Manufacturing is a lengthy process with numerous steps involved. If you are into healthcare, defense, aerospace, marine, oil, gas, or transportation, you must be familiar with the amount of effort it takes to cut and shape the material to obtain the desired final output. Materials like wood, ceramic, glass, iron, and plastic are generally cut using machining. It uses controlled addition of material and is called subtractive manufacturing. It aims at converting raw material and scrap into useful products for production.

Machining is the most common way of creating parts in the metal industry. Different types of machining can be used in different circumstances. For example:

- Turning is used to create objects with circular cross-sections.

- Lathe machining is used to make parts with cylindrical surfaces.

- Mill machining is used to make parts with flat surfaces or made up of two parallel planes.

What is Fabrication?

Fabrication is a term that covers a lot of different types of manufacturing processes. In short, fabrication is a process wherein a material undergoes a series of steps to produce a final manufactured part. The fabrication process can be as simple as cutting a shape from a piece of metal or as complex as using a combination of metal, plastic, and wood to make a chair.

A lot of human labor goes into fabrication and the place where this is done is called a fab shop. Sheet metal fabrication is a series of processes used to turn metal sheets into useful products. Many types of metal can be used in metal fabrication, including stainless steel, carbon steel, aluminum, and brass. Metal fabricators use various types of equipment and tools to complete the fabrication process. Some of these tools include:

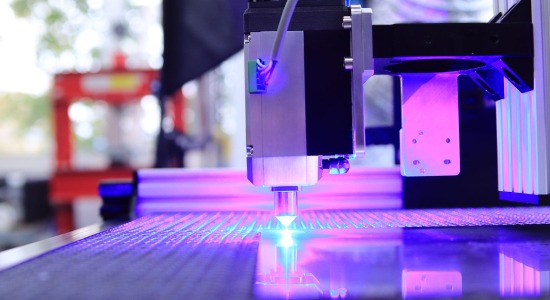

- Laser Cutters

- Benders

- Brakes

- Shears

- Metal-cutting saws

What Is the Difference Between CNC Machining and Sheet Metal Fabrication?

Daniel Smyth

Daniel Smyth There are some differences between CNC (Computer Numerical Control) manufacturing and sheet metal fabrication. CNC mills are used to create metal parts from bars rather than sheets and hence, they are difficult to make using other methods. Further, CNC machines, tabletop milling machines, and tabletop CNC are more expensive in comparison to conventional fabricating machines, but they are also highly accurate and customized to fit your needs. Besides, these machines are not as expensive as laser cutting equipment and press breaks which could cost you a fortune to achieve the same precision.

It is usually possible to make more complex designs on CNC machines than on sheet metal machines. CNC machines are more expensive than conventional sheet metal machines. But given that a CNC machine can be operated for longer, has low set up costs, and requires fewer operators, one could say that it is a cost-effective investment.

How to Choose Between CNC Machining vs. Sheet Metal Fabrication?

CNC manufacturing and metal fabrication both play a significant role in creating and designing cutting-edge components and systems. One of the most important things to consider when choosing between the two processes is the complexity of the design and its material. Sheet metal fabrication is great for complex designs and repeating shapes and patterns, but CNC manufacturing is better for complicated curves and contours.

CNC machining allows for quick turnaround, low minimums, and customization. As they are fully automated, there is very little scope for human error and a higher rate of accuracy in the output.

What Are the Advantages of CNC Manufacturing?

Opt Lasers

Opt LasersCNC manufacturing has an array of advantages over sheet metal fabrication. Besides providing an accurate finish, it also consumes less time and is safe to operate. Therefore it is more reliable than fabrication.

Another added advantage is the strength of the material. If you wish to make some intricate designs, you could carve them with your CNC machine. For instance, you could carve out the world map on wood. You could get the details on every continent, ocean, and island perfectly when using a CNC machine. That is not something you can do with sheet metal because there are stresses in the material and little to no scope for automation.

In other words, if you're looking to make a part with a very specific shape, CNC manufacturing is the way to go!

The Costs of CNC Manufacturing Vs. Sheet Metal Fabrication

With the recent technological advances in CNC manufacturing, has the cost gone down? Is it now more affordable to buy a manufactured part instead of fabricating your own? The answer is yes. The savings are substantial. There are several factors to consider when determining if CNC is the right option.

While CNC is expensive, it also has numerous benefits. There are many factors that you can take into account while making this decision. Firstly, the precision of the machining is excellent. This made it the obvious choice for high-quality products. Secondly, the comprehensive testing that can be performed on CNC machining machines ensures top quality every time.

This is essential if you are looking for consistent quality products. Besides that, it also has other benefits that come with this kind of technology, like the high volume of tasks that can be accomplished and the elimination of different kinds of errors that could result in wastage of material, rework, high costs, wasted man-hours, etc., which occurs when one uses fabrication or other methods. In other words, CNC is more economical for prototyping, odd-shaped parts that are hard to fabricate. If you need high-quality, long-term use, and little to no human intervention, CNC is the way to go.

In Conclusion

Daniel Smyth

Daniel SmythMore and more businesses are turning to CNC manufacturing for several reasons. Sheet metal fabrication requires a massive setup, numerous machinery, and ample training for the workforce. CNC on the other hand is just one piece of equipment that is seamless to use and could be operated for longer hours without increasing the costs exponentially. CNC machines are very precise, producing parts with a higher quality finish.

When it comes to producing your product (whether it's a prototype or a small batch run), you should decide which route to take based on the type of design you have. If you have a design that can be CNC machined, then CNC machining is an ideal option for you, or else sheet metal fabrication is the way to go.

What is your design? What are you looking to produce? We hope this blog post has helped you learn the differences between CNC manufacturing and sheet metal fabrication and let you make an informed decision. If you have any questions or queries on CNC Machining, don't forget to drop them in the comments section.