The International Fire Code (IFC) requires periodic testing of life safety dampers and smoke control systems. There are some state or local variations, but the requirements are essentially the same in all of the U.S.

- i International Fire Code 2018, International Code Council, Inc. (ICC), Country Club Hills, IL 60478-5795 Chapter 7 of the IFC covers fire-resistance-rated construction and where dampers must be installed in firewalls, barriers, and partitions or in smoke barriers and partitions. These dampers are for containment as part of structural compartmentation. The testing requirements for these dampers are given in Sections 703.1.2 and 703.1.3 of the IFC, which refers to NFPA 80for fire dampers and NFPA 105for smoke dampers.

- ii NFPA 80 Standard for Fire Doors and Other Opening Protectives, 2013 Edition, National Fire Protection Association, ibid.

- iii NFPA 105 Standard for the Installation of Smoke Door Assemblies and Other Opening Protectives, 2013 Edition, National Fire Protection Association, 1 Batterymarch Park, Quincy, MA 02169-7471

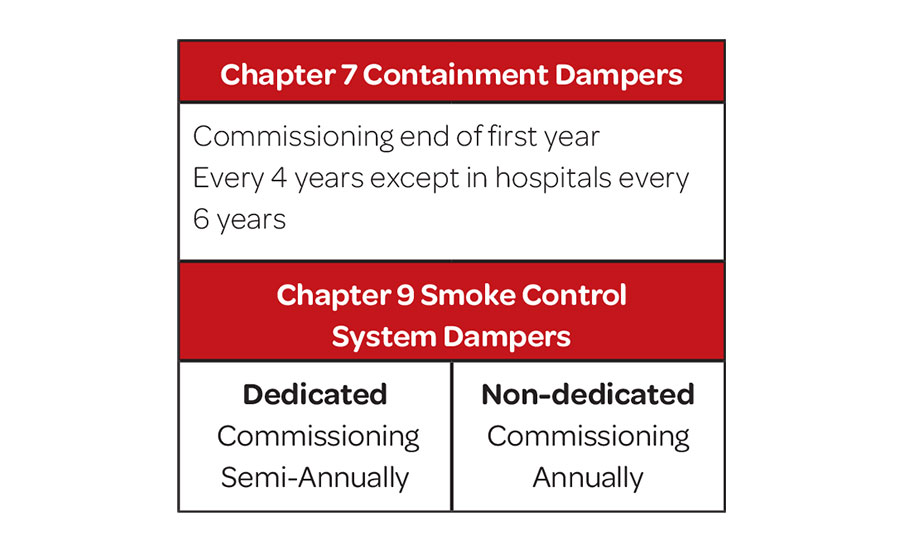

NFPA 80 Sections 19.4.1 and 19.4.1.1 and NFPA 105 Sections 6.5.2.1 and 6.5.2.2 and state the periodic requirements: inspect and test life safety dampers one year after installation, then every four years; in hospitals, every six years. This sets the periodic testing requirements for dampers installed under Chapter 7.

Chapter 9 of the IFC covers installation of smoke control systems. Section 909.18 of the IFC defines the testing requirements for initial acceptance testing of smoke control systems. Section 909.19 states that a written maintenance program must be submitted and approved before occupancy. The periodic testing requirements are in Section 909.20. Dedicated systems must be tested semiannually and non-dedicated systems tested annually. Section 909.20.3 of the IFC does state specifically that dampers are included in the smoke control system testing.

Thus, the requirements for smoke control system dampers are more stringent than those for containment. (Table 1 contains a summary of the periodic testing requirements.)

Table 1 Periodic testing requirements for dampers

Damper types

There are multiple types of life safety dampers. Most fire dampers have fusible links that melt at 165°F (74°C); these are curtain dampers and a small percentage of multi-blade types. Actuated fire dampers are available but rather rare.

Smoke dampers do not have a high temperature limit as they are controlled from a smoke detector or relay from the fire alarm system with area smoke detectors. They are always actuated.

Combination fire and smoke dampers have temperature limits and are actuated. They are not able to be reopened without pressing a manual reset button. Almost all use a bimetal to cut power to the actuator to close. (Figure 1 shows examples of a curtain damper and a combination fire and smoke damper.)

Smoke control system dampers

Only actuated smoke dampers or combination dampers are used in Chapter 9 applications. They are of the same construction as containment dampers but the controls are more sophisticated.

These dampers have either blade or actuator position indication switches that are connected to the firefighters’ smoke control panel, usually via the fire alarm system. In addition, there are override switches on a control panel that allow an incident commander to open or close the damper manually. (Figure 2 shows a hard-wired switch and position indication application.)

Figure 2 Smoke damper with firefighters’ switch and position indication

Owner responsibility

It is the building owner’s responsibility to maintain life safety dampers. Any deficiencies observed by a sheet metal contractor should be noted on a service ticket or report. Owners are frequently unaware of their periodic testing requirements as building officials and fire marshals do not always enforce the code.

This story originally appeared in the October 2019 issue of SNIPS magazine.