Think of the benefits to students of training in an HVACR lab filled with equipment trainers that mirror industry trends and the needs of today’s HVACR employers. Now, imagine the experience they’d get by not only learning on the trainers, but building them themselves.

That’s exactly the type of real-world experience that students at the College of DuPage (COD) HVACR program are getting. Recently, students built two state-of-the-art cooler trainers, working from the ground up.

The cooler trainers are the latest addition to the college’s HVACR lab, built entirely by students over the last few years as part of COD’s Central Plant Project, located at its Glen Ellyn, Illinois, campus. The lab also includes a state-of-the-art hydronic boiler trainer, cutting-edge electrical and building automation trainers, high-pressure steam boiler trainers, and chilled water trainers — including the chillers’ latest addition: walk-in/refrigeration trainers, a project that will continue be expanded on in the future.

College of DuPage is the largest public community college in the state of Illinois, serving about 26,000 students each term. Students in the HVACR program can pursue certificates as a service technician, stationary operator, or energy analyzer, as well as associate’s degrees like contractor, service technician, and facility maintenance mechanic.

“The Central Plant Project … there’s so many parts to it,” Bob Clark, HVACR program coordinator at COD, said. “It’s 13,500 square feet, so it’s like 100-something by 100-something [feet in size]. We have air handlers, different loads … we have full connectivity, building automation … We have probably one of the most bad-ass hydronic labs in the country.”

BUILDING THE LAB

Work on the HVACR lab started in the winter of 2014.

“We wanted a lab that was built by students so that they could demonstrate their skill sets to the HVACR industry,” said Clark. “Anyone can pay for a lab; not everyone can build their own.”

The walk-in refrigerators are the latest addition to the lab’s chiller section. Students built the coolers completely from scratch, beginning with an installation class that put together the frames, followed by the mechanical and electrical components, which were added as part of a commercial refrigeration class.

Since the school is based around semesters, additions to the lab were built more or less in “chunks” by multiple classes of student technicians. To date, five classes have worked on the cooler project, plus three hydronic classes installing the snowmelt system inside the freezers.

“It takes about seven weeks to get them going in a 16-week course, so they’ve got eight solid weeks to work on it,” said Clark. “They get to see the craftsmanship of the students who worked on it before them — it’s about getting that pipe straight and level. We have multiple classes developing them multiple ways. This next semester, we are starting to build our supermarket rack system with them. It’s really a conglomeration: multiple students, multiple classes, over multiple years.”

The two 8-by-24-foot cooler units feature closed-cell insulation. Each 24-foot section contains three freezers and has interior doors designed to change load characteristics, modelling real-life situations and creating variable training options.

The students aren’t professionals yet — but their work sure is, according to Clark.

“We limit our class size to 16 people, so they’re in the lab and they’re working,” he said. “The students did everything, and that’s the difference between us and the other schools: We don’t use contractors to build our equipment. We have people fly in from North Carolina … to tour the facility, so they can pay their contractors to build it like our students do. I’m not trying to brag, but it’s the best lab in the country.”

AN INVESTMENT

The cooler project, like much of the HVACR lab, was funded through Perkins Grants adding up to more than $100,000 total.

“If you compared it to the millions that it would cost to pay a contractor, it is an incredible investment,” said Clark. “More so, it is an investment in the students and their living portfolio for the industry.”

That investment is mirrored by the college’s staff, who donated their time in the planning stages of the project.

“Like everything, it is never finished,” Chris Lexow, an HVACR instructor at COD, said. “There is always a new development. For example, the hydronics class is building a false load glycol snowmelt system inside of the coolers. This is a great example of using one aspect of the lab to support another. We teach technology, and that means that you have to always evolve with it. The more the system is built up, the more ideas we have to improve on the original design and ways to utilize it.”

Working with the coolers, students can experience both rack and individual systems, similar to those used in supermarkets and restaurants. They can learn wiring and mechanical control strategies. Plus, the coolers are strong enough to support students walking on the top, to further recreate real-world circumstances.

In terms of hands-on experience, constructing the refrigeration units was a unique and invaluable opportunity, said Lexow.

“This was a fantastic project to work on with my class,” he said. “The best part about it was seeing the students come together and learn to work as a team to complete the task at hand.”

Mike Pagliuco, a recent graduate of the program, echoed the sentiment.

“Working on the coolers was a great experience,” he said. “It gave me real-world experience in a controlled setting, so any mistakes you might make won’t cost thousands of dollars. In the end, I felt completely comfortable that when I threw the switch, it was going to work — and it did.”

Pagliuco earned his associate’s degree in facility maintenance this spring. For him, COD was a chance to forge a new professional path.

“I had spent the last several years in the workforce as a prep cook working in corporate kitchens, and I was unsatisfied with where my career was going,” he said.

Then, he happened to meet an HVAC building engineer and realized that HVAC was a field he could really enjoy.

“I came into this program with no knowledge in any of the trades,” Pagliuco said. “COD’s HVACR program gives you the hands-on knowledge to succeed in any of the many HVACR fields out there, right off the bat. I didn’t even know what being an HVAC technician entailed or how many different routes there were. I enrolled, thinking I wanted to work on residential equipment. Now, I work for a building automation company that controls skyscrapers.”

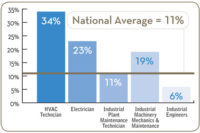

That kind of job placement is typical of COD graduates, said Clark.

“Our students, they get jobs right out of college, and we’re not even accredited,” he said. “They leap straight from our program and go to Trane Commercial, they go to Johnson Controls, they operate major buildings in downtown Chicago. Everyone else says their numbers are going down; our numbers are going up.”

Clark chalks up the program’s success to tight partnerships between education and industry.

“The industry buy-in is unbelievable, what they’ve done to help us in terms of product,” he said. “All of our supply houses, manufacturers, and partners helped. It could have been the price of copper, the price of the refrigerators, the Sporlan valves donated, or the electrical raceways that carry all of the power and control.”

Those partners are so willing to help because they can see their contribution being immediately re-invested in the field, he continued.

“Manufacturers, contractors, and supply houses want to help programs, but they also want to see results,” Clark said. “They do not need to see their donations sitting on a shelf for six years. The community college’s job is to be the crossroad where the new workforce meets our industry. In regards to our program, I take that meeting very seriously because I want all students to have the opportunity, if they are willing to work for it, to be successful in the workforce. That only happens if you deliver real technicians to the industry.”

In the end, programs like COD’s lab end up as a win for all parties involved.

“Our students, our contractors, and our partnerships all benefit from the relationship that they have with the school,” Clark said. “We are all in this together.”

Publication date: 10/29/2018

Want more HVAC industry news and information? Join The NEWS on Facebook, Twitter, and LinkedIn today!