction of just less than 50 percent and HFC-407F (GWP = 1,824) provides a reduction of just more than 50 percent in GWP. Of these two refrigerants, HFC-407F exceeds in capacity and efficiency. However, discharge temperatures for HFC-407F are greater by comparison than that of HFC-404A and -507.

Once again, a means of reducing discharge temperatures to maintain quality of lubricant and extended compressor life was desired. Liquid injection using the TREV, while having been developed originally to address high discharge temperatures associated with HCFC-22 use on low-temperature applications, has proven to be a suitable device for application with HFC-407F as well. Because it is a temperature-responsive valve, which is not impacted by system pressures, this liquid injection valve may be satisfactorily applied in HFC-407F applications to eliminate potential lubricant decomposition due to high-discharge temperature operation. And, it can be field-applied as needed to existing systems as they are converted from a previously specified refrigerant to HFC-407F.

TREVs AND THE FUTURE

The chemical companies continue to pursue safe, low-GWP refrigerants while maintaining suitable performance characteristics to replace those that have gone before. The most recently introduced low-GWP refrigerant alternatives are hydrofluoroolefin (HFO) compounds. Pure HFO refrigerants have GWP numbers below 1, meaning they are of less concern regarding global warming than even carbon dioxide. They are safety-classified as A2L by ASHRAE (nontoxic but mildly flammable); however, it was discovered that by blending HFOs with HFCs, the mild flammability is mitigated, resulting in an ASHRAE classification of A1 (nontoxic and nonflammable) although with an increase in the GWP number.

These HFO/HFC blend refrigerants are entering the marketplace. They are considered as chemically safe, similarly performing refrigerant alternatives with a markedly lower GWP than HFC-404A and -507. HFO/HFC-448A and HFO/HFC-449A are proving to be very suitable alternatives to continue the transition away from HCFC-22. Additionally, they are also considered useful substitutes for the higher-GWP HFC-404A and -507.

In the evaluation of HFO/HFC-448A and HFO/HFC-449A, it has been recognized that, once again, dangerously high discharge temperatures and the associated probability of lubricant decomposition may be unavoidable, particularly on low-temperature systems. Thankfully, the TREV continues to be available as an effective component that may be deployed to allow systems to operate at acceptable compressor discharge temperatures with these new blended refrigerant compounds.

The TREV, as a true temperature responsive valve that is not influenced by system pressures, continues to be an effective problem-solving tool for new alternative refrigerants that may experience potentially destructive high compressor discharge temperatures. It will also more than likely continue in this role as the refrigerant landscape continues to unfold.

Publication date: 9/4/2017

Want more HVAC industry news and information? Join The NEWS on Facebook, Twitter, and LinkedIn today!