The regulatory landscape for refrigerants used in chillers has become more complicated, thanks to the court decision that declared the Environmental Protection Agency (EPA) is not authorized to regulate HFC refrigerants under the Clean Air Act. As a result, EPA’s Significant New Alternatives Policy (SNAP) Rule 21, which required the use of lower GWP refrigerants in chillers as of 2024, remained in legal limbo until last month, when the U.S. Circuit Court of Appeals for the D.C. Circuit issued a decision to vacate that rule.

Some states are not happy with this decision and are proposing their own phasedown schedules of HFCs. For example, California has adopted SNAP Rule 21, so as of Jan. 1, 2024, the state will prohibit the use of specifically listed HFCs in chillers. While most manufacturers still offer chillers that use R-134a and R-410A, they are beginning to utilize alternative refrigerants that will comply with these new laws. However, the search continues for solutions that not only have a low GWP but are efficient, safe, cost-effective, and nonflammable. A difficult task, to be sure.

NOT READY FOR PRIME TIME

California’s aggressive approach to reducing HFCs may be problematic, as manufacturers contend that viable alternatives are not yet available to take the place of refrigerants commonly used in most chillers. Indeed, California’s approach will likely result in an early transition away from R-410A, presenting severe issues, since many of the new low-GWP alternatives to R-410A on the market are flammable, said Brian Smith, director of global marketing - Chiller Solutions, Johnson Controls Inc.

“R-410A alternatives present the greatest challenge to the HVAC industry, given the fact that many of the new low-GWP refrigerant replacements, such as R-454B, R-32, and R-290 (propane), are flammable,” he said. “While some of these flammable alternatives can be attractive from an energy efficiency and low-GWP standpoint, we must proceed with caution.”

More time is needed for safety standards and building codes to be revised and adopted, and for manufacturers, distributors, and service technicians to build the infrastructure and knowledge base that will allow for the safe transition to flammable refrigerants, said Smith.

He noted that Johnson Controls supports, encourages, and funds research of new refrigerant alternatives that are safe, sustainable, readily available, economically viable, and efficient. That takes time, though, which is why he is concerned that recent product announcements could give consumers the impression that the HVAC industry is ready to move to low-GWP refrigerants immediately, which may not be the case.

That’s why it is important to keep in mind that new refrigerants are not necessarily better or worse than current refrigerants, said Gaurang Pandya, president of Global Equipment, Carrier Commercial HVAC, adding that some may be better for the environment, but not all — just as some may be more efficient, but not all.

“Just switching to a low-GWP refrigerant does not guarantee that a unit will be better environmentally,” he said. “Each case needs to be analyzed to make the most sensible choice that factors in environmental impacts from a life cycle perspective.”

In addition, many of the new low-GWP alternatives are classified as A2L refrigerants (mildly flammable), and as noted above, current standards and codes need to be changed in order for chiller manufacturers to be able to offer equipment that utilizes these solutions.

“Changing building codes is a lengthy process that begins with changes to the safety standards, application, and equipment standards used by the building code writing organizations; updates and approval of the building codes; and eventual adoption by the states,” said Pandya. “All building codes are controlled at a state level, and in some cases, by cities or counties. So, not only do the national building codes need to be updated, but they need to be adopted as well. Standards need to be completed and submitted by 2019 for new codes to be available in 2024 and then need to be adopted by states, which can take several years.”

Click chart to expand

or

Click here to view/download the chart as a PDF

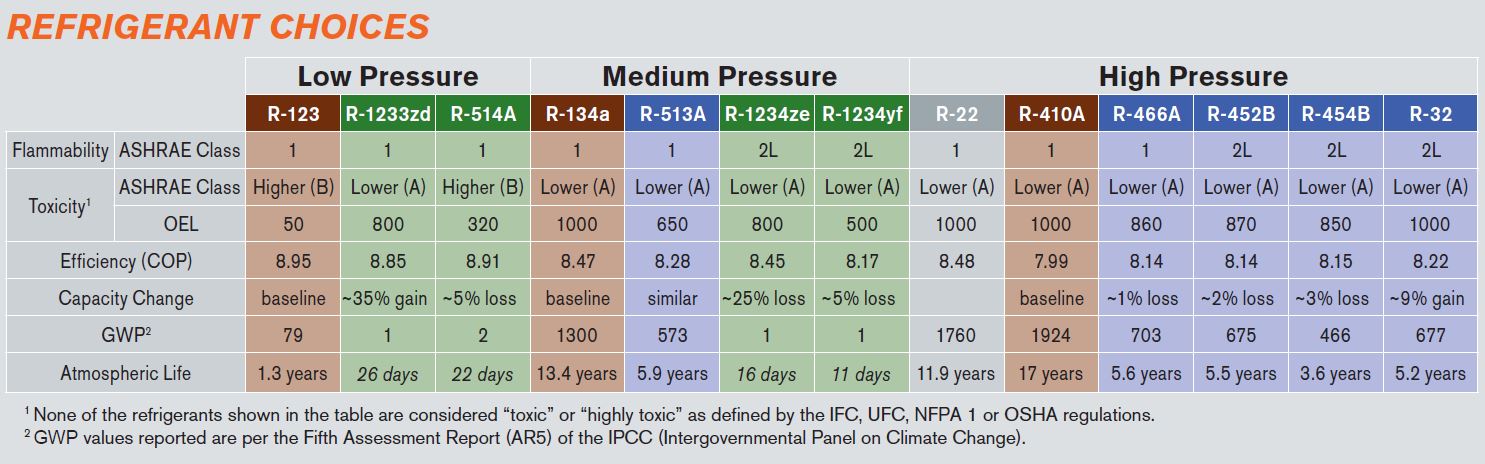

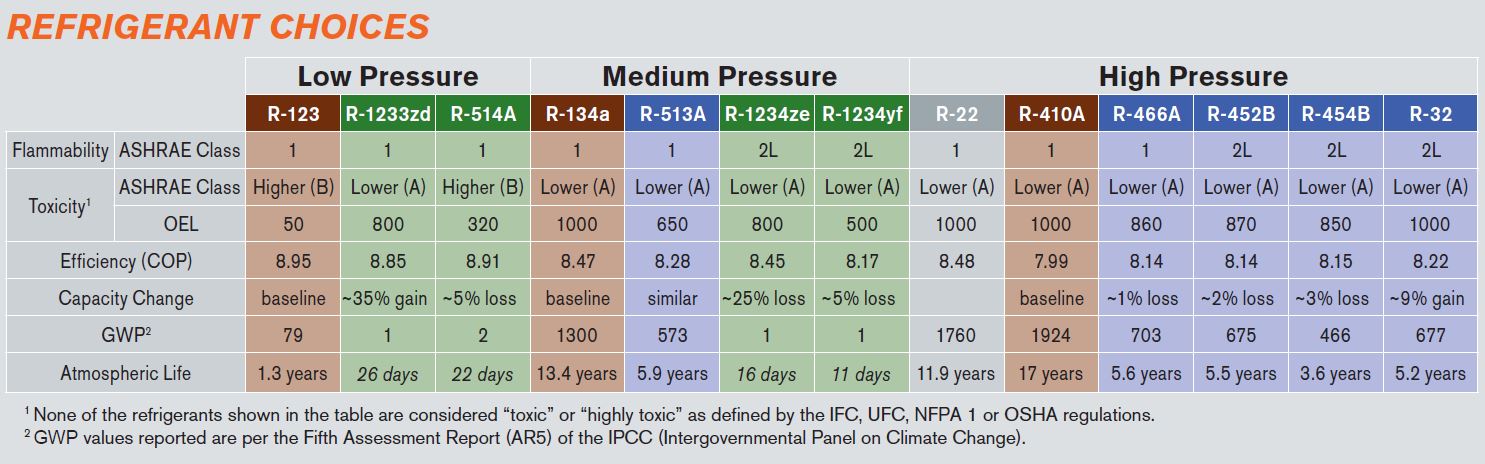

REFRIGERANT CHOICES: This table compares various properties of both current and next-generation refrigerants. The efficiencies and capacity changes shown are based on the theoretical properties of the refrigerant alone, with all design variables held constant for objective comparison. INFO COURTESY OF TRANE

POSSIBLE ALTERNATIVES

Daikin Applied currently offers R-410A and R-134a in its chiller products, as these positive-pressure A1 refrigerants provide the efficiency, ability for oil-free operation, serviceability, and compact footprint that customers demand, said William Dietrich, product general manager of chillers, Daikin Applied Americas. That said, he believes that future alternatives for R-410A and R-134a will likely include R-32, R-454B, R-1234ze(E), and R-1233zd(E).

“For R-410A, initial studies indicate that there could be efficiency gains with R-32 or R-454B and that the charge quantity may be reduced as well,” he said. “This will require changes in compressor and equipment designs for full optimization, so it will be an expensive undertaking for the industry. Given that they are both low-toxicity, mildly flammable refrigerants, building code issues must be addressed to safely apply them.”

R-1234ze(E) is the best alternative for R-134a in ultralow-GWP (<10) applications, said Dietrich, as it offers similar efficiency. However, it requires compressor and chiller design changes to obtain the same capacity that could be achieved with R-134a, and again, because it is an A2L refrigerant, code changes will be required for proper application.

R-1233zd(E), which is a low-pressure fluid that is similar in performance to R-11, has the advantage of slightly higher pressures, so customers will end up with American Society of Mechanical Engineers (ASME)-designed and constructed pressure vessels, noted Dietrich.

“This is one of the few ultralow-GWP fluids that falls into the A1 category, so it will be the refrigerant of choice for low-pressure centrifugal chiller applications,” he said. “Another option is R-514A, which is a low-pressure refrigerant that offers similar efficiency and lower capacity when compared to R-123. However, it is a higher-toxicity (B1) refrigerant and will likely not be widely used. I think R-1233zd(E) is a much safer long-term choice for customers.”

The bottom line is that most new-generation refrigerants have trade-offs between performance, GWP, toxicity, and flammability, said Smith.

“Lower-GWP refrigerants in medium-pressure applications typically provide less efficient operation and/or introduce flammability issues,” he said. “This potential loss in efficiency is critical, because the greatest impact HVAC systems have on global warming and greenhouse gas emissions is from energy consumption, not from the refrigerant fluid in the system.”

Higher pressure alternatives can offer lower GWP and improved energy efficiency, Smith added, but this comes at the expense of flammability.

“Only in low-pressure applications do we currently find low-GWP, nonflammable options with improved efficiency,” he said. “However, there is higher first cost for both equipment and refrigerant.”

NEXT-GEN REFRIGERANTS: The evolution of refrigerants from the past to the next generation. INFO COURTESY OF TRANE

LOW-GWP OPTIONS

While there are no perfect refrigerants that are efficient, nonflammable, and nontoxic, said Pandya, Carrier is finding R-1233zd(E) to be the best option for its low-pressure centrifugal chillers.

“This refrigerant was chosen because of its ultralow GWP, efficiency, A1 safety rating (nontoxic and nonflammable), and availability,” he said. “In addition, Carrier will offer R-513A as an option on some of its R-134a-based units.”

Internationally, Carrier offers R-1234ze(E), an A2L, very low-GWP refrigerant, for its customers in Europe, where modified standards and building codes are already implemented. It cannot be offered in the U.S. until building codes allow for its use, said Pandya, but there is considerable research underway to develop information for codes and standards for A2L refrigerants, as well as to evaluate new refrigerant options.

For Carrier chillers that are designed to use either R-134a or R-410A, the company does not recommend retrofitting these units to utilize a new refrigerant.

Trane continuously evaluates a range of refrigerant technologies, looking for the best refrigerants for each application based on a balance of safety (toxicity, flammability, asphyxiation, and physical hazards), environmental impacts (lowest greenhouse gas emissions), and total cost of ownership (energy efficiency of the entire system), said Mike Thompson, refrigerant strategy leader, Trane. The company currently has three centrifugal lines in the U.S. that are part of the Ingersoll Rand EcoWise portfolio of products that uses low-GWP refrigerants.

“Our CenTraVac chillers use two low-pressure fluids: R-1233zd(E) and R-514A,” he said. “We also have a third line in our compact, magnetic-bearing Agility Chiller™ that uses R-513A or R-134a. R-513A offers minimal impact on capacity, zero ODP, and a reduction in GWP of up to 55 percent over that of R-134a.”

Thompson added that because some low-GWP refrigerants reduce the delivered output tonnage per nominal and physical size of compressor, larger compressors will offset the reduced output tonnage.

“High-speed magnetic bearing technology allows compressors to deliver more tonnage per cubic feet of size, which can help with change from one refrigerant to another,” he said. “Consequently, solutions with lower GWP like R-513A are likely to remain viable longer term.”

Johnson Controls’ YORK® YZ magnetic bearing centrifugal chiller is fully optimized with ultralow-GWP R-1233zd(E), meaning it combines improved operating efficiency at full load and off-design conditions with new chiller technologies in order to offset the higher cost of the new refrigerant. In addition, all York R-134a screw and centrifugal chiller lines are qualified for use with low-GWP refrigerant R-513A.

“R-513A is a combination of R-1234yf and R-134a, which have both been commercially available for a long time,” said Smith. “Although R-514A is a newer refrigerant currently being offered as a retrofit solution for R-123 chillers, both R-123 and R-514A are classified within the higher-toxicity category by ASHRAE, and this classification may limit its use in some applications.”

NATURALS NOT LIKELY IN U.S.

As for natural refrigerants, such as ammonia, CO2, or hydrocarbons, most manufacturers believe these are not suitable for use in chillers in the U.S.

“Ammonia is flammable, toxic, and has a high initial cost due to its incompatibility with copper and the building code limitations on restricting its use,” said Pandya. “The use of ammonia may increase in areas where it makes economic, environmental, and safety sense. For example, in controlled industrial sites in sparsely populated areas or isolated machine rooms that could be engineered to have the right mitigation and so forth.”

He added that CO2, while a great choice for refrigeration, is not efficient for comfort cooling applications, and it is also a very high-pressure refrigerant that requires significant system design changes.

“Its use will probably grow as a secondary loop refrigerant, when used in conjunction with another refrigerant to do the actual cooling,” said Pandya. “Other natural refrigerants like hydrocarbons are limited to small-charge systems by the current safety standards and building codes due to their very high flammability, and therefore will probably only be used in small appliances with charges less than 114 to 150 grams.”

Although in Europe, Johnson Controls currently offers an air-cooled chiller that uses propane as the refrigerant, but it is for very specific applications and only available to customers with the ability to handle a highly flammable fluid in their air conditioning systems, said Smith. Both propane and ammonia are used in some industrial applications that incorporate strict building and safety guidelines for these types of fluids.

While the industry continues to wait and see about federal and state regulations regarding the future use of HFCs, Smith added that it is important to remember that any new regulations currently being negotiated do not limit the availability of HFCs to service existing installed equipment.

“Current regulations are focusing on the reduction of conventional HFC use and the move to lower-GWP alternative solutions in new equipment,” he said. “R-134a and R-410A are not banned, are still widely used and available, and are the best options for chiller equipment today.”

Publication date: 5/6/2019

Want more HVAC industry news and information? Join The NEWS on Facebook, Twitter, and LinkedIn today!

REFRIGERANT CHOICES: This table compares various properties of both current and next-generation refrigerants. The efficiencies and capacity changes shown are based on the theoretical properties of the refrigerant alone, with all design variables held constant for objective comparison. INFO COURTESY OF TRANE