Part 1 of this article covered how to calculate total temperature glide, effective temperature glide, fractionation, average evaporator and condenser temperature, evaporator superheat, and condenser subcooling for refrigerant blends that have a temperature glide. This article will offer a quick review of evaporator superheat and condenser subcooling calculations, then create a scenario where a service technician chooses the incorrect dew and bubble point value from the pressure/temperature (P/T) chart when calculating evaporator superheat and condenser subcooling.

Temperature Glide Recap

As mentioned in Part 1, the HVACR industry is in the process of researching new low-GWP refrigerants and refrigerant blends that can be incorporated into refrigeration and air conditioning systems. ASHRAE Standard 34 classifies some of these new refrigerant blends as A2L, meaning they are lower flammability with lower toxicity. Many of these new blends are 400 Series, which means they have a temperature glide when evaporating and condensing.

Many refrigerant blends have temperature glide when they change phase in both the condenser and evaporator. The amount of temperature glide depends on the refrigerant blend’s makeup and the system design. In the evaporator, the refrigerant changes phase (evaporates) from a liquid to a vapor, while in the condenser; the refrigerant changes phase (condenses) from a vapor to a liquid. As these refrigerant blends phase change (evaporate and condense), there is a change in their composition by preferential evaporation or condensation of the more or less volatile component in the blend. This process is referred to as blend fractionation.

When dealing with refrigerant blends that have temperature glide, as the liquid refrigerant boils in the evaporator, the composition of the liquid and vapor phases are different. The liquid phase becomes richer in the higher boiling point component as the low boiling point components boil off into the vapor phase. In the condenser, as the refrigerant vapor continues to condense, the vapor phase becomes richer in the low boiling point components as the higher boiling point components of the refrigerant blend condense to a liquid. So, again, the composition of the liquid and vapor phases are different as condensation takes place.

Calculation Review

In Part 1, R-407C was used to illustrate the refrigerant total temperature glide, evaporator superheat, and condenser subcooling using a refrigerant blend’s pressure/temperature chart. R-407C is a refrigerant blend consisting of three HFC refrigerants: R-32 (23%), R-125 (25%), and R-134a (52%). R-407C was arbitrarily chosen for these examples because of its large temperature glide when evaporating and condensing.

The following given conditions are for a summer air conditioning application incorporating R-407C as the refrigerant:

| Suction (evaporating) pressure | 70 psig |

| Head (condensing) pressure | 180 psig |

| Evaporator outlet temperature | 56°F |

| Condenser outlet temperature | 74°F |

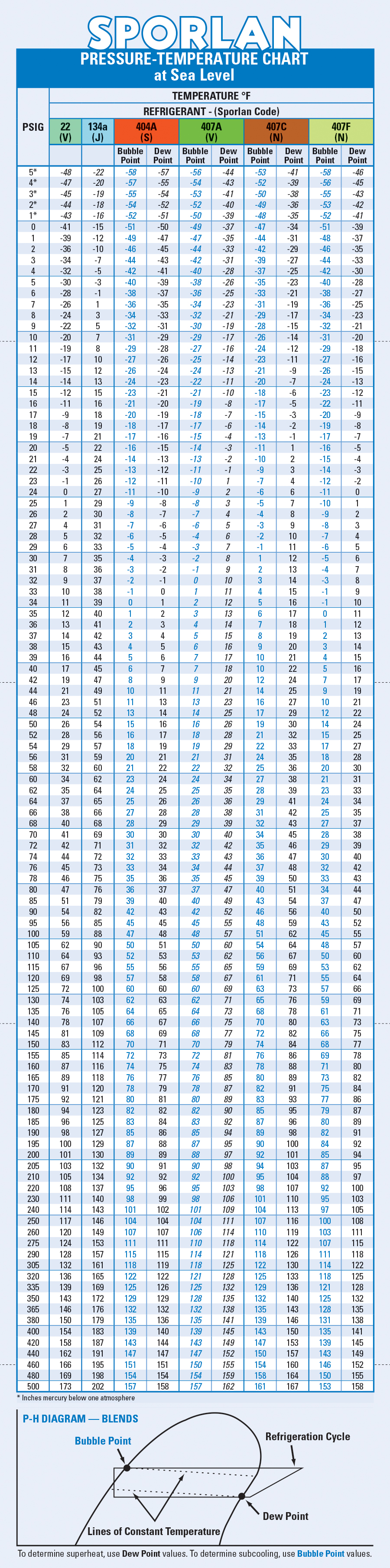

Table 1 shows that for a suction (evaporating) pressure of 70 psig, the saturated liquid temperature is 34°F and the saturated vapor temperature is 45°F. This would give the evaporator a total temperature glide of 11°F (45°F – 34°F). The saturated vapor temperature of 45°F is referred to as the dew point temperature, and the saturated liquid temperature of 34°F is referred to as the bubble point temperature.

TABLE 1: Pressure-temperature chart. (Courtesy of Sporlan Division, Parker Hannifin

Click table to enlarge

Since superheat is defined as any sensible heat gained after the saturated vapor point in the evaporator, the evaporator superheat would be 11°F (56°F – 45°F), where 56°F is the evaporator outlet temperature and 45°F is the saturated vapor (dew point) temperature corresponding to 70 psig evaporator pressure. When HVACR service technicians are calculating superheat values, they must always use the dew point values from the pressure/temperature chart shown in Table 1.

Table 1 also clearly shows that for a head (condensing) pressure of 180 psig, the saturated liquid temperature is 85°F and the saturated vapor temperature is 95°F. This would give the evaporator a total temperature glide of 10°F (95°F – 85°F). The saturated vapor temperature of 95°F is referred to as the dew point temperature, and the saturated liquid temperature of 85°F is referred to as the bubble point temperature. When calculating subcooling values, always use the bubble point values from the Table 1.

Since subcooling refers to a liquid and is defined as any sensible heat lost after the saturated liquid point in the condenser, the condenser subcooling would be 11°F (85°F – 74°F), where 74°F is the condenser outlet temperature and 85°F is the saturated liquid (bubble point) temperature corresponding to the 180 psig head (condensing) pressure.

Incorrect Choice

In the above evaporator superheat example, the evaporator superheat turned out to be 11°F, which is an acceptable evaporator superheat for an air conditioning system incorporating a TXV as the metering device. However, what if the technician used the bubble point value instead of the dew point value when calculating evaporator superheat?

HIGHER GLIDE: Unlike R-410A, some of the newer A2L refrigerants have a higher glide, so technicians must pay close attention to the P/T chart. (Staff photo)

In this scenario, per Table 1, the incorrect evaporator superheat would be 22°F (56°F – 34°F), where 56°F is the evaporator outlet temperature and 34°F is the saturated liquid (bubble point) temperature corresponding to 70 psig evaporator pressure. The incorrect 22°F evaporator superheat value will certainly mislead the technician into thinking that the system is not operating properly.

In the above condenser subcooling calculation, the condenser subcooling turned out to be 11°F, which is an acceptable amount. However, what if the technician used the dew point value instead of the bubble point when calculating subcooling? The incorrect condenser subcooling value would then be 21°F (95°F – 74°F), where 74°F is the condenser outlet temperature and 95°F is the saturated vapor (dew point) temperature corresponding to 180 psig condensing pressure. The 21°F incorrect condenser subcooling amount will certainly mislead the technician into thinking that the system is not operating properly.

Scenario 1

In the above example where the technician chose the wrong dew and bubble point values from the P/T chart, the incorrect evaporator superheat was 22°F and the incorrect condenser subcooling was 21°F. These incorrect readings may lead the technician to think that there could be a restricted liquid line backing up liquid in the condenser while simultaneously starving the evaporator. In reality, both the evaporator superheat and condenser subcooling values were both 11°F, indicating that the system is operating properly.

Scenario 2

What if the service technician only calculated evaporator superheat wrong — by using the bubble point value instead of the dew point value from the P/T chart — and then calculated the condenser subcooling value correctly? The service technician would see 22°F of evaporator superheat and 11°F of condenser subcooling. This normal subcooling may lead the technician to believe the system is not undercharged; however, the high evaporator superheat could lead the technician to think that the evaporator is being starved from a TXV out of adjustment. This scenario could lead the technician to open the TXV more in order to fill out the evaporator and make it more active. This action could cause the compressor to flood and/or slug with liquid refrigerant and do serious damage to the valve structures and mechanical parts within the compressor.

Scenario 3

What if the service technician only calculated condenser subcooling wrong — by using the dew point value instead of the bubble point value from the P/T chart — and then calculated the evaporator superheat value correctly? The service technician would see 21°F of condenser subcooling and 11°F of evaporator superheat. This high condenser subcooling and normal evaporator superheat could lead the technician to believe that the system is overcharged with refrigerant. The technician may recover some refrigerant, leaving the system undercharged from the incorrect subcooling reading.

It is for these above scenarios that service technicians must always follow what the P/T chart instructs them to do when calculating superheat and subcooling values for refrigerant blends with a temperature glide. When HVACR service technicians are calculating subcooling values, they must use the bubble point values from the pressure/temperature chart, and when calculating superheat values, they must always use the dew point values from the chart.

System design, performance, and service conditions must be evaluated when incorporating or retrofitting with a refrigerant blend incorporating temperature glide. Always follow the manufacturer’s guidelines before retrofitting with any refrigerant or system performance could be affected and injury may occur.