What’s one more regulation among friends?

This one in particular requires HVAC manufacturers to comply with the U.S. Department of Energy’s (DOE’s) energy conservation standards for residential furnace fans starting July 3, 2019.

The DOE published a final rule (79 FR 38129) prescribing the standards for residential furnace fans July 3, 2014, which stated the prescribed energy conservation standards for these products would result in significant conservation of energy and are technologically feasible and economically justified. The DOE predicts the new standard for furnace fans will save approximately 3.99 quads of energy, reduce carbon pollution by up to 34 million metric ton (equivalent to the annual electricity use of 4.7 million homes), and save Americans more than $9 billion in home electricity bills through 2030. The standards account for power consumption in heating, cooling, and constant circulation modes.

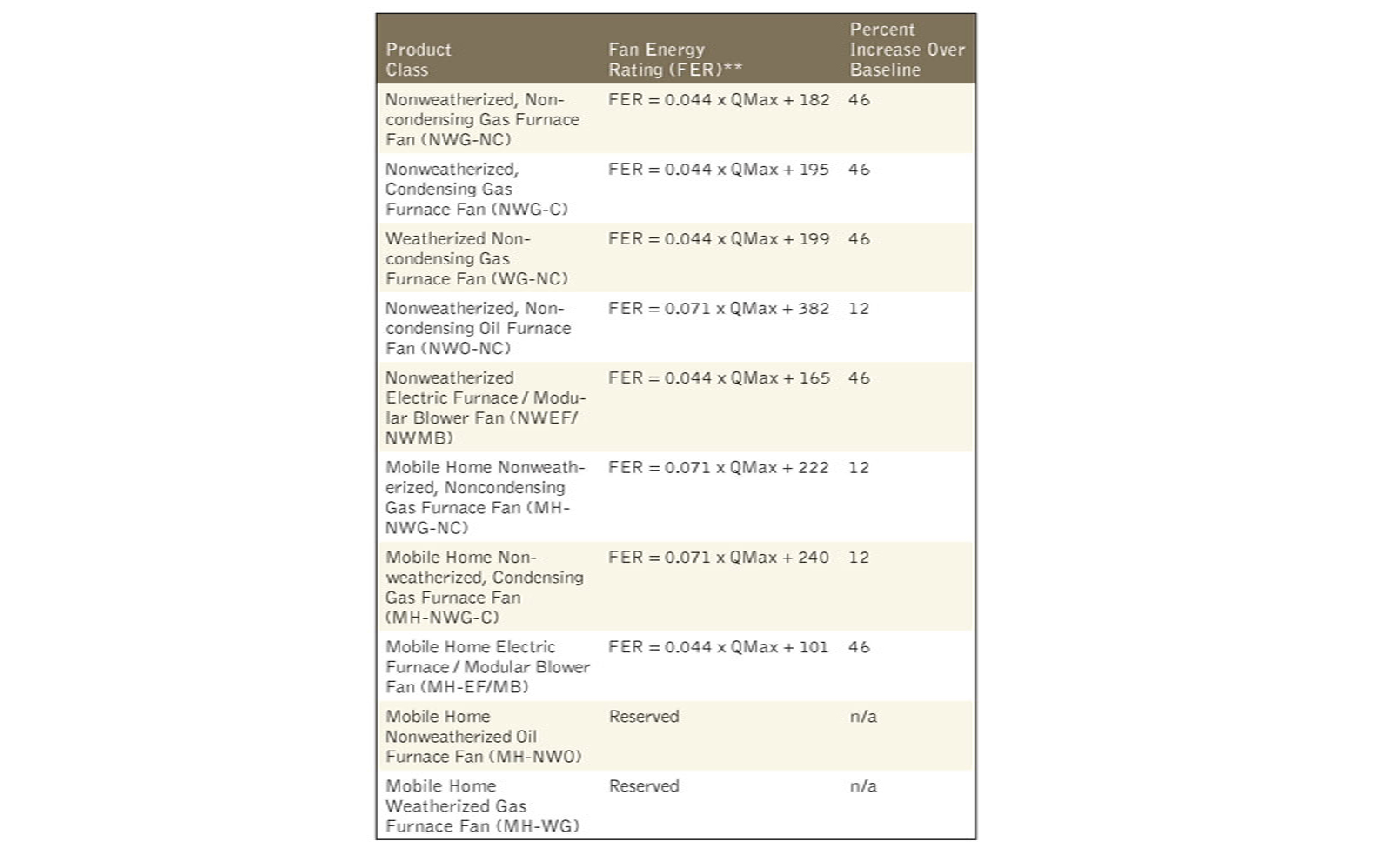

Rich Bardgett, market manager, Nidec Corp., said the fan energy rating (FER) standard is essentially designed to regulate the efficiency of the fan in gas-fired furnaces, but that really means the motor. To date, the vast majority of furnaces have been equipped with standard induction motors, which operate at about 60-65 percent efficiency. He said the standard is likely to create an industrywide shift to electronically commutated motors (ECMs).

“They’re targeting fan efficiency, but really, the only lever the furnace manufacturers have to pull in that regard is the motor,” Bardgett said.

Bardgett said ECMs feature two modes of operation: constant airflow within the system or constant torque of the motor.

The constant airflow systems tend to be more high-end, so what the regulation likely means for most furnaces is a shift from induction motors to constant-torque ECMs. What remains to be seen is if the energy savings justify the significantly higher upfront cost of the ECM.

“It’s kind of a paradigm shift for both the furnace and motor industries,” Bardgett told The NEWS. “As a motor manufacturer, this is a positive change due to the shift to newer technology. However, it will add cost to the furnace, and there is a balance we need to maintain between technology and incremental cost since we are relying on the equipment manufacturers to be successful.”

Bardgett said the effects of the change on HVAC contractors might be a mixed bag. On the downside, it could hurt new equipment sales when customers are faced with a repair vs. replace scenario brought on by the failure of a major component. Higher prices on new equipment may lead homeowners to decide to repair their old unit with an induction motor and live with it a little longer rather than pay for a more expensive system with

an ECM.

“Going from an induction motor to an ECM is an added cost to a homeowner,” Bardgett said. “Up until now we’ve seen strong sales on the equipment side rather than the component side. It will be interesting to see what happens when it flips, and there’s that added incremental cost in the unit.”

On the plus side, however, the new regulation might eventually make life easier for contractors and technicians by helping them optimize their motor inventory.

“With ECMs, a single pre-programmed motor will have the capability to replace a wide array of motors with the same horsepower ratings,” Bardgett said. “Furthermore, if greater motor optimization is required, a technician also will be able to program the motor with the proper operational settings. Technicians will save time by making less trips to a wholesaler because they’ll be more likely to have the correct motor on their truck.”

LEVERAGING ECMs WILL BE KEY

As Regal’s customers evaluate the various options to comply with these upcoming regulations, leveraging the application of ECMs across product platforms will be key, according to Deep Dey, director of marketing, FER, Regal Beloit America Inc.

“In order for original equipment manufacturers to meet these regulations, the efficiency afforded by ECMs will help them with compliance,” he said.

Dey said homeowners looking to buy furnaces after July 3, 2019, will benefit from the energy savings that ECM-equipped furnaces will provide. He added that as the furnace mix shifts from induction motors to all ECMs in the upcoming years, contractors will need to be aware they will encounter and work with these motors more often.

“Contractors and technicians need to be well-trained on ECMs and have an overall knowledge of this new market,” he said.

Dey pointed out Regal Beloit has a 20-year history with ECMs and said the company has engineered a motor designed to fill the gap that will be left as induction motors are increasingly phased out.

“The new motor is an entry-level product that will drive the lowest cost of ownership for customers,” he said. “We also equipped the motor with IoT [Internet of Things] features, such as near-field

communication and BLAK BOX® motor technology that will address the challenges faced by contractors and technicians tasked with installing, programming, and troubleshooting ECMs.”

Boima Morray, vice president of marketing, American region, Danfoss Drives, said the FER regulations are important to both manufacturers and contractors because the efficiency rating of the fan will likely dictate the most appropriate motor and motor controller for the application. He added that contractors should always be aware of what’s inside the units they’re selling to their customers.

“When any new standard comes to life, we go through vendor approval,” he said. “Any vendor who does not meet that standard is precluded from providing products into the market. So, it gives contractors peace of mind that if it’s a Danfoss product, the standard will be met.

“It’s important for contractors to know that a particular solution they’d like to apply will be in compliance,” he continued.

‘SIGNIFICANT’ SAVINGS

Joanna Mauer, technical advocacy manager, Appliance Standard Awareness Project, said the 2019 FER standards will provide significant savings for consumers by cutting the electricity consumption of furnace fans by approximately 50 percent.

“Although hidden to most consumers, furnace fans are a significant component of residential electricity consumption,” Mauer said. “DOE estimates that typical furnace fans use about 1,000 kilowatt-hours per year or almost 10 percent of the total electricity use of an average home in the United States.”

Mauer agreed that manufacturers will likely meet the standards by transitioning from less-efficient permanent split capacitor (PSC) motors to more-efficient X13 and ECM motors, which are already being used in some products.

“X13 and ECM motors are not just more efficient but can also improve comfort by doing a better job of providing sufficient airflow,” Mauer said. “The efficiency of furnace fans can also be improved by providing multistage controls on the furnace.

“With a multistage or modulating furnace, the fan runs for a longer time at a reduced speed, which saves energy since power decreases with the cube of the speed,” she continued. “Multistage and modulating furnaces also improve comfort by reducing temperature swings.”

Mauer added that the DOE estimates the new standards will save an average consumer about $340 to $500 over the lifetime of a furnace fan even after accounting for the increased upfront cost.

INDUSTRY CONCERNS

At the Air-Conditioning, Heating & Refrigeration Institute (AHRI), the focus is on practical matters, such as the FER test procedure, as the July 2019 effective date approaches.

“The general consensus is that the industry finds the current test procedure lacks clarity,” said Frank Stanonik, chief technical advisor, AHRI. “This is making it difficult for manufacturers to establish FER ratings for their equipment.”

AHRI has an ongoing Request for Guidance on the FER test procedure, and Stanonik said the institute is trying to determine if there are alternatives to the current test procedure.

“The industry also feels that the DOE should not be regulating products at the component level and that doing so restricts the variety of products available to consumers,” he added.

Publicaiton date: 1/29/2018

Want more HVAC industry news and information? Join The NEWS on Facebook, Twitter, and LinkedIn today!