In this month’s troubleshooting situation, the equipment that needs servicing is a split system and the refrigerant flow control is handled via an EEV (Electronic Expansion Valve, shown in Figure One, top).

In addition to the valve itself, an EVC (Electronic Valve Control board) and two sensors are employed to control refrigerant flow. One sensor is known as an ET, which is designed to monitor evaporator temperature, and the other is a GT, which is designed to monitor refrigerant vapor temperature, and it is positioned on the suction line side of the evaporator coil. Figure Two shows you the design of the system sensors.

Figure Two (Courtesy of Jim Johnson)

When you arrive in response to the general complaint that the system isn’t keeping the area comfortable, you find that the system’s electronic control and fault code indicates via the LED system that there is a problem in the EEV system that controls the flow of refrigerant and maintains proper superheat. When you check the manufacturer’s information you find that the sensors are in their proper locations.

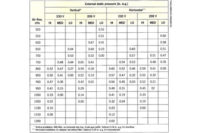

As your next step, per manufacturer troubleshooting procedures, you turn the thermostat system switch off, turn the fan switch to on, and after a 10-minute run time, you measure and record the return air temperature. When you find that the DC voltage measurements at the EVC don’t correspond to the recorded return air temperature, you continue with the required voltage and resistance tests, and you find a zero ohms reading from the ET sensor lead to ground.

Your troubleshooting question: What is the next step you need to take in servicing this equipment?

Compare your answer with ours here.