When Nathan Dills took over operations at ACP Sheet Metal Company (ACPC) from his father, Harold, in 2013, he made certain that the 41-year-old, Oklahoma-based sheet metal fabricator continue its long-standing tradition of embracing new technology.

“My father had the opinion to never be scared of technology,” says Dills, who serves as president of ACPC and managing partner of its sister company, Midwest Fabricators, LLC. Harold passed away in 2015. “As much as any contractor can afford, technology is one of those things that they have to invest in.”

ACP Sheet Metal specializes in the design, fabrication and installation of duct in commercial and industrial buildings as well specialized fabrication. This includes the design and fabrication of duct components for very large public safety centers, hospitals, universities and sports and performance centers.

Dills was looking to advance the speed and accuracy of ACPC’s cutting machines and improve the interoperability between its design and manufacturing systems when he called upon Mestek Machinery for help with increasing precision and productivity of its hardware. Mestek recommended a complete software and hardware solution.

After purchasing Mestek’s coil line, plasma and water jet insulation cutting machines, ACPC was able to pair the machines with its Trimble FabShop (formerly Vulcan) suite of detailing, estimating and CAM cutting software, cutting down on material waste and strengthening its building information modeling (BIM) system in the process.

Once models are detailed in DuctDesigner 3D, drawings can be exported to AutoBid Mechanical and AutoBid SheetMetal to generate pricing reports and project cost estimates. Or, they can be sent directly to Trimble FabShop CAM software to start fabrication within minutes using a cutting machine.

“They had the software, they just didn’t have all the hardware to circle this whole thing around,” explains Mike Bailey, vice president of sales for Mestek. “With everything talking to each other, they’ve been able to cut their material waste in half.”

But waste is only half the battle, Bailey explains.

“You can optimize material a lot better, you can move the material a lot better, and you can also cut down on labor, which is the problem in the industry right now,” says Bailey. “That’s the biggest cost. Every contractor is trying to figure out how to drive labor out of projects.”

Mestek has several long-standing hardware brands under its umbrella — Engel Industries, Iowa Precision, ISM and Lockformer, to name a few — that enable the company to deliver a full range of metal forming solutions that range, from a single cheek bender to fully automated HVAC manufacturing lines. But its Mestek’s close relationship with Trimble that allows sheet metal fabricators to streamline their hardware and software systems, says Bailey.

As part of their workflow, ACPC uses AutoCAD Revit for 3D model creation and sharing and Naviswork for clash detection. DuctDesigner lets them set up specific company standards, fabrication, and project settings within the tool’s data editor. The hanger point tool is also useful for spacing points along a duct run to save time and ensure accuracy.

“It’s really about the complete solution that’s all interoperable, and it’s a joint effort between Mestek and Trimble to help ACPC save time and labor and to increase productivity,” he says. “It’s a software, hardware relationship, seamless between the two.”

ACPC begins a project by building and detailing the sheet metal components in Trimble’s DuctDesigner 3D, a CAD detailing software that has 3D modeling capabilities and AutoCAD compatibility. This helps deliver greater productivity and efficiency during the design phase.

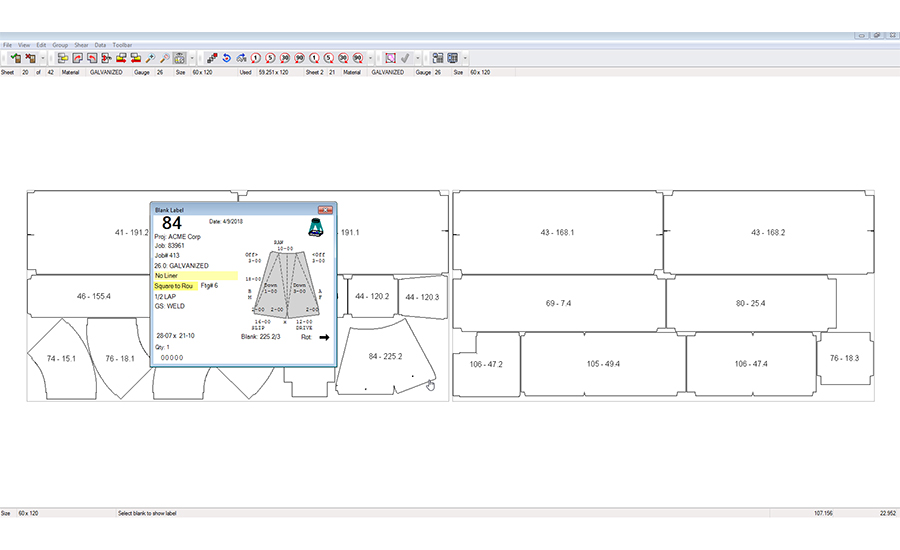

With Trimble FabShop, ACPC operators also have greater control over how fittings are entered, formed and fabricated with options for standard and specialty fittings. DuctDesigner allows ACPC to set up specific company standards, fabrication, and project settings within the tool’s data editor. DuctDesigner is also integrated into ACP Sheet Metal’s project workflow, with connections to Trimble FabShop CAM software.

“DuctDesigner gives our models more consistency and accuracy and warns us if fittings don’t meet our duct construction standards,” Dills explains. “It highlights invalid fittings like a transition offset that exceeds so many degrees. It’s not that these types of errors would get through to fabrication, it’s that now we can find and fix them so much faster, we don’t waste time or spend extra money on rework.”

Dills says ACPC can now fabricate less expensively, faster and safer, and its automated bidding and estimating process is now more accurate and twice as fast compared to conventional methods.

Once models are detailed in DuctDesigner, drawings can be exported to AutoBid Mechanical and AutoBid SheetMetal to generate pricing reports and project cost estimates. Or, they can be sent directly to Trimble FabShop CAM software to start fabrication within minutes using a plasma and insulation cutting machine as well as a fully automated HVAC Iowa Precision Duct Line.

“We knew we wanted an estimation process that was much more automated and would help us create more detailed and accurate estimates,” Dills says. “With AutoBid, we can perform takeoffs directly from electronic 3D CAD drawings, which means we can generate estimates and takeoffs in a much faster timeframe.”

AutoBid includes pre-built assemblies, automatic fitting generation, and integration with the Trimble DuctDesigner 3D detailing solution. The software allows operators to box in an area for takeoff and convert shapes from rectangular to round. The software also automatically generates fittings, pulling data from a SMACNA-based duct standards library to insert the correct fittings and hangers according the specifications.

Dills believes that with Trimble’s FabShop CAM cutting software, detailing CAD software and cutting tables from Mestek, his team can produce duct much more effectively and efficiently than they could previously. ACP Sheet Metal recently completed a rush fabrication job for a panicked customer out of Texas that was left out to dry when their current sheet metal contractor couldn’t meet a job schedule.

Used with the Trimble suite of office software, Dills estimates about a 24 month return on investment for the Vulcan Plus 5” X 20” plasma cutting machine.

“I can produce duct much faster than my guys can hang it. We’ve gone from a seven-to-10 day turnaround to a four- or five-day turnaround,” says Dills. “Not only have we increased shop productivity and efficiency, we also cut our waste by about 60 to 70 percent, allowing us to use more of a roll of insulation than we could before.”

He adds, “Bottom line is we’re experiencing greater output with less input and optimal material utilization.”

In short, the sheet metal fabrication has come a long way since Dills’ father founded the company in 1977. He can still remember knocking duct together by hand at seven years old. “On Saturdays, my brother and I would go to work with my dad. He would go over to work on an estimate, and we would go in the back to knock duct together. When I turned 16, I was the delivery driver all summer long.”

But what hasn’t changed and has remained is the company’s commitment to customer satisfaction and making sure they did the job right.

“What Mestek’s technology has allowed us to do is attain more work, which is a perk for our company. Every job we bid and ask ourselves, if we get it, can we man it. So it’s had a very strong impact on how we do our business,” says Dills. A stronger relationship between his company’s hardware and software has allowed him to focus on quality over quantity when it comes to ACPC’s workforce. “My father didn’t have to know how to run every piece of equipment he purchased, but he had to have the right workers in the driver’s seat.”

With interoperable technology at ACPC’s fingertips, Dills was able to overcome rising material costs by introducing labor saving technologies. Now, like his father before him, he has more time to focus on who he puts in the “driver’s seat.”