While the AHR Expo itself is not taking place in 2021, innovation in the field of HVACR can never be canceled.

That’s why AHR Expo management and co-sponsors ASHRAE and AHRI were still determined to honor this year’s top products and technologies — live event or not.

“Despite the challenges 2020 has presented, we are committed to recognizing the incredible innovators in our industry,” said Mark Stevens, show manager.

The 2021 AHR Expo Innovation Award Winners and finalists were selected in 10 industry categories — building automation, cooling, green building, heating, indoor air quality, plumbing, refrigeration, software, tools and instruments, and ventilation — and adjudicated by a panel of third-party ASHRAE members. Entrants were evaluated based on overall innovative design, creativity, application, and potential market impact.

Normally, The ACHR NEWS staff would be shoulder-to-shoulder with contractors on the Expo floor, live-streaming the winners’ ceremony and interviewing manufacturers to bring you coverage of everything the upcoming year has in store.

And we’re still here for 2021. Below, you’ll find photos and writeups of each of the 10 award-winning products, plus reviews from HVAC contractors who have worked with them firsthand.

A special shout-out goes to Infinitum Electric’s IEq, the AHR Expo Product of the Year for 2021. To this manufacturer, to all who entered the Innovation Awards, and to the contractors and technicians who use these tools and technologies, you are pioneering the future of HVACR innovation every day.

Back to Winners List

Back to Winners List

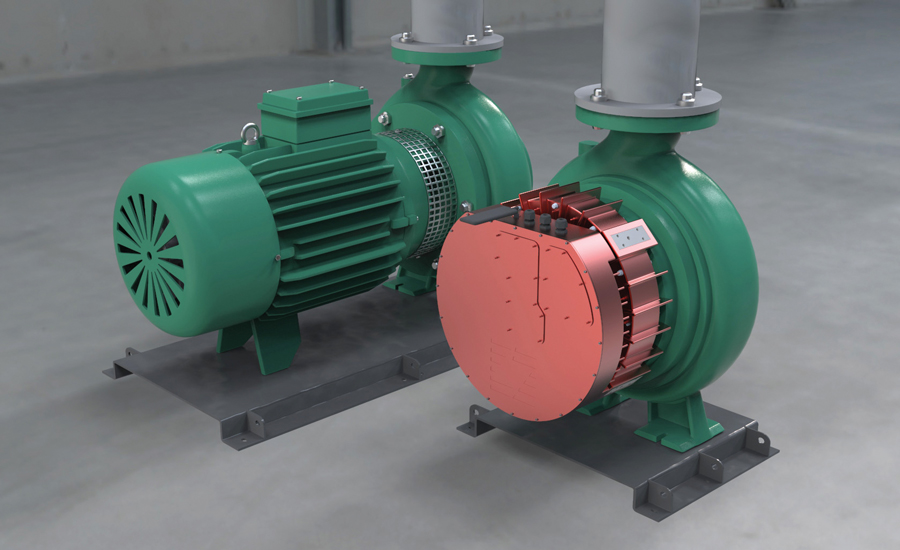

SMALLER AND MORE EFFICIENT: The IEq from Infinitum Electric allows new uses and improves old functions, such as varying the speed of pumps. PHOTO COURTESY OF AHR EXPO

Infinitum Electric Earns Award for 20% Smaller, 98% Efficient VFDs

CHALLENGE:

Creating an alternative solution to replace 30-year-old insulated gate bipolar transistor-based variable frequency drives. VFDs provide both commercial and industrial applications with the ability to vary the speeds of fan, pump, or compressor applications, but efficiency had stagnated in the range of 88-94%.

SOLUTION:

Infinitum Electric used silicon carbide to create the IEq, a VFD that is 20% smaller with a motor control efficiency of 98%. This innovation allows a wide range of OEMs to rethink how they deploy VFDs in ways that were previously unavailable.

PRODUCT DETAILS:

“With leading-edge motor controllers, secure IoT connectivity, and user-centric cloud capabilities, our IEq is engineered to pack a punch,” said Bhavnesh Patel, vice president of business development at Infinitum Electric. “The IEq unlocks new possibilities for OEMs and end users to deploy the technology in the broadest range of environments for greater sustainability and serviceability.”

The IEq includes tightly integrated IoT sensors for vibration, temperature, power, etc.; a microcontroller; and a one-way “data diode” IoT cellular modem gateway, which enables OEMs and end users overseeing multiple facilities to more easily aggregate this data across thousands of installations. The on-board controller analyzes the high-speed IoT sensor data in real-time to provide immediate predictive analytics back to end-users.

Vice President of Marketing

Twin City Fans

FINALISTS:

The first runner-up was the BrainBox AI Solution.

This system studies a building and learns how the HVAC system operates, identifies potential improvement opportunities, and then acts on them, making changes and adjustments in real-time.

The second runner-up was the Verdant ZX Series Energy Management Thermostat from Emerson.

These thermostats have additional relays that can provide real-time occupancy signals in order to control any other electrical device in the room. The device includes built-in Zigbee compatibility, 10-minute self-install, and full online access.

COMPRESSOR TECH: The next generation of Emerson compressors feature a redesigned hermetic motor, plug-and-play electronics, and more. PHOTO COURTESY OF AHR EXPO

Emerson’s Scroll Compressor Designed for Efficiency, Reliability

Product line is prepared for high efficiency requirements coming in 2023

CHALLENGE:

Designing a compressor that can meet upcoming efficiency standards.

SOLUTION:

Emerson’s Copeland™ ZPK7 Fixed Speed Scroll Compressor incorporates technology that will allow manufacturers to meet 2023 efficiency standards without sacrificing reliability.

PRODUCT DETAILS:

The Copeland compressor, now in its seventh generation, is available in a lineup of 1.5-5 ton products with a fixed-speed scroll compressor and is suitable for residential applications.

“The HVAC industry is facing a new set of complex challenges, and Emerson is able to equip contractors, distributors, and manufacturers with next-gen technology and unmatched resources to make informed decisions in this time of significant regulatory changes,” said Martin Leslie, vice president, residential marketing at Emerson. “The Copeland ZPK7 scroll compressor is the most efficient fixed speed compressor ever produced in the 100-year history of Copeland.”

Leslie explained that the compressor supports the HVAC industry with optimized efficiency at key SEER2 and HSPF2 operating conditions. The compressors were designed in light of high-efficiency requirements coming in 2023. He also said that the Copeland ZPK7 product line delivers enhanced efficiency versus the sixth-generation Copeland ZPK6 platform.

“These large efficiency gains are paired with new, innovative compression technology and manufacturing processes that result in a significant reduction in compressor-to-compressor performance variability over the prior generations of product,” said Leslie.

The Copeland ZPK7 compressor uses innovative motor and bearing technology, along with new manufacturing processes, to deliver its high efficiency levels.

Leslie said that the compressor minimizes the magnitude of design change and improves applied cost for the required higher-efficiency air conditioning and heat pump systems needed to meet the 2023 energy standards.

With regulation-ready performance, the compressors are optimized for use with R-410A refrigerant but will also offer a lineup optimized for low-GWP refrigerants, such as R-32 and R-454B.

According to Emerson’s website, the product features a redesigned hermetic motor to improve efficiency and a scroll discharging valve to reduce over-compression at light loads. Plug-and-play electronics work to prevent customers from redesigning their system controllers. It also features harmonized external features to reduce the footprint and simplify tandem designs and oil-injection (in certain models) to mitigate heat in the scrolls.

Vice President, Residential Marketing

Emerson

FINALISTS:

The MrCool Multi-Zone / DIY Series Ductless Mini-Split Heat Pump and Smardt Chiller Group Inc.’s Smardt V-Class Water-Cooled Chiller Range were named as finalists in the Cooling category. MrCool’s mini-split heat pump gives end users customizable options to save energy and monitor their indoor environment, and Smardt’s chillers offer responsive chilled water control in all conditions along with inbuilt redundancy and flexibility with multiple compressors.

ALWAYS IN SEASON: The combination of passive operation for at least half of the year and very minimal energy consumption during active operation for the other half of the year enables such high overall energy recovery. PHOTO COURTESY OF AHR EXPO

Pump-Assisted Heat Exchanger Tops Green Building Technology

Exchanger will allow healthier buildings without sacrificing energy efficiency

CHALLENGE:

When the supply air handler and the exhaust air handler are located hundreds of feet apart from each other, there are few worthwhile options for recovering energy and transferring it back to the supply coil.

SOLUTION:

ACT’s Pump-Assisted Split Loop Energy Recovery Heat Exchanger fills a gap in the energy recovery market for split airstreams.

PRODUCT DETAILS:

Some existing solutions require a lot of energy input of their own, putting a dent in the net return on investment. This Pump Assisted AAHX provides the necessary installation freedom for split air systems while allowing for the maximum amount of net energy savings.

The Pump Assisted AAHX recovers energy from either the exhaust or supply air stream during all seasons, allowing AHUs to consume less energy. Combining traditional air-to-air heat pipe technology and pumped two-phase systems takes advantage of both operational modes.

In passive mode, the heat exchanger operates as a heat pipe with no electrical input required. This mode activates when the warmer airstream is physically below the cooler airstream. When the season changes and the relative temperature of the two airstreams is reversed, a small pump is utilized to maintain the transfer of energy.

Since the method of heat transfer inside of the heat exchanger utilizes the latent heat of the working fluid, the amount of flow rate required to transfer larger amounts of energy is a fraction of an equivalent glycol loop. It’s the combination of passive operation for at least half of the year and very minimal energy consumption during active operation for the other half of the year that enables such high overall energy recovery from this product.

“As the demand for energy efficient buildings continues to soar, the need for high levels of energy recovery becomes a vital component of HVAC system design,” said David Pellicone, lead engineer in the ACT’s industrial products group.

The unit is compatible with both large systems and long distances, and its compact package adds to the design flexibility appeal. The heat exchanger does come with optional temperature control without the need for bypass dampers.

Ultimately, the exchanger (built on-site at ACT’s Lancaster, Pennsylvania, facility) allows designers to create layouts that are better for building air distribution and healthier for their occupants without sacrificing energy efficiency.

Senior Mechanical Manager

Farnsworth Group

FINALISTS:

Easy commissioning, a single part number, and efficiency under all conditions makes the RESET® Certified RadiPac Air-Mover from ebm-papst Inc. ideal for industrial facilities.

Enginuity’s Quadra-Gen engine architecture is almost infinitely scalable, operates with near-zero vibration across all RPM ranges, and cuts particulate emissions by 30% when compared to conventional engines.

AUTO-BALANCE: Radiant systems can become unbalanced over time as changes are made to a home. The RABS solves this with easy installation and system feedback, functioning as a permanently balanced radiant system that provides personal thermal comfort. PHOTO COURTESY OF AHR EXPO

Viega’s Radiant Auto-Balancing Offers User-Friendly Heat Control

The system is easy to install and leads to increased energy efficiency

CHALLENGE:

Balancing a radiant system takes time for a contractor, and a system can become unbalanced over time as changes are made to a home.

SOLUTION:

The Radiant Auto-Balancing System (RABS) by Viega offers easy installation and system feedback, and it functions as a permanently balanced radiant system that provides personal thermal comfort. This saves time and keeps the system balanced automatically.

PRODUCT DETAILS:

“The Radiant Auto-Balancing System (RABS) introduces the ability to monitor the temperature of every return circuit in a radiant system,” said Adam Botts, product manager at Viega. “Coupled with the monitoring of each zone’s air temperature via wireless thermostats, the control actuates flow of conditioned water to each loop, using a learning algorithm to increase the efficiency of a radiant installation.”

The system can maintain set temperatures even with changes in variables like furniture and temporary floor coverings, which allows more flexibility for designers without sacrificing efficiency. Because of the technology, circuit lengths no longer need to be designed to be similar lengths or manually balanced using flow controls on the manifold. Designing circuits of similar length is still best practice, Botts said, but since these designs rarely account for furniture or floor coverings, the system can automatically make proper adjustments to account for environment changes.

“Installers no longer need to spend valuable time balancing a radiant system,” said Botts. “Once the system is connected to a manifold and the web app, the customer can make changes and monitor temperatures with ease.”

This give owners the ability to independently and remotely control each zone in a radiant heating system. Energy-saving features available to owners include schedules, priority heating zones, and the unoccupied feature. The system also incorporates more digitalization of plumbing for monitoring by end users.

The RABS can run on temperature or power levels. Set power levels provide a constant temperature differential that can be tuned to keep floors warm for bare feet.

product manager

Viega

FINALISTS:

Finalists in the AHR Innovation Award Heating category include Ecoer’s Home Comfort Systems with Internet of Things technology, and Burnham Boilers’ Alta Combi. Ecoer’s home comfort system incorporates inverter technology that results in a variable speed system that can maintain consistent comfort levels. The Alta’s control technology continuously monitors flame ionization via the flue gas stream and adjusts the combustion to ensure the boiler is always running at optimal levels.

IT’S A TRAP: The PLP trap is designed to prevent conditioned air from migrating year-round without running dry or allowing the sludge that can develop with sitting water. PHOTO COURTESY OF AHR EXPO

Top Honor in IAQ Goes to PLP Air-Trap

Product prevents conditioned air leakage

CHALLENGE:

To prevent unwanted loss of conditioned air without relying on standing water, especially in applications with limited space.

SOLUTION:

This levered, horizontal pancake designed float-valve with a mechanical advantage about a pivot point lets the PLP, designed by Des Champs Technologies, work equally well year-round, regardless of air conditioner use.

PRODUCT DETAILS:

The Series PLP Air-Trap is the first air conditioning condensate trap to use air pressure developed by the air conditioner fans to prevent conditioned air from entering or leaving the unit. For a hundred years, the P-trap, a carryover from use on toilets and sinks, has been used on a/c equipment to prevent air loss. Unlike the P-trap, the PLP was designed specifically for HVAC equipment and does not require standing water to prevent air leakage.

Air conditioning equipment produces condensate mostly during summer.

The remainder of the year, little or no condensate is produced, so the P-traps are dry most of that time, allowing air leakage. When they do have water in them, the bottom of the trap is prone to develop sludge and growth.

In almost all cases, the PLP will be compared to standard positive pressure HVAC P-trap. If the standard P-trap dimensions are used, it will be dry a month after condensate ceases because of water evaporation. So for seven months of the year, the air conditioner unit will be blowing conditioned air to ambient.

On the other hand, if it were designed to hold water all year and provide an air seal, then it may freeze and break.

The PLP operates dry when no condensate is being produced and uses a levered, horizontal pancake designed float-valve with a mechanical advantage about a pivot point. This allows the PLP to require less than 3 inches of height for up to 40 inches w.c. pressure, instead of the 8 to 60 inches required for a standard P-trap.

Therefore, the company said, the new PLP solves these problems associated with a P-trap and has no inherent problems of its own.

Using the PLP, one size fits ¾-inch to 2-inch piping, with fittings.

founder

Des Champs Technologies

FINALISTS:

The Play-UV Diffuser from EffectiV HVAC combine high-efficiency filtering, sanitizing, and diffusion to help contain the spread of airborne diseases in commercial and institutional buildings.

The Q-Trak Indoor Air Quality Monitor Model 7575 provides quick, accurate information to assess key indoor air quality parameters.

EVERY WHICH WAY: The AngleMix is the first thermostatic mixing valve with an angle-styled body on the market. PHOTO COURTESY OF AHR EXPO

Caleffi Introduces ThermoStatic Mixing Valve With Angle-Styled Body

Geometry minimizes elbow requirements

CHALLENGE:

Making a thermostatic mixing valve with an angle-styled body.

SOLUTION:

The AngleMix™ Angle-Style ThermoStatic Mixing Valve from Caleffi Hydronic Solutions is the only such product on the market. This geometry minimizes the number of elbows required, which reduces overall installation cost. Additionally, AngleMix is the industry’s only thermostatic mixing valve that can close off its hot and cold ports at 100% tightness, preventing temperature creep or droop. This also eliminates the need for bypass/return balancing valves. The valve is certified to ASSE 1017 standard for point of distribution domestic water systems.

PRODUCT DETAILS:

The AngleMix controls mixed water temperature in residential and commercial domestic hot water systems. It mounts at the tank-type or tankless-type water heater outlet, and the angle-style body mixed temperature outlet is in line with the water heater outlet. This facilitates straight-line piping, which reduces pipe elbows and overall space required for installation.

The valve is well suited for low-flow fixtures, with accurate mixing all the way down to 0.5 gpm.

The AngleMix has a lockable set point adjustment knob and includes a temperature gauge on the mixed temperature outlet for verification of temperature. The anti-scale internal components minimize service requirements and extend the life of the valve. The components also compensate for temperature and pressure fluctuations of the incoming hot and cold water.

Available in a wide variety of end connections, the angle style body design is compatible with all common pipe types and connection styles from ½-inch to 1-inch sizes. AngleMix is certified to ASSE 1017 standard for point of distribution domestic water systems. A variety of union tailpieces are available, including press, sweat, NPT, PEX F1960, or F1807, and a different type for each connection can be selected if desired.

“This award reflects our commitment to bringing state-of-the-art engineered solutions that benefit our customers and the entire industry,” said Mark Olson, general manager and CEO of Caleffi North America.

Standard Oil

FINALISTS:

The first runner-up was the electronic water heater with smart integrated mixing valve from GE Appliances, a Haier Company. The flexible capacity units include normal, high, and extra-high capacity settings. When more hot water is needed, the high and extra-high capacity settings activate the integrated electronic mixing valve to maximize performance. The second runner-up was the Uponor PP-RCT pipe and fittings. This is a large-diameter piping system that works seamlessly with Uponor PEX systems.

COST-EFFECTIVE SOLUTION: The CD600 range of large CO2 transcritical compressors makes CO2 booster systems a cost-effective solution for large industrial applications. PHOTO COURTESY OF AHR EXPO

Refrigeration Award Recognizes Cost-Effective CO2 Compressors

Officine Mario Dorin SpA’s CD600 Range is the largest transcritical platform available

CHALLENGE:

To allow the use of natural refrigerant (CO2) in industrial applications, offering a valid alternative to the use of ammonia.

SOLUTION:

The CD Series is already the widest range available on the market, but the CD600 range of large CO2 transcritical compressors makes CO2 booster systems a cost-effective solution for large industrial applications — where in the past, the only alternative was using a large number of smaller compressors.

PRODUCT DETAILS:

The CD600 Range is the largest CO2 transcritical compressor platform available worldwide. Based on a six-cylinder design, this platform includes models up to 100 hp and 2,200 cfh with utmost efficiency levels and premium reliability standards.

This new range of compressor is unique in the market because it nearly doubles the refrigeration duty deliverable with a single compressor. This often leads to a lower number of refrigeration racks and allows for a smaller required footprint for machinery. What’s more, the limited footprint and height allow for a decrease in installation and building costs when compared to an ammonia solution.

“Up to now, competitive products featured much smaller compressors models, which made it very difficult to implement CO2 as a mainstream refrigerant in industrial applications, where large refrigeration duties are often involved,” said Alessandra Chighine, communication and marketing executive at Officine Mario Dorin SpA. “These new compressors are unique in that they nearly double the refrigeration duty deliverable with a single compressor.”

Another unique feature of the CD600 range compressors is that they feature an external discharge manifold, making it possible to sensibly decrease oil temperature and discharge temperature. The external manifold is also very large, making it possible to almost eliminate pressure pulsations in the discharge line. In addition, the enhanced design ensures proper lubrication in all the most critical compressor parts, as the oil throw is extremely limited, thus positively impacting the system COP and the ease of oil management.

“This new compressor platform allows the ability to cost effectively and efficiently apply CO2 in large applications where the end user seeks an alternative to ammonia,” said Chighine.

“It makes CO2 booster systems a really cost-effective solution for those large industrial applications, where in the past, the only alternative was using a large number of smaller compressors.”

Sales Manager

Dorin

FINALISTS:

Ebm-papst Inc.’s AxiEco Protect Axial Fans are designed for use in evaporators, heat pumps, and other ventilation and air conditioning devices that require particularly robust fans.

Emerson’s Copeland™ Digital Outdoor Refrigeration Unit, X-Line Series features a slim profile and lightweight design and is intended for use in medium-temperature walk-in coolers and display cases in convenience stores, small-format stores, and restaurants.

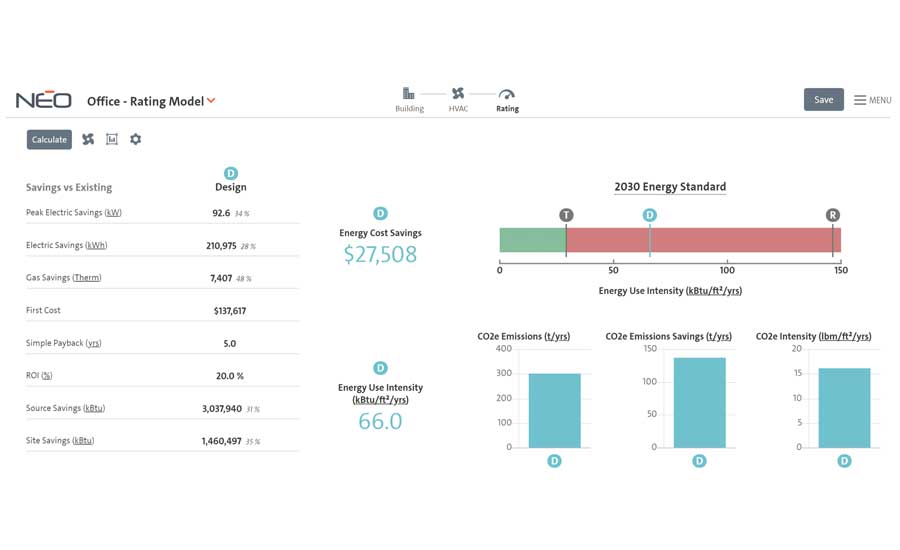

SOFTWARE SOLUTION: NEO automated modeling saves time and money by reducing the number of hours it takes perform an analysis.

Willdan NEO|Net Energy Optimizer Helps HVAC Contractors Tackle Energy Modeling

The software solution can help show decision makers the value of upgrades to their buildings’ systems

Challenge:

To optimize energy modeling for buildings, since modeling is a valuable tool that is underused due to traditionally being time-consuming and complicated.

Solution:

NEO leverages automation to make energy modeling easier, faster, and more accessible, regardless of building size or the contractor’s technical expertise. The NEO|Net Energy Optimizer provides an advanced technology solution that makes energy modeling more accessible, accurate, and affordable.

Product Details:

NEO uses default inputs derived from industry standards (ASHRAE, COMNET, and RS Means) to inform and automate baseline models. NEO provides results in seconds, so its automated modeling saves time and money by reducing the number of hours it takes perform an analysis and makes the design and product selection process significantly more efficient.

NEO is a web-based energy modeling tool that utilizes the DOE-2 simulation engine and provides energy conservation measure rating analyses, energy audits for existing buildings, code compliance, and more. The energy modeling software streamlines whole building analyses of HVAC systems and energy conservation measures for commercial buildings with the versatility to support product comparisons, existing building energy audits, and new construction from early design through construction.

“With evolving construction technology, more stringent building codes, and limited project resources, the impact of design decisions continues to grow,” said Eric Flower, software account executive for Willdan. “NEO helps drive increased efficiency, reduces dependency on fossil fuels, and promotes new technologies by giving stakeholders performance-based answers to their complex product selection, building audit, or new construction design decisions.”

NEO graphically reports results, generates downloadable input/simulation files, and creates CSV and MS Word documents detailing key model inputs and outputs. NEO is web-based, touch friendly, and requires no software installation. Flower explained that NEO provides the actionable data needed to prove the energy, environmental, and financial value of a systems decision. This can help teams embrace new technologies that they may have initially dismissed due to an upfront cost.

“As the NEO user becomes a more educated consumer, supplier or consultant, a circular feedback loop influences: Designers to build more efficient buildings, operators to run them optimally, and equipment manufacturers to build more efficient systems to meet market demand,” said Flower.

Farris Engineering

Finalists:

Finalists in the AHR Innovation Award Software category included Distech Controls’ Builder and Lennox International Inc.’s CORE Service App. Lennox’s CORE service app connects with its products’ CORE systems, allowing for diagnostic features that reduce service, installation, and maintenance costs.

ONE INSTRUMENT: The D-TEK 3 can detect traditional refrigerants, CO2, and flammable refrigerants by simply changing the sensor, all with one instrument. PHOTO COURTESY OF AHR EXPO

Tools & Test Instruments Award Honors Leak Detector

D-TEK 3 leak detector works with multiple refrigerants

CHALLENGE:

For many HVACR technicians, locating and repairing leaks is a vital part of their job, and having one accurate and reliable leak detector — rather than multiple detectors — can make all the difference.

SOLUTION:

D-TEK® 3 is designed to use INFICON’s next-generation infrared sensors, allowing one detector to search for leaks from traditional refrigerants as well as CO2 and flammable refrigerants with just a quick sensor change. D-TEK 3 also brings increased performance and functionality that will save technicians time when locating leaks.

PRODUCT DETAILS:

D-TEK 3 is for use with all kinds of refrigeration and air conditioning systems, commercial as well as residential. Technicians can use D-TEK 3 to leak check newly installed systems, as well as pre-existing systems while performing routine maintenance and repair.

“My favorite feature of D-TEK 3 is its ability to detect traditional refrigerants, CO2, and flammable refrigerants (coming soon) by simply changing the sensor, all with one instrument,” said Austin Toner, product engineer of service tools at INFICON. “Before, technicians would need a separate instrument for each gas. We were able to improve the sensitivity of the infrared sensor to 0.03 oz./year (1 gram/year), while maintaining a 1,000-hour sensor life with no degradation. All that, powered by a lithium ion battery that will charge faster and last longer than previous D-TEK leak detectors.”

INFICON spent years developing the newest D-TEK leak detectors, as the company wanted to bring an even better product to market at the same price to the customer, said Toner.

“I think it’s really cool that D-TEK 3 has many of the same internal components as its big brother, D-TEK Stratus (refrigerant leak detector and portable monitor), both having the same sensitivity and battery life,” he said. “I believe D-TEK 3’s versatility, including the ability to detect traditional refrigerants, CO2, and soon flammable refrigerants, is one of the features that sets D-TEK 3 apart from the competition.”

Service Technician

Creator of HVACR Survival videos

FINALISTS:

Alert Labs’ Sentree A/C Monitoring System provides 24/7 real-time remote monitoring of residential central air conditioning systems to track a/c health. When unusual activity occurs, Sentree provides HVAC contractors with the information they need to proactively diagnose the issue and dispatch the right service to the property.

H2O Weld LLC’s Oweld Water Gas Generator uses electrolysis to produce a neutral flame, which can be used to weld, braze, or solder all non-ferrous materials in a short time.

AFFORDABLE SOLUTION: The CAR3 provides a low-cost solution to balancing forced-air HVAC systems, eliminating the need for on-site balancing. PHOTO COURTESY OF AHR EXPO

Ventilation Award Goes to the CAR3 Air Regulator

Aldes’s constant flow air regulator works off system pressure

CHALLENGE:

Motorized, dampered zoning systems can be plagued by wide variations in duct pressure, resulting in little to no control over airflow delivery rates.

SOLUTION:

The CAR3® is a pressure-independent balancing damper that automatically regulates airflow in duct systems to constant levels. It requires no electric or pneumatic power or sensors and works solely off system pressure. Unlike traditional manual dampers, the CAR3 compensates for changes in duct pressure caused by stack effect, operable windows and doors, wind, loading filters, etc.

PRODUCT DETAILS:

The CAR3 provides a low-cost solution to balancing forced air systems for HVAC systems, eliminating the need for on-site balancing. The CAR3 will regulate airflow in supply, return, or exhaust duct systems and is designed to complement Aldes register assemblies. It can also fit inside standard rigid round ducting, as well as fittings such as take-offs, tees, etc., with a double-lip gasket around the circumference, ensuring a tight, no-leak fit.

“The patent-pending dual-side airflow adjustment dial and cfm indicator allows contractors to set or change the airflow quickly, in supply or exhaust applications, without removing the CAR3 from the duct,” said John Harrell, president of Aldes North America. “Quick and easy to install, the CAR3 saves cost, is easy to maintain, and offers a seven-year guarantee. Plus, it’s made in the USA.”

The CAR3 technology is capable of maintaining constant airflow within +/-10% of the scheduled flow rates, within the operating range of 0.12 to 1.2 inches w.g. differential pressure for low-pressure models (CAR3-L),

or 0.4 to 2.8 inches w.g. for high-pressure models (CAR3-H), providing the broadest airflow control range per diameter in the industry, said Harrell. CAR3 solely operates on duct pressure and will be rated for use in air temperatures ranging from -25°F to 140°F (-32°C to 60°C). Each CAR3 is built using a proprietary blend of amorphous thermoplastic resin treated with antimicrobial, anti-static, and flame-retardant materials to provide reliability and longevity.

Senior Engineer

ADE Systems Inc.

FINALISTS:

Ebm-papst Inc.’s AxiEco Perform Axial Fans are now also suitable for high back pressure, so that ventilation and air conditioning devices can benefit from higher airflow rates.

Kingspan Insulation LLC’s KoolDuct is an innovative pre–insulated HVAC ductwork system that offers reduced installation time, low weight, space savings, increased performance, and energy efficiency.

Back to Winners List

Back to Winners List