Welcome to the Refrigeration Showcase, which includes comprehensive coverage of the different types of equipment and controls commonly encountered in the field. From ice machines to reach-ins to controls and components, the Showcase is designed to educate contractors about the new commercial and industrial refrigeration products available, so they can help their customers make the right choice for their application.

Figuring out which refrigeration equipment or controls package will work best for an application can be challenging. Larger supermarkets, cold storage facilities, and restaurant chains often have in-house personnel who make this decision, but they still value the input from their local contractors who service their equipment. Smaller regional stores and restaurants typically do not have these in-house resources, so contractors usually have a larger role in recommending equipment solutions.

For both these situations, the Refrigeration Showcase will help contractors learn which ice machine, refrigeration unit, component, and/or control will best serve the needs of their customers. Manufacturers have provided detailed information for the Showcase that includes the benefits end users will experience by using their products, as well as how they have made their equipment easier for contractors to install and service.

For food retailers, their priority is making sure that any new equipment keeps their products safe, fresh, and cold — reliably and efficiently. The products highlighted in the Refrigeration Showcase are designed to do just that.

Back to gallery

Back to gallery

Food retailers and cold storage operators are most concerned with making sure their refrigeration equipment can reliably keep products safe, fresh, and cold. If that equipment can also save energy, that’s an added bonus. These issues are important to contractors as well, but they would also like the refrigeration equipment to be easy to install and service. Addressing all these concerns can be a challenge for manufacturers, but the equipment and components described below are designed to appeal to both end users and the people who work on them in the field.

Product: The AHT Vento Green MC AIR Series was engineered for versatility in virtually any supermarket application, both new construction or retrofit, offering exceptional flexibility.

Details: There are currently two available size configurations — 2.5 meters (8 feet) and 3.75 meters (12 feet). Each includes either two or three hermetically sealed scroll compressor circuits that each contain 5.22 ounces of R-290 (propane), an HFC-free, low-GWP refrigerant. The temperature range of this multideck unit is between +30°F and +44°F.

Features: Extremely versatile for open use or equipped with glass doors for front of store placement, offering convenient grab-n-go packaged foods and ready-to-go meals. Intelligent plug-and-socket links for all installation and shelf unit connections ensure quick and easy setup. Shelf modules can be easily added, removed, or repositioned at any time. Compressor management via Pack-Controller (dynamic load adjustment) improves energy efficiency, with only one to two compressors operating at a single time once unit reaches setpoint. Low start-up current and immediate cooling within hours, along with energy-efficient fans.

Benefits: This revolutionary series of plug-in multidecks for meat and dairy products provides flexibility, requires minimal installation, and boasts sustainability in operation and investment. The innovative concept of fully integrated refrigeration technology reduces system complexity and installation work to a minimum.

Service, maintenance, and installation: Completely flexible, connectible, plug-in shelf units, from individual placement up to entire store systems. Total freedom of layout in the store as well as simple repositioning and system expansion, even in existing stores. Fast setup thanks to Plug and Chill technology. Due to reduced installation time required, program implementation and roll-outs of grab-n-go and other initiatives can be concurrently expanded. Due to the refrigeration system being hermetically sealed during line production, the leakage rate is zero, meaning no refrigerant ever needs to be added. Minimal maintenance due to factory quality and highly efficient industrialized production. No substantial installation work is required. Optional pump for condensate removal can be easily integrated when floor drains are not available in existing buildings.

Warranty information: One-year comprehensive parts and labor warranty is standard.

Product: The Azanechiller 2.0 is an outdoor packaged refrigeration system that operates with a low ammonia charge and is well suited for a variety of new construction or retrofit applications, including industrial process cooling, HVAC, ice rink and data center cooling, wineries, breweries, and more.

Details: The Azanechiller 2.0 operates using a low ammonia charge in the range of 1.5 pounds/TR [ton of refrigeration] and is available in capacities from 40 TR up to 340 TR for a single package. The high-temperature range of chillers is designed to chill a secondary water loop to 44°F, while the medium-temperature range is designed to chill a secondary glycol loop to 18°F.

Features: Each reciprocating compressor is driven by a variable-frequency drive (VFD), resulting in exceptional part-load efficiency. Most of the range is available with either single or dual compressor options. The Azanechiller 2.0 is equipped with an air-cooled condenser with electronically commutated (EC) fans, stainless tubes, and epoxy coated aluminum fins. The flooded combined plate-and-shell evaporator/suction separator is extremely robust and designed with a close approach with negligible superheat, leading to an efficient and reliable evaporator. The UL508a control panel includes smart controls and industrial-quality components.

Benefits: A reliable and efficient chiller, the Azanechiller 2.0 offers efficiency, minimized maintenance, and long-lasting industrial quality components.

Service, maintenance, and installation: This industrial-quality product features fully welded baseframe steel and fully welded piping. The minimum life expectancy is 20 to 25 years. The smart PLC includes predictive maintenance functionality and helps extend compressor run time between services. The air-cooled condenser uses no water and is easy to clean. Oil return is automatic, eliminating the need for frequent manual oil returns. Routine maintenance is required several times a year to keep the system in optimal condition. Installation is easy, as the package is fully assembled, pressure tested, and electrically tested in the factory. The oil circuit and compressor head cooling glycol circuits will be charged upon arrival. Once the unit is set in place, the water and electrical connections need to be made. Once complete, the units are charged with ammonia, commissioned, and started up.

Warranty information: Standard warranty of 12 months after commissioning or 18 months after the unit is ready for shipment from the factory, whichever is sooner.

Details: The Vertex evaporative condenser is suitable for retrofit applications and for new construction. It is available in 10- and 12-foot widths and a variety of lengths to match typical footprints in the industry.

Features: Large access door eliminates confined space limitations in many applications. Internal walkway allows for easy serviceability while staying dry. Direct-drive electronically commutated (EC) fan system with low-sound, high-efficiency components is entirely serviceable from the interior of the unit. Optional belt-drive fan system with unsurpassed access to bearings allows for ease of maintenance. Redundancy in fans, motors, and pumps for uninterrupted operation. Reduced operating weight to allow higher capacity for retrofit applications on existing support steel

Benefits: The Vertex condenser offers maximum uptime with easy and safe accessibility and low total cost of ownership. It uses a direct-drive EC fan system, which maximizes reliability and uptime, and reduces operating costs while requiring no regular maintenance. In addition, users can save energy in winter months due to the EC fan system’s high efficiencies at low speeds. Redundancy inherent in the overall design of the unit – including fans, motors, and pumps – delivers uninterrupted operation to end users. The condenser requires less water than competing products and delivers 10 percent lower energy usage as well.

Service, maintenance, and installation: A large access door, sturdy step, and safety handle provide safe entry and exit. Vertex condensers feature an internal walkway to keep maintenance personnel safely dry while inspecting the basin, strainer, and drive components, while the compact, sloped water basin ensures easy cleaning and improved hygiene. Inspection of all nozzles is fast and easy with the optional pre-assembled platforms at an ergonomic working height. The condenser reduces installation costs by 30 percent, in part by aligning the upper section to the lower section in less than 15 minutes per cell, due to the industrial-grade rigidity of the unit. Single-point wiring simplifies field installation and saves time, as does the lack of variable-frequency drive (VFD) or vibration switch. Water volume is reduced by up to 30 percent, saving on water and chemical costs, which helps reduce the operating weight by an average of 16 percent. No regular maintenance is required for the direct-drive EC fan system.

Warranty information: Standard equipment warranty is for a period of one year from the date of startup or 18 months from the date of shipment, whichever ends first. In addition, there is a five-year mechanical drive warranty covering the fans, fan shafts, bearings, sheaves, supports, and NEMA fan motors. A five-year leak-free basin warranty is standard on units with basins upgraded to stainless steel or the Tri-Armor® corrosion protection system. Extended warranties are also available through local BAC sales representatives.

Details: This 8-foot by 20-foot refrigeration unit is designed for the harshest environments at sea or land.

Features: Designed for storage of deep frozen, frozen, chilled, or heated products with a temperature range from -30° to +86°F.

Benefits: Forklift pockets on each side for easy transport. Double cargo door and optional 3-foot by 7-foot service door with strip curtains and heavy-duty hardware. LED lights are prewired and ready to go. This new, heavy-duty, Magnum, dual-temperature refrigeration unit uses R-404A. It is all electric, features quiet operation, and has no need to refuel or hook-up the refrigeration, just bring power to it (60-foot cord included).

Service, maintenance, and installation: White steel exterior panels with stainless steel lined interior walls and ceiling. T-rail reinforced aluminum flooring (pallet jack and forklift rated), so it is ready for any heavy loads and traffic. Full all-weather roof for outdoor or indoor use for air-and water-tight storage. Minimal maintenance required. 3 phase 230/460 V.

Warranty information: Standard 60-day warranty on new units, 30 days on used.

Product: HEOSBox is a high-efficiency, water-cooled, condensing unit used in a microdistributed system architecture.

Details: HEOSBox was designed for use with retail refrigerated cases, dual-temperature display cases, and walk-ins. The unit can be used in both new installations, where a manufacture would assemble the unit with the case in a factory, and for retrofits, where a contractor would utilize the technology to convert an existing centralized system to a microdistributed system.

Features: HEOSBox features advanced PLC-based controls for case functions, BLDC horizontal rotary compressors, BLDC motor drives, and electronic expansion valves. The combination of these components promotes a fully modulating system that is able to quickly change based on environmental and case conditions. HEOSBox is available with R-448A and R-449A early in 2021 Carel will be releasing the first CO2-based condensing unit for similar applications. The unit has been designed for both medium- and low-temperature applications.

Benefits: This plug-and-play style solution employs a guided wizard and simplified configuration to reduce the learning curve and ensure an easier installation and initial configuration. Contractors can leverage features such as remote access, read/write capabilities, reporting, and alarm notifications for improving their service level for the end use customer. The microdistributed architecture allows users to eliminate a significant amount of mechanical room space. Format flexibility is also a major benefit. In most installations, the units can be moved by simply disconnecting the water lines and repositioning the cases. This grants significant flexibility and labor cost reductions when updating store formats.

Service, maintenance, and installation: Several mechanical and software-based features support simple installation and service. For example, hoisting brackets, which can be used with a mini-crane for simplified placement and mounting. Labeled removable connectors are located on the exterior of the unit to reduce the complexity and the amount of time needed to wire high- and low-voltage components. Mechanical connections are also located on the exterior of the box to remove the potential for brazing errors and component damage. Technicians can utilize the Carel Boss supervisory system for loading unit configurations, synoptic views, and store layouts for simplified and controlled mass loading of multiple units at once. For those installations not utilizing a supervisory system, Carel has created a simplified guided wizard that allows a technician to input basic parameters (setpoint temperature, defrost type/termination, etc.) to commission the unit. The unit requires no routine maintenance, as proactive and predictive alarms alert contractors and end users to potential issues that could lead to component failures. The hydronic system may require regular preventive maintenance, depending on the type of heat rejection equipment selected for the project.

Warranty information: A warranty of 24 months from the date of manufacture on this product. Extended warranty may be negotiated for volume purchases.

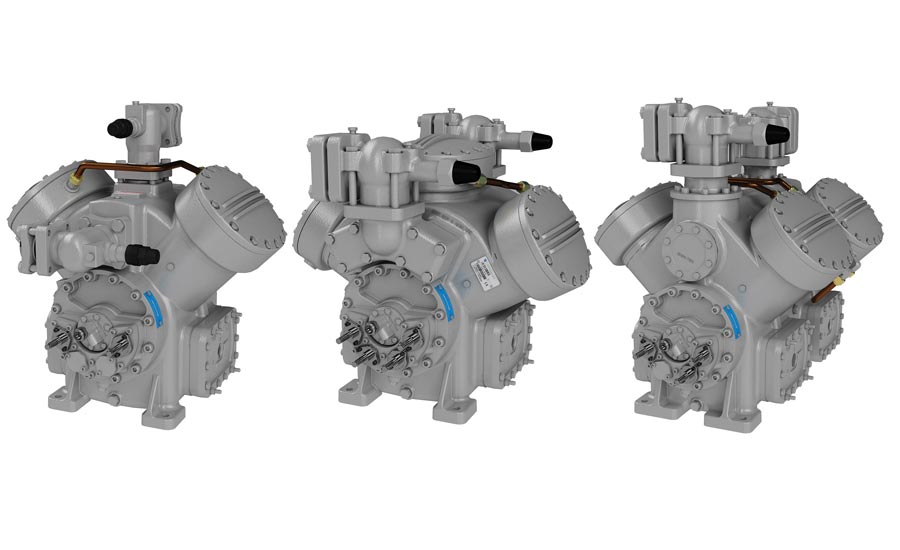

Details: The 5H41, 5H61, and 5H81 compressor models are nominally 25, 40, and 50 HP, and are well-suited for many low-temperature booster and medium applications, particularly those in food retail, ice making, and light industrial businesses. The new 5H compressors were designed specifically to operate safely under the unique characteristics of ammonia. Carlyle will expand its release of the 5H ammonia product to 75 HP later this year.

Features: The 5H ammonia compressors are available with integrated electric solenoid unloading or dedicated variable speed models. All compressors come standard from the factory with integrated oil pressure protection. Water-cooled cylinder heads are factory-installed options.

Benefits: Integrated oil pressure protection and electric solenoid unloading greatly simplify the installation and control of these compressors. Variable-speed models offer continuous unloading for an even better capability to match the compressor capacity to system load.

Service, maintenance, and installation: Lower mass flow rates mean smaller piping designs that may reduce installation costs.

Warranty information: Standard 36-month warranty on all 5H compressors.

Details: CO2 transcritical refrigeration system replaces existing R-22 installations. CO2 condensing units are available in 10 tons of refrigeration (TR) per fan. A four-fan unit can provide 40 TR of heat rejection and can operate between -40°F and +60°F. Semi-hermetic reciprocating compressors and electronically commutated motor (ECM) fans on evaporating and condensing side.

Features: Harmless CO2 refrigerant reduces or eliminates risk of facing environmental or health and safety restrictions in the future. Equipment outlasts conventional installations.

Benefits: Less energy usage since the compressor is not used for a portion of the year. Fewer moving parts since there is no need for a pump for free cooling. Eliminates the need for refrigerant fees and reduces service costs.

Service, maintenance, and installation: The design pressure of the system is 1,740 psi, so the piping between the gas cooler and indoor unit must be high-pressure. Carnot recommends stainless steel tubing that can be bent and welded through orbital welding.

Warranty information: One-year warranty on parts and labor. Can add four-year warranty on fans and compressor for additional cost.

Product: The Century BLU Series condensing unit line is a newly released product for the Comdustrial™ refrigeration market. The BLU is designed for energy efficiency in walk-in coolers and freezers, wine storage rooms, flower storage, smaller docks, controlled atmosphere rooms, keg coolers, produce storage, and various process rooms. The BLU unit is ideal for new construction as well as replacement and retrofit applications.

Details: The BLU is a small-footprint, vertical-air discharge condensing unit designed with energy-efficient scroll compressors or semi-hermetic compressors. Horsepower ranges from 3 to 10 HP for low-temperature applications and from 2 to 9 HP for medium- to high-temperature applications. The current design refrigerants are R-404A, R-507A, R-448A, R-449A, R-134A, R-407A, R-407C, and R-407F.

Features: The BLU line is designed with electronically commutated (EC) Vari-Speed fan motor assemblies with integral low sound. The profiled fan blades are mounted inside a full bell mouth housing with discharge diffusers. Each unit has a NEMA 3R electrical enclosure with control panel door-hold open brackets for service. All contactors utilized are IEC rated. Each base has forklift pockets for ease of offloading and setting the units in place in the field. The vertical airflow design provides service access on three sides, which allows tremendous flexibility for installation and service.

Benefits: Compact unit design with factory-mounted options typically only available on large horsepower condensing units, such as replaceable core liquid line filter drier and sight glass, replaceable core suction filter, suction accumulator, heated and insulated receiver, adjustable flood control components, control panel large enough for circuit breakers and contactors, and electronic controls for condenser fan and defrost. Acrylic-coated finstock, copper fin, and coated condenser coil options are also available.

Service, maintenance, and installation: The NEMA 3R electrical enclosure is large enough to house and access the electrical components easily. The door-hold open feature allows the door to be pinned in the open positions so it won’t close on the technician during servicing. The electrical diagrams are easily visible inside the enclosure door along with a QR code that can be used to help access product data and instructional service videos. The cabinet is open on three sides under the condenser assembly to allow ease of access to refrigeration components for service and maintenance. The condenser fan motor has quick-connect M12 plugs for the fan motor electrical connections, should service be required.

Warranty information: Standard warranty covers 12 months after installation with the option to purchase a four-year extended compressor warranty.

Product: The S1G305 electronically commutated (EC) fan assembly is specifically designed as an air mover for use in walk-in cooler and freezer applications. It can be used in new OEM designs, or it is easily used as a field replacement to upgrade from an AC to an EC motor when replacing motors during service calls.

Details: This is a complete fan assembly that includes an EC motor, 10-inch diameter blade, and mounting struts assembled as a complete unit right out of the box. It is compatible with all types of refrigerant systems and can be used in applications with temperature ranges from -40°C to +40°C. This 10-inch fan diameter is a very common size that is used in many walk-in cooler and freezer applications.

Features: The S1G305 fan assembly has a wide voltage range input of 100 to 240 vac and operates at either 50 or 60 Hz input. The blade is mounted and balanced and is programmed to provide the correct airflow direction, eliminating the chance of installing a blade backwards or having to match up motor rotation during a replacement job. The strut mounting is adaptable to the most popular OEM bolt patterns and is available in either a single-speed unit or as a 10-speed version to match air performance needs exactly.

Benefits: This fan assembly replaces the need for contractors to carry various motors of different voltages, rpm, and rotation, as well as different blade configurations. The fully assembled S1G305 fan assembly can replace many of those individual components that take up room in inventory or on a service truck. The EC motor offers higher efficiency compared to shaded pole or PSC motors that are commonly used in walk-in coolers and freezers. This results in the end user saving money whenever the fan is in operation.

Service, maintenance, and installation: Installation of the S1G305 fan assembly will typically be quicker than having to replace just a failed motor on a service call for a walk-in cooler or freezer. There is no need to remove and reuse the old blade or mounting struts that are usually difficult to remove, and there is less chance for installation error. A rotary switch on the back of the motor can be adjusted with a slotted screwdriver to set one of the 10 pre-programmed speeds to match the air performance needed in the application. The fan is outfitted with a 2-pin plug, making it truly plug-and-play. The fan assembly requires no periodic maintenance and uses ball bearings in the motor construction for a long and trouble-free life.

Warranty information: One-year standard warranty.

Product: The Copeland™ Digital Outdoor Refrigeration Unit, X-Line Series is ideal for multiplexing walk-in coolers, display cases, food preparation areas, reach-ins, and other common refrigeration equipment. It was designed with convenience store, small-format store, and restaurant operators in mind and can be utilized in both retrofit applications and new construction.

Details: These digital outdoor refrigeration units provide more precise, reliable refrigeration, longer-lasting equipment, and lower energy bills in medium-temperature applications. With 20 to 100 percent modulation now available, the Digital X-Line unit offers multiplexing capabilities for a variety of foodservice and food retail establishments. It combines Copeland scroll digital compressor technology, large-capacity condenser coils, variable-speed fan motor control, and smart controls to meet today’s challenging refrigeration requirements. The digital units range in horsepower from 3 to 6 HP (at 100 percent capacity) and are qualified for use with R-404A, R-407A, R-407C, R-448A, and R-449A refrigerants. The units feature advanced onboard protection and diagnostic controls in a quiet, compact enclosure.

Features: Due to its digital compression technology, fewer condensing units are needed for numerous refrigeration loads, which results in fewer line runs, lower refrigerant charges, and faster installation. For example, one Digital X-Line unit can run three walk-in coolers instead of three separate condensing units in a one-to-one setup. Electronic controls allow quick and easy set-up with only three setpoints required to commission an X-Line unit: 1) setting the time clock; 2) selecting the refrigerant; and 3) setting the suction pressure. The controller is also preprogrammed with numerous alarm and error codes for easy troubleshooting, avoids nuisance service calls, and allows technicians to diagnose issues quickly and accurately. On-board diagnostics provide connectivity to facility management control systems (including Emerson’s Site Supervisor suite of control products) to alert technicians of faults and key performance indicators (KPIs).

Benefits: The Digital X-Line unit provides the HVACR industry with a simple and affordable solution for multiplexing applications, precise temperature control, and energy-efficient solutions. Contractors benefit from having fewer condensing units to install and maintain due to multiplexing capabilities, fewer line runs, and lower refrigerant charges. End users appreciate an affordable solution that reduces start-up capital costs. The Digital X-Line is engineered for operators seeking to lower energy bills and helps them manage food quality and safety.

Service, maintenance, and installation: The Digital X-Line unit’s slim profile, lightweight design, and wall-mount option give technicians flexibility regarding where to install the units, even in locations with significant space constraints. Due to its lightweight design, cranes and heavy equipment are not typically needed to install a unit. The coil coating applied on the aluminum fin material provides a very low micron finish, which allows for dust and dirt to easily be washed away. Built-in diagnostics and protection allow operators to take action to minimize product loss from equipment downtime. Errors can be quickly communicated to service technicians, so that operators and service technicians can make changes to protect the system against faults that might otherwise cause a compressor failure. No special maintenance required beyond a standard condensing unit.

Warranty information: Standard one-year warranty.

Product: DOE-compliant Low-Profile Unit Coolers, manufactured under the brands Bohn, Larkin, Climate Control, and Chandler, are installed in an extensive range of applications, such as food service, food retail, supermarket, and industrial cooling and cold storage to improve product integrity and preserve shelf life of perishable products. Redesigned to meet new DOE 2020 Annual Walk-in Energy Factor (AWEF) minimum efficiency standards, these coolers are ideal for new construction projects as well as retrofit applications.

Details: The Low-Profile Unit Cooler is ideal for medium- and low-temperature walk-in cooler and freezer applications and works with R-404A/R-507A, R-448A/R-449A, R-407A/R-407F, and R-407C refrigerants. These units come standard with two-speed electronically commutated motors (ECMs) on air defrost models and single-speed ECMs on electric defrost and hot gas defrost models. Each unit includes internally enhanced tubing and fin design for higher efficiency, and the coil heater slots have been enlarged for easier installation and replacement. A variety of optional factory-mounted components are available, including the Quick Response Controller™, Beacon II™ Controller, or intelliGen™ Refrigeration Controller, which uses smart technology to quickly diagnose issues, increase product integrity, and reduce energy costs through optimizing defrosts.

Features: Composite, molded access panels, constructed of NSF and UL sanitation-rated material, ensure the unit’s durable, lightweight exterior is damage-resistant from drops, dents, and dings. The hinged, removable access panels provide easy access to the unit’s electrical and refrigeration elements. New fan guards optimize the unit’s air circulation and comply with the new UL60335 standards. Their quick-removal assembly, combined with easy-service motor mounts, make servicing and replacement quick and efficient. The hinged drain pan with extended heaters improves access to service and clean the drain pan and coil. Heaters provide uniform defrost capabilities and additional heat for end components.

Benefits: With the advancements in technology and the release of new refrigeration industry regulations, the Low-Profile Unit Cooler product design has evolved to give technicians features that improve ease of installation and servicing. This results in reducing downtime for end-use customers while potentially allowing more time to service more accounts. Low-Profile Unit Coolers are designed for maximum capacity while occupying a minimum amount of space inside a walk-in cooler or freezer. The motor technology is up to 75 percent efficient as compared to shaded pole motors, which are only 15 to 30 percent efficient, and PSC motors at approximately 45 percent efficiency.

Service, maintenance, and installation: Enhanced installation and serviceability features include easy access to the unit’s electrical and refrigeration elements; new low-profile cabinet design features hinged; and removable access panels. Re-engineered fan guards’ quick-removal assembly, combined with easy-service motor mounts, makes servicing and replacement quick and efficient. The hinged drain pan improves access to service and clean the drain pan and coil. Heaters provide uniform defrost capabilities and additional heat for end components.

Warranty information: Manufacturer did not specify.

Product: The Kooljet KJ Cube packaged refrigeration systems are designed and built under a plug-and-play concept. These units are easy to install, maintain, and relocate and are widely used in farms, agro-industrial, food processing, and commercial applications worldwide, including blast freezing, cold storage and freezing rooms, greenhouse coolers, controlled atmosphere environments, wine and beer processing, hydrocooling, and more. New construction and retrofit projects are common for these highly customizable units.

Details: Kooljet Cubes, skidmount, and rooftop forced air packaged units are built with scroll compressors that mainly use R-404A. Environmentally friendly prototype CO2 units are under development and soon to be launched. Units range from 3 to 60 HP, but being modular, Kooljet can easily customize applications where larger capacities are needed. Units are able to deliver air temperature ranging from -76°F to 55°F. Units feature standard remote, electronic, two-stage temperature control, but controls can be customized to communicate with the most sophisticated systems in the market.

Features: Packaged units are plug-and-play, so they are ready to be installed once they arrive at the final destination. Units are built with a free cooling option, which allows the automatic entrance of fresh air from the ambient when the setpoint temperature of the room is lower of that than the ambient temperature, while maintaining room temperatures and humidity levels without using the refrigeration circuits. This feature is unique of Kooljet and allows savings of several thousand dollars a year, depending on the application. Kooljet packaged systems are always designed and built with fully independent dual refrigeration circuits. This provides staging capability during non-peak operational stages, as well as reliability. Should one of the circuits fail, the other will remain fully operational, bringing the total capacity to half instead of having a shutdown.

Benefits: Units are easy to relocate to a new building or structure without losing immediate operational capabilities. Packaged units are plug-and-play and modular. The automatic free-cooling technology allows big savings for the end user. During colder weather months, the refrigeration system will be bypassed while keeping temperature and humidity levels at the desired setpoint.

Service, maintenance, and installation: Very easy installation. When units are delivered, they just need to be properly supported into the structure and hooked up to the power supply. All components are commercially available, and the service access points are easy to reach for maintenance or preventive work. An annual inspection and cleaning of coils is recommended.

Warranty information: One-year warranty with extended service contracts (depending on the region).

Product: Embraco FMF compressors are highly efficient variable-speed compressors that use R-290 as a refrigerant.

Details: These Embraco compressors can be applied in commercial refrigerators and freezers both for food retails and for food service applications. These compressors can also bring significant benefits to bottle cooler type applications.

Features: These are variable-speed hermetic reciprocating compressors that are designed for applications from -40°F to +32°F evaporator temperatures using R-290 as a refrigerant. They range in size from ¼ to ¾ HP.

Benefits: These compressors bring a very high level of efficiency in a very small footprint with low levels of sound. The compressor uses a very efficient BLDC motor and is better able to load match, so it uses significantly less energy than a fixed speed compressor of equivalent displacement.

Service, maintenance, and installation: If a contractor is replacing the compressor in the field, the tubing connections on the compressor are the same as any fixed speed. The inverter is the only difference between these compressors and the fixed-speed compressors, but it will be just as simple to replace as the typical relays and overloads contractors are accustomed to seeing.

Warranty information: Manufacturer did not specify.

Product: NTX compressors are high-efficiency fixed-speed compressors that use R-290 (NTX6222U and NTX6225U) and R-404A.

Details: These are all new compressors for this year and are intended for use in large MBP [medium back pressure] applications such as ice machines, walk-in cooler applications, and open-air type refrigerated merchandisers. These compressors can be used in retrofit applications where a lineup of cases is being replaced by plug-in/self-contained style cases, or replacing a condensing unit for a walk-in cooler. These are also intended for new applications.

Features: These compressors use the latest technology from the Embraco brand portfolio, which enables the highest level of efficiency on the market for their size range. The solutions are designed to achieve the new Annual Walk-in Energy Factor (AWEF) standards set by the Department of Energy (DOE). They range in size from ½ to 1 HP.

Benefits: A new highly efficient manifold delivers a significant improvement in overall compressor efficiency.

Service, maintenance, and installation: Manufacturer did not specify.

Warranty information: Manufacturer did not specify.

Product: Polar King Mobile (PKM) refrigerated trailers are available in three sizes — 6 by 8 feet, 6 by 12 feet, and 6 by 16 feet — and are an affordable solution to refrigerated transport for catering companies, restaurants, and farmers who need to transport produce, meat, dairy and other perishables.

Details: Polar King Mobile trailers are designed and engineered specifically for outdoor use. The 100 percent seamless fiberglass design provides a continuous surface, which keeps the insulated structure completely intact — free of moisture damage and bacteria formation. All interior corners are rounded to further ensure a sanitary environment. The NSF-approved flooring system provides a non-slip durable finish, which greatly reduces the risk of slips and falls. With the unit being completely seamless, it can easily be cleaned with a hose without damaging the insulation. Each unit comes standard with a 54-inch wide door suitable for pallets. The unit is powered by the GOVI arktik 2000US refrigeration unit (R-404A), which is rated at 0°F (-18°C) to 50°F (10°C) and runs on 15 amps and 110 V. Suitable for up to 700 cubic feet of refrigerated space.

Features: Unique to Polar King is how the fiberglass exterior design absorbs very little heat because of its natural properties against conductivity. Conventional metal and steel exteriors are actually conductors, thus absorbing and storing much of the heat. This requires the refrigeration system to work overtime; causing maintenance issues, increased electricity consumption and ultimately reducing its longevity.

Benefits: Polar King Mobile is committed to proving a quality product, a business tool, a productive asset that will pay for itself many times over.

Service, maintenance, and installation: Seamless exterior and interior with the ability to clean, power wash inside or outside without harming the unit. Durable long-life span of the Polar King structure itself will lend to years of profitable return on investment. The 110 V, 15-amp refrigeration system allows for ease of use and simple connections.

Warranty information: One-year parts and labor on the Polar King trailer; 90-day parts and labor on GOVI refrigeration unit, with one-year parts.

Product: RLS press-to-connect refrigerant fittings are used to make copper tube connections in high-pressure refrigeration (and HVAC) applications without the need for brazing. They can be used in both new construction and retrofit/repair.

Details: RLS press fittings include couplings, 90-degree and 45-degree elbows, 90-degree street elbows, tees, reducers, caps and more, in sizes ranging from 1/4 to 1-3/8 inches. They are approved for use with a wide range of refrigerants.

Features: RLS press-to-connect fittings are fully registered and listed to UL 207 for pressures up to 700 psi. They are field-proven with millions of fittings installed worldwide since 2015.

Benefits: Advantages include: time savings, as tube connections are made in just 10 seconds; safety, as no flame means no fire hazards; reliability, as the press tool creates a permanent mechanical joint every time; and cost savings, as there are no gas or brazing materials, no hot work permits, no fire spotters, and no nitrogen purging.

Service, maintenance, and installation: Manufacturer did not specify.

Warranty information: Ten-year limited warranty.

Product: Tecumseh ARGUS condensing unit and Designed by LU-VE matched system unit coolers are ideal for walk-in coolers and freezers in restaurants, grocery stores, convenience stores, and other small format retailers. This system was designed due to the updated U.S. Department of Energy (DOE) AWEF (Annualized Walk-In Energy Factor) efficiency regulations that came into effect in January 2020. It can be used in retrofit applications as well as new construction.

Details: The ARGUS air-cooled low- and medium-temperature condensing unit platform features both indoor and outdoor configurations. By applying a combination of reciprocating and scroll compressor technologies, Tecumseh has developed a flexible, simplified platform with OEMs, contractors, and business owners in mind.

Features: The ARGUS is designed specifically for R-452A, R-448A, R-449A, and R-404A and exceeds the DOE’s AWEF requirement by up to 15 percent in the capacity range of ½ to 6 HP. The ARGUS is available in three chassis sizes, which were developed with a simplified layout to make it easier to access without removing the top of the enclosure. Designed by LU-VE is the matched system unit cooler and comes in three evaporator sizes and a capacity range of 3,000 to 60,000 Btuh. The optional PLUG&SAVE electronic expansion valve replaces mechanical thermostatic expansion valves (TXVs) and solenoid valves for precise superheat control and energy savings. It can be used with 24 different refrigerants, including CO2.

Benefits: The ARGUS condensing unit and Designed by LU-VE matched system unit coolers are optimized around HFO-blend refrigerants that exceed the DOE’s AWEF requirement by up to 15 percent in the capacity range of ½ to 6 HP. The ARGUS can be equipped with microchannel coil design, which is up to 50 percent lighter and uses 30 to 40 percent less refrigerant than other coil technologies.

Service, maintenance, and installation: The ARGUS was designed with serviceability in mind. All three chassis sizes were developed with a simplified layout, making it easier to access without removing the top of the enclosure. The base valves on the outside corners of each chassis seamlessly integrate with our competitors’ installations, providing an efficient drop-and-go solution that will streamline workflow and cut costs. Other features include LED lights that activate when system door is opened, allowing visibility in any location or situation; ARGUS Axis System, which allows technicians to easily remove door and streamline service workflow; an enlarged, color-coded electrical diagram, located inside door to ease serviceability; and a QR code, which provides easy access to wiring diagrams, performance data, and service parts list.

Warranty information: Manufacturer did not specify.

Product: The UC1 Series is an energy-efficient, 50-watt, electronically commutated motor (ECM) that is available for evaporators and condensers. The UC1 motor can be used in retrofit applications and new construction and is dimensionally interchangeable with comparable output shaded-pole and PSC unit bearing motors, but it requires a fraction of the electricity to operate. They are also fully programmable and “customizable to the core.”

Details: The IP 55-certified UC1 can be used with all different types of refrigerants including R-448A and R-290. These Class B motors range from 25 to 55 watts and can be programmed with three discrete speeds, ranging from 0 to 2,400 rpm (+/-1 percent). They are also available in both 115- and 220-v, 50/60 Hz, and the operating temperature range is from -40 to +122.

Features: The UC1 exceeds 70 percent in efficiency across a wide range of applications and features constant speed control and complete integration of the electronics into the motor hub.

Benefits: By expediting the testing and approval cycle, Unada can engineer, build, and deploy custom solutions for each unique project. The UC1 is equipped with three-speed, reversible, or timed-reverse options that allow programming in real time. With the Bluetooth app and data logging features on up to six devices, programming and data storage from a phone or tablet is simple. When the motor is controlled by software, customers are able to optimize and integrate the motor, fan, and controller with the application.

Service, maintenance, and installation: No special installation or maintenance requirements. Measures are in place to ensure that work is minimal when it comes to cleaning parts and avoiding motor damage. The timed-reverse feature sets the fan to spin periodically in the opposite direction to clear dirt and dust from the coil and help maintain its peak condition. The soft-start feature ensures any ice build-up is gently broken off to prevent motor damage. There’s also no water ingress during defrost.

Warranty information: Twelve-month warranty from date of invoice. Extended warranties available.

Product: The A+P Penthouse evaporator is the perfect fit for cold storage warehouses and food processing plants. It was mainly designed for new construction but could be configured for retrofit.

Details: The A+P Penthouse unit is designed for maximum versatility and efficiency. Availability for ammonia, Freon, CO2, and glycol systems and capacities from 5 to 90 TR [tons of refrigeration].

Features: Some of the base construction features include structural steel perimeter frame, G235 galvanized metal bracing and support structure, and integrated welded lifting brackets. Optional pitched roof base, side drain connection to roof, and optional drain into building. Access doors are standard on both sides of unit, and galvanized steel grating is on both sides of unit. Interior LED lighting; individual light switches inside each door; and 120 V service outlets on both sides of coil. Tube Axial fans with 1 to 10 HP premium efficiency motors. Insulated panel construction and doors.

Benefits: Colmac’s A+Pro software allows contractors to select or rate A+P penthouse evaporators to match project requirements and provides a complete performance, dimensional, electrical, and installation information. All selections can be sorted and prioritized in order of: lower first cost, lowest operating cost (fan kW/TR), smallest refrigerant charge, lightest weight, and lowest noise level.

Service, maintenance, and installation: Easy access to fan motors; washdown duty components; and stainless steel interior. Normal maintenance for this type of evaporator is required.

Warranty information: B31.5 standard five-year warranty on all pressure-bearing elements (tubes, headers, connections, weld joints) in SST ammonia evaporators. Two-year warranty for all other parts. All units are designed to ship fully assembled.

Product: Evapcold LCR-P and LCR-C low-charge ammonia refrigeration packages provide ammonia safety with energy savings for both new construction and retrofit projects. The factory-assembled, low-charge ammonia technology offers safety and sustainability. Requiring just a fraction of the refrigerant charge associated with traditional field-built industrial refrigeration systems, each Evapcold unit is crafted as a single-source, quick-to-install solution.

Details: LCR-P penthouse models feature low-charge ammonia penthouse design for large freezers and coolers; capacity range of 10 and 100 TR [tons of refrigeration] each; room temperatures ranging from -20ºF to +55ºF; water-cooled or air-cooled condensing; and pump recirculated liquid feed and hot gas defrost for very efficient operation.

LCR-C chiller models feature low-charge ammonia chiller packages for process cooling loads as well as docks, multiple rooms, or smaller rooms with ceiling-hung cooling coils or penthouse coils; range in size from 20 to 400 TR each; process temperatures ranging from +5ºF to +50ºF chilled fluid temperatures; optional heated fluid loop from condenser and oil cooler waste heat recovery; and ground-mounted or roof-mounted, indoors or outdoors.

Features: Evapcold products include several state-of-the-art innovations in heat transfer technology, energy efficiency, and microprocessor control for reliable low-charge operation. Significant features include efficient hot gas defrost, variable-speed capacity control, advanced control logic, and comprehensive documentation, including detailed operating and maintenance procedures allowing for very effective operator training.

Benefits: Evapcold provides inherently safer technology, reducing the regulatory burden to owners and operators, and lowering compliance costs. Systems contain significantly less ammonia than traditional systems and are safer to operate, maintain, and work around. They allow owners to stay below the 10,000-pound threshold quantity mandated by OSHA’s PSM [process safety management] and EPA’s RMP [risk management plan] regulations, provide lower off-site consequences, and reduce owner’s liability and exposure to fines.

Service, maintenance, and installation: The entire system offers simple plug-and-play installation and faster startups with significantly less on-site labor than its field-built alternatives. Maintenance is easy, thanks to evaporator penthouse access doors; evaporator fan/motor removal davits; exterior service panel on machinery room, including the ability to connect a pump-out unit; monorail and hoist for compressor or motor removal, as well as an access panel; walk-in machinery room; stainless steel piping; and isolation valves on major equipment. Pre-engineered, manufactured, and tested systems are simpler to operate than custom-built, field-erected ammonia refrigeration systems. Common system designs and components make training and maintenance easier.

Warranty information: Two-year warranty.

Keeping tight control of the temperature is extremely important in refrigeration systems. That’s because a temperature swing of just a few degrees in one direction or another can ruin fresh and frozen food items, resulting in high losses for the end user. The right controls can also reduce energy costs, and many of the solutions discussed here offer both temperature control and energy savings.

Product: The iJ range of products is designed for use with beverage and food service equipment and was created to respond to the growing demand for higher degrees of aesthetic customizations, greater product quality, and provisions for integration with IoT, supervisor, or BMS systems. The iJ control offers options for embedded high-low voltage protection to Wi-Fi and 3G/4G/5G gateways. The platform is compatible with most system architectures, including those employing the use of flammable or semi-flammable refrigerants.

Details: The iJ platform is available in a wide array of sizes, configurations, and options. The configurations available on this platform include units with one to six relays in several voltage options, including 115/230 V and 12/24 V to support the integration with the manufacturer’s equipment. The unit will also be available as a self-contained control or in a split configuration with a multitude of interfaces for a manufacturer to select from. The available interfaces for the iJ platform can be customized to allow for branding and other aesthetic changes that add value to the application

Features: The iJ offers an impressive range of aesthetic customization. The unit can be customized to meet the most complex design and color pallets imaginable, including incorporating proprietary artwork. The ability to brand and modify the control is a huge differentiator and can act as a significant value add for many customers, especially for specialty applications. The controller’s LED color, keypad functions, and operational icons can also be modified to match the exact function of the unit.

Benefits: The iJ platform has several options for improving unit efficiency and connectivity. The base solution offers the needed outputs to manage variable-capacity compressors from a multitude of recognized manufacturers. The addition of open embedded communication protocols (Modbus) allows end users to integrate the device into existing supervisory or BMS systems to enable the same control and system awareness as units found in larger retail locations. The platform also provides onboard NFC and Bluetooth connectivity. Carel has developed a service app (currently available on Google play and the Apple store) that is available for technicians and manufacturers, allowing the user to communicate with the controller in real time. Users can access alarms, data trending, and the complete operational parameters of the unit.

Service, maintenance, and installation: The iJ platform will use a button-free capacitive touch display allowing users to clean the front of the unit with ease. The IP54 protection option will also ensure that unit cleaning does not pose a risk to the electronics, significantly improving the protection of the control versus the legacy solutions on the market today.

Warranty information: Two years from the date of manufacture. Extended warranties may be available with volume agreements.

Product: The Argos by RAE Corp. can be applied to any and all refrigeration applications, including new construction or retrofit for existing systems made by Century Refrigeration and other OEMs.

Details: Argos is a state-of-the-art refrigeration control system that allows the user to interface in live time. It is a stand-alone web-based program that doesn’t require any special software; simply use a smartphone, tablet, or computer to access. Argos collects and stores the system data, which can also be downloaded for up to a year with the option to purchase extended data time. Data setpoints include condenser fan performance, refrigeration mode, compressor status, compressor unloaders, low-pressure cut out, minimum compressor runtime, maximum compressor runtime, refrigerant fan mode, room temperature, coil temperature, and more.

Features: With a full system dashboard for each project site and remote visibility, users can control their environment from anywhere. This software can provide trending for room temperature, defrost frequency, and product temperature, along with many other operating points. This includes visibility to superheat, suction and discharge pressures, unloading, and more.

Benefits: Not only is it possible to monitor how the system is performing, but the user will be able to make remote setpoint changes and receive critical alarm statuses via email or text message. Because of the ability to immediately make changes to the refrigeration climate, the system will become more energy efficient.

Service, maintenance, and installation: The Argos program is currently available as an option on all Century Refrigeration equipment orders. The hardware can be retrofitted on previously purchased units and on other manufacturer’s equipment in the field.

Warranty information: Standard warranty covers 12 months after installation.

Product: The CO2 Adaptive Liquid Management (CALM) combines Danfoss’s Liquid Ejector and Adaptive Liquid Control (ALC) case controller algorithm to pull liquid CO2 refrigerant from the suction side and inject it into the evaporator of display cases and cold rooms, regardless of climate.

Details: CALM is a complete solution, with not only an intelligent system manager and smart pack and case controllers, but also two Danfoss innovations: the ALC case controller algorithm and the Liquid Ejector. The Liquid Ejector uses expansion energy from the gas cooler to efficiently remove liquid from the suction side. The ALC case controller algorithm then safely injects more refrigerant into the evaporator, increasing evaporation temperature and raising controlling superheat close to zero. Together, these components optimize evaporator performance, increase suction pressure, and decrease compressor energy consumption.

Features: Use of the Liquid Ejector and ALC enable full utilization of the evaporator’s surface to provide — without equipment change — up to 10 percent greater energy efficiency on top of savings inherent with CO2.

Benefits: CALM reduces first-time investments; for example, with less liquid in the suction line, the size of the suction accumulator can be reduced. Required compressor capacity can also be reduced, allowing for smaller or fewer compressors to be used. CALM is a cutting-edge CO2 solution for all climate zones and store sizes and helps food retailers all over the world transition to CO2 as a refrigerant. Increasing the evaporating temperature increases suction pressure, thereby reducing both the compressor load and the energy it consumes. CALM can typically achieve energy savings 5 percent better than minimum competitive active superheat management systems and 10 percent better than fixed superheat solutions.

Service, maintenance, and installation: The physical requirements for the CALM algorithm include Danfoss case controllers (i.e., AK-CC 550A, AK-CC 55) at all evaporators and a Danfoss pack controller (i.e., AK-PC 782A) to control the rack, as well as a suction accumulator with liquid level indicator and liquid ejector connected to the suction accumulator.

Warranty information: Manufacturer did not specify.

Product: The KE2 Edge Manager 35 with wireless sensors is designed to be used to monitor refrigerated spaces from single-door reach-ins to walk-in coolers and freezers on new and existing equipment.

Details: The wireless monitor offers email and/or text message alerts and onboard data logging for up to one year of storage.

Features: The KE2 Edge Manager is designed to combine controllers as well as wireless sensors into a common dashboard, allowing the entire facility’s refrigeration to be monitored on a single screen.

Benefits: Other wireless monitoring solutions require a separate interface for sensors requiring users to go to multiple locations to view all of their connected refrigeration equipment.

Service, maintenance, and installation: Wireless sensors provide quick and easy installation. Periodic battery changes required, using standard AAA batteries. The KE2 Edge Manager will alert the user when the battery requires replacement. Installation requires internet connection for email/text message alerts and remote monitoring. When installing wireless sensors, distance will be affected by obstacles between the sensor and the KE2 Edge Manager.

Warranty information: Warranty is 12 months.

Product: The KE2 Temp + Valve Retrofit Kit is designed to be used on new and existing evaporator coils on HVAC and refrigeration equipment from 3,000 to 84,000 Btuh (1/4 to 7 tons). The kit combines the controller, sensors, and electronic expansion valve (EEV) in a single package, providing an easy grab-and-go solution.

Details: The KE2 Temp + Valve controller combines the functionality of a thermostat, defrost time-clock for air defrost, and EEV controller with pressure/temperature superheat. The controller includes 20 pre-programmed refrigerants, including R-404A, R-448A, R-449A, R-407C, and R-407A.

Features: Communications are easy, as the controller can be run as a stand-alone, or email and text alerts, data logging, graphs, remote monitoring, and control can be easily added with a KE2 EM35.

Benefits: With only four SKUs, the retrofit kit is perfect for truck stock. It replaces thousands of thermostatic expansion valves (TXVs) since it is not refrigerant or application specific. The controller can be used stand-alone to replace a thermostat, potentially saving a trip to the supply house. The KE2 Temp + Valve’s superheat algorithm maintains proper superheat regardless of changes in loading, ambient, etc.

Service, maintenance, and installation: The controller can be used on both medium- and low-temperature applications, including applications requiring maximum operating pressure (MOP). The kit needs to be selected to match the evaporator’s rated capacity. A selection table eliminates the need for a capacity calculation for every evaporator. The controller utilizes an auto switching transformer, allowing it to accept 115 V or 208/230 V incoming power, eliminating the need for an external transformer.

Warranty information: Warranty is 12 months.

Product: Sanhua pressure controls are designed for HVAC and refrigeration applications and can be used in retrofits and new construction.

Details: Sanhua offers a low-pressure control, high-pressure control, and dual, as well as automatic reset, manual, or convertible.

Features: Pressure controls feature durable tin bronze bellows and brass connections for longer life and reliability.

Benefits: Low-pressure controls protect the compressor from overheating by shutting off the compressor if there is a flow restriction in the system — like a blocked filter-drier — or if there is a leak in the system causing a loss of refrigerant. It can also switch on the compressor to maintain a pump down, in the event of some refrigerant leaking past the expansion valve. High-pressure controls protect the system from excessive pressures that could rupture tubing or damage the compressor.

Service, maintenance, and installation: The included mounting place facilitates installation, and no regular maintenance is needed. If the user is replacing a single-pole single-throw control with a dual single-pole double-throw, then refer to the installation instructions included in the box on how to wire the switch correctly.

Warranty information: The warranty is 18 months.

Product: Sanhua’s SEC superheat control kit (SEC613-R4 Kit-LPF) works with any refrigeration, air conditioning, or heat pump (when paired with an external check valve) up to 3.1 tons (R-404A), 4.2 tons (R-448A), and 5.3 tons (R-410A). Compatible with all common refrigerants. This kit will be available in the third quarter of 2020 and will work for both retrofit and new construction applications.

Details: This is compatible with all common HCFC, HFC, HFO, and HC refrigerants and blends, more than 25 in total. Connection sizes currently include ¼ by ¼ inch, ¼ by 3/8 inch, and 3/8 by ½ inch. The kit is compatible with all temperature ranges, including low- and medium-temperature refrigeration. The kit includes a superheat controller, pressure sensor, temperature sensor, and valve stator. An assortment of LPF electronic expansion valves (EEVs) can be paired with the kit in order to select the one sized for a particular application. This is a 500-step unipolar stepper motor valve.

Features: The Sanhua LPF EEV is very tight-seating and as good as a solenoid valve. The stator is a quick-connect design that allows the user to simply place on top of the valve and rotate 90 degrees into position.

Benefits: Being an EEV, this kit offers an energy efficiency savings of 28 percent for a typical walk-in cooler compared to a thermostatic expansion valve (TXV), thanks to the precise and constantly held superheat, reducing the amount of time a compressor needs to be on.

Service, maintenance, and installation: Sanhua has created a YouTube video that demonstrates the easy installation: www.youtube.com/watch?v=NWpGr2N9kUY.

Warranty information: The warranty is 18 months.

Product: The Sporlan S3C Series of case control products provides safety, security, and service for remote and self-contained refrigerated display appliances (single or multiple coil). This controller also serves as the backbone for Sporlan’s walk-in coil control and can be used on retrofits and new construction.

Details: The S3C family of controls includes a case controller, display module, and valve module that all support open protocol communication via BACnet and Modbus. The system is designed to facilitate both installation and integration by the refrigerated appliance OEMs, as well as retrofit into existing supermarket refrigeration control installations. When enabled, the controller provides automated configuration and network integration. The S3C case control peer-to-peer system is capable of standalone or BAS coordinated control of up to eight refrigerated cases per lineup. This family of controls simplifies and shortens the time required to set up new equipment or retrofit an existing system for more precise control.

Features: Features include two S3C valve modules that may be powered by the S3C case control; color-coded temperature sensor wires for ease of installation; control step motor or pulse-width modulation valves; bright, colored LEDs show status of case at a glance; defrost or dual temperature mode via dry contact input; manual valve positioning available through menu; energy-efficient system operation through accurate valve control; and diagnostics report issues with sensors, valves, fans, heaters, etc.

Benefits: This controller is typically set up at the case OEM, so the contractor simply runs the refrigeration lines and connects the power. The contractor or end user can use the free mobile app, Tech Check, to connect to the device to view values, graph, view alarms, reset alarms, change settings, and download history data. Anti-sweat heater control can be done using Sporlan’s relative humidity sensor instead of pulsing the heaters at a constant rate.

Service, maintenance, and installation: The Sporlan Tech Check mobile app provides an extremely easy interface in to the controller to troubleshoot any problem that may be encountered without unloading the case.

Warranty information: Standard warranty is one year.

Summer is upon us, and ice machines around the country are working overtime to make sure customers have enough flakes, cubes, chips, and nuggets to keep their drinks and perishables cold. To keep up with the growing demand for efficient and reliable ice machines, manufacturers are offering new models that are not only easier to clean and service, but that also produce the best-looking — and best-tasting — ice around.

Product: Horizon Elite ice machines can be installed anywhere ice is needed, including restaurants, convenience stores, supermarkets, on-site dining, sports and recreation venues, and more. The product line can accommodate new builds as well as retrofit, due to exclusive remote ice delivery equipment (RIDE) technology, which allows ice machines to be installed anywhere within 75 feet of the dispense point.

Details: The Horizon Elite uses R-404A refrigerant and offers 700, 1,000, 1,400, 1,800, and 2,100 pounds of production capacity per day. The unit features 50° to 90°F inlet water temperature range and 60° to 100°F ambient air temperature range. In contrast to other nugget-type ice machines, regular bearing inspection or replacement is not required. An easy-to-read LED offers operating status and diagnostic display.

Features: The scale-inhibiting design produces ice that has 15 percent the TDS [total dissolved solids] of the incoming water for optimum dispensing and long-life drinks. It quarantines and regularly expels scale-producing dissolved solids to dramatically reduce scale buildup. RIDE automatically transports ice through a tube up to 75 feet away from the dispenser and improves aesthetics, creates a better customer experience, and allows end users to easily clean dispensers. IMDV [ice manager diverter valve] uses RIDE technology to send ice to two dispense points from only one ice machine.

Benefits: Due to reliability and ease of maintenance, refrigeration contractors get satisfied customers and fewer callbacks. End users get a machine with lower overall cost of ownership, so they can focus their attention on their customers instead of the ice machine. Fresh inlet water forces dissolved solids to the reservoir, where they are isolated and expelled in low-volume flushes and can use up to 50 percent less water than other cube-type ice machines. Unlike cube ice machines, Follett ice machines don’t need to reverse the freezing process to melt the ice off the evaporator plate during the harvest process.

Service, maintenance, and installation: Because Horizon ice machines can be installed in out-of-the-way places, its exclusive docking station allows for easy access and install of utility connections, as well as easy removal of ice machine during service. Semi-automatic cleaning process cuts cleaning time down to 15 active minutes and can be performed by any in-store personnel. There are no wear parts on Horizon Elite ice machines, and the only regular maintenance is the National Sanitation Foundation (NSF)-required cleaning and descaling process once every six months. Environmental factors could require more often cleaning, but the patented scale-inhibiting design has been shown to dramatically increase cleaning intervals. Unlike other nugget ice machines, bearing inspection is never required.

Warranty information: Three-year parts and labor warranty, as well as five-year compressor parts.

Product: The Sphere ice machine (IM-50BAA-Q) creates up to 500 1.8-inch ice balls per day, which makes it perfect for bars, restaurants with bar service, nightclubs, and lounges in hotels, casinos, and resorts. Recommended as an additional type of ice for any operation, the clam shell evaporator makes individual ice spheres with dedicated water jets, which is more efficient and sanitary than ice molds and much more profitable than third-party ice vendors. This small undercounter ice machine with built-in 36 pounds storage bin fits easily under a bar for easy access to specialty ice.

Details: The IM-50BAA-Q is 39.5 inches tall, 24.75 inches wide and 20.75 inches deep; uses R-134a refrigerant; has a standard 115-v NEMA 5-15P plug; and uses a gravity drain. With easily removable front panel, louver, and cleanable air filter, the Sphere ice machine is simple to install and service. The LED display in the front shows when the machine is making ice and when it is about to harvest.

Features: The Sphere ice machine creates a unique opportunity for dealers, service technicians, and customers. The return on investment for the Sphere ice machine far outweighs the messiness and time-consuming method of making specialty ice with molds, as well as purchasing sphere or cubes from an ice vendor.

Benefits: The IM-50BAA-Q makes under 50 pounds of ice per day, putting it outside of the normal commercial ice machine production range and AHRI qualifications.

Service, maintenance, and installation: The front panel is easy to remove with a Phillips head screwdriver, which gives access to all controls, filter, and even water and drain lines. The top is removable for access to the ice-making parts for service and cleaning. Installation is easier with a standard 6.5-foot plug and gravity drain. Unit can be turned on or off with the flip of a switch behind the panel. For maintenance, follow the recommended schedule per the installation manual: clean scoop daily; clean air filters bi-weekly; clean external water filters and ice maker exterior monthly; clean ice maker, storage bin liner, water supply inlet, condenser and water hoses annually.

Warranty information: Three-year parts and labor on the entire machine; five-year parts on the compressor.

Product: The Undercounter Gourmet Line (UCG) is designed for commercial use, particularly in restaurants and bars, but can also be used in coffee shops and small chains. The lineup will be introduced in September 2020 and can be used in either new construction, or as a replacement to existing competitor units. The slim design makes it very usable in all spaces, including tight fits.

Details: The UCG is available in four models, ranging from 60 to 130 pounds of production with a temperature range of 50° to 100°F. Bin storage ranges from 18 to 49 pounds. Additional features include:

- Hermetic piston compressor (high-efficiency model);

- Electronic control that is very easily serviceable and energy efficient;

- New thermal sensor indicating bin full;

- Evaporator and condenser probe; and

- Control board, which manages the cycle times and adapts it to ambient and water temperature changes, increasing energy efficiency. Also manages fan cycling.

Features: The UCG lineup features a top-hat style ice cube, which is great for cocktails. Its slim design ranges from 15.5 to 18.5 inches in width, and with adjustable leg heights, every model in the lineup can fit under a counter. It is also 100 percent front breathing and does not require ventilation clearance on the sides, which is perfect for a bar.

Benefits: The UCG is unique in its use of R-290 refrigerant, which offers low GWP and is much more efficient, thus lowering the environmental footprint and cost for end users. The broad lineup and slim dimensions give contractors and end users flexibility in placing this unit, and the clear, gourmet ice is eye-catching to customers.

Service, maintenance, and installation: The UCG lineup is plug-and-play, so it is easy to install, service, and clean. For regular cleaning and maintenance, the spray system, bin, and evaporator are easily accessible and removable. The units are fully front breathing (intake and exhaust) and include a front air filter that is removable without the use of tools. The air filter is durable and flexible for easy removal and cleaning. It is recommended that descaling occur once a year and sanitizing monthly. Simple and sleek design makes for easy cleaning. The bin is very easy to access for cleaning, and the front air filter can be cleaned as frequently as daily if preferred.

Warranty information: Standard warranty is three years parts and labor.

Product: The UN1520 is part of Scotsman’s new undercounter family expansion. Scotsman now offers five different ice form options (flake, nugget, small cube, medium cube, gourmet cube) and four different sizing options (15-, 20-, 24-, and 30-inch widths). Undercounter units are extremely versatile and are perfect for cocktail bars, restaurants, coffee shops, smoothie cafes, office break-rooms, schools, health clubs and spas, laboratories, and training facilities. Because of its compact size and variety of platform options, these undercounter units are perfect for retrofit applications, as well as new construction.

Details: The UN1520 with bin offers nugget-style ice, production capacity up to 167 pounds per 24 hours at 70°F/50°F (125 pounds AHRI certified at 90°/70°), and 57-pound bin storage capacity. The machine uses R-134a refrigerant and features sealed maintenance-free bearings, stainless steel evaporator and auger, and 6-inch adjustable legs.

Features: The machine is ADA compliant when using a floor mount kit, meaning it will fit underneath a 34-inch ADA countertop (reduces unit height to 31.9 inches). It is Energy Star certified; designed, engineered, and assembled in the USA; and is front breathing, so no side clearance required for flexible placement.

Benefits: Easier preventative maintenance procedures due to sealed, maintenance-free bearings. For end users, the sealed bearings results in long-lasting performance. End users will also benefit from its lower energy and water operating costs, along with the better displacement story with nugget ice (drink programs are more profitable) and the customer preference towards the soft, chewable, nugget-style ice.

Service, maintenance, and installation: Power cord, NEMA 5-15P plug, ice scoop, and adjustable legs are included for quick and easy installation. The QR code makes it easy and convenient to access all product/service information and warranty history. Scotsman recommends that the machine is sanitized and descaled every six months. Ensure that back of the unit has at least 4 inches for utility clearance and that the unit is placed near drain.

Warranty information: Three-year parts and labor on all components (warranty valid in North, South and Central America for commercial installations). Contact factory for warranty in other regions. For residential applications, one-year parts and labor.

Back to gallery

Back to gallery