The average U.S. automobile has a life span of approximately eight years or 150,000 miles. Well-built, luxury vehicles may run for 15 years and/or 300,000 miles with meticulous maintenance. Despite these prognostications, there’s no way to pinpoint exactly how long a car will remain trouble-free, but, somewhere down the road, even with the best maintenance, a major component is bound to fail.

The same can be said about building controls. Despite how well manicured a facility’s building automation system (BAS) or building management system (BMS) is, it’s eventually going to break down. And after several years, even if it’s still ticking, it’s most likely unable to pair/work with new technologies.

Upgrading a commercial control system can be quite an endeavor. Numerous barriers, including cost, the need for additional infrastructure, added expertise, cybersecurity, etc., stand in the way. But much like drivers who upgrade their vehicles, those who’ve upgraded their equipment are rewarded in the form of more sophisticated control, cost savings through autonomous operation, and a more attractive aesthetic.

As an HVAC contractor, the challenge lies in distinguishing precisely when a controls upgrade is necessary, convincing the operations manager why such an investment must be made, and demonstrating that the expense is worth the reward.

The Time Has Come

Much like automobiles, HVAC controls don’t last forever.

“Even the most advanced HVAC systems aren’t expected to last more than 20 years,” said Patrick Pease, P.E., LEED AP BD+C, mechanical engineering director, cove.tool. “That's especially true for control systems, which have evolved exponentially over the last several years. If a controller has been in use for more than 20 years, it's probably time for an upgrade.”

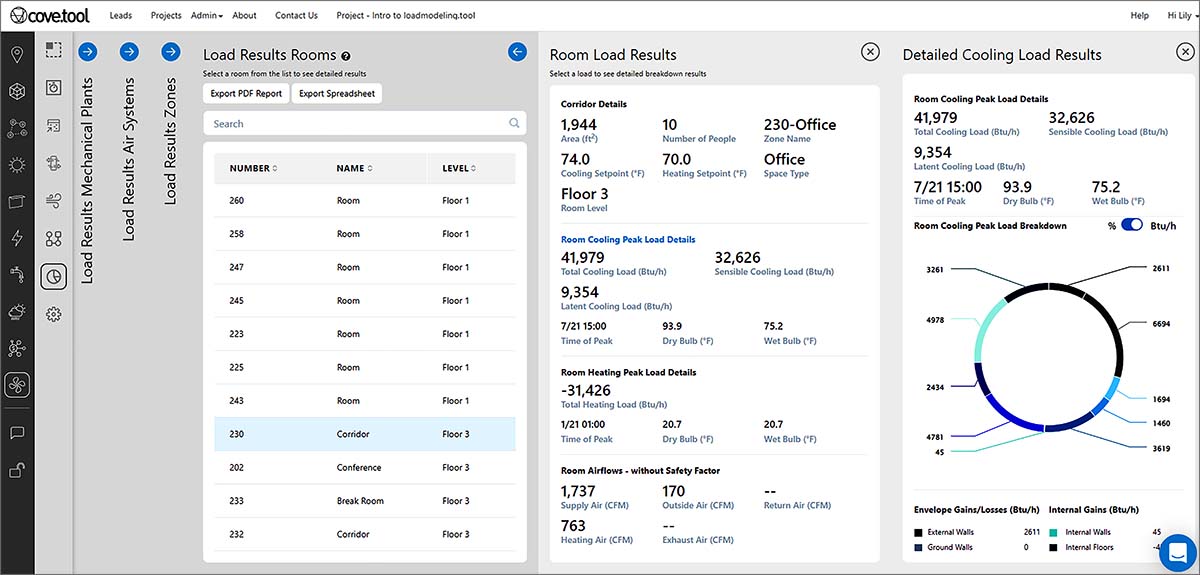

CONTRACTOR CALCULATIONS: The loadmodeling.tool from cove.tool was built to address a myriad of common pain points in mechanical engineers’ daily workflows. The tool solves issues of accessibility, repeatability, speed, and accuracy of calculating mechanical heating and cool loads. (Courtesy of cove.tool)

As equipment reaches the end of its life cycle, oftentimes, replacement parts are unavailable, which forces contractors to push for a full system replacement simply because it’s the only option.

“While controllers can last a long time, replacement units with the same capabilities, form factors, or hardware may not be available as manufacturers evolve their systems and the commercial electronics market phases out old components,” said Todd Lash, head of building automation solutions, Siemens Smart Infrastructure USA. “Additionally, older models tend to have limited functionality and are unable to support rapidly evolving applications and code requirements.”

Approximately 50% of buildings that exist today were built before 1980. Unfortunately, yesterday’s technology and infrastructure wasn’t designed to meet today’s challenges, said James Mylett, senior vice president, U.S. digital buildings, Schneider Electric.

ECOSTRUXURE: Schneider Electric’s EcoStruxure family of controls products are open and highly interoperable, and when properly installed and commissioned, the EcoStruxure Building Operation software and hardware offers a comprehensive, flexible, and user-friendly solution that enhances customers sustainability and efficiency goals. (Courtesy of Schneider Electric)

“The experience building occupants expect from their buildings has dramatically shifted over the past decade and further accelerated as we moved through the global pandemic,” Mylett said. “Most notably, expectations around resiliency, efficiency, sustainability, and people centricity are now at a point where legacy control systems, especially where those systems are non-IP, aren’t equipped to provide the outcomes building occupants require today.”

If a building control is the brains of the building, why wouldn’t you aim to make your building as intelligent as possible, questioned Mike Keller, North America building sales director, Honeywell.

“The brain directs all parts of the body to communicate with one another and tells them what to do,” he said. “The current trend for contractors is to migrate to IP-based controllers for this nervous system to make it communicate more efficiently. As with any digital experience, moving to an IP-based system provides faster, more reliable communication between controllers, which, in turn, allows faster, more accurate decision-making for building owners and increased uptime for the facility. That data reliability and speed enables better data flow to the cloud.”

Cost and Other Impediments

While the idea of owning a Ferrari is attractive to many, most Americans are unable to do so solely based on cost. When it comes to upgrading building controls, in addition to cost, there are many barriers keeping owners from taking the plunge.

“Obstacles exist, including lack of funding, lack of perceived value, and wanting to avoid perceived risks, among others,” said Chris Lane, director of product management for BAS products at Johnson Controls. “Our systems are designed for upgrade flexibility so that contractors can work with customers to implement upgrade plans that are paced appropriately. It’s more cost-effective to regularly ensure system components are working than to face sudden unplanned downtime.”

When it comes to retrofitting to an IP-based controller, one of the major drawbacks is the electrical installation cost.

“Running new Ethernet cable throughout the facility is expensive,” said Keller. “Honeywell’s new controller platform can utilize a proven Ethernet communication protocol called 10BASE-T1L. T1L technology enables Ethernet communication via a single, balanced twisted pair, which gives a contractor the option to reuse existing cable for a retrofit or run new twisted-pair cable instead of a CAT 5/6 cable, thereby reducing installation costs. In addition, T1L technology provides 10 MB per second speed, enabling a high-capacity, low-cost wired solution.”

While a controls upgrade may be costly, the reality is, the longer you wait, the more expensive a replacement can be.

“If the building is operating with 30-year-old controls, almost all of the components will need to be replaced,” said Pease. “Now you’re not just upgrading a few sensors here and there, some wiring — you might have to be ripping everything out of the building and putting it back in, [and] that becomes very challenging. That's more of a whole building renew at that point.”

mechanical engineering director, cove.tool

Solutions

When contractors are ready to specify a new HVAC controls system, manufacturers are ready with affordable, easy-to-install systems.

“Contractors want to win the work, though they’re not looking to spend a lot of money to win the work,” said Pease. “Cove.tool’s software allows contractors to formulate all the information they need to pitch the need for a control replacement. We demonstrate the value versus the cost of a controls upgrade in a digestible way that’s legible to a client in 10 minutes.”

Siemens has introduced a new range of controllers to optimize building performance for all building sizes. This includes the Climatix series with the Title 24 Economizer controller and rooftop unit optimization controller.

“Most buildings use RTUs, and the Climatix RT is a pre-programmed controller that is simple for contractors to install and configure,” said Lash. “It’s designed to improve RTU energy savings and IAQ for both old and new units. The commissioning process uses a wizard-based design that simplifies the labor required at the job site and provides access to real-time remote monitoring, ultimately reducing unnecessary truck rolls for service support.”

Schneider Electric’s Insight Sensor is capable of capturing traditional room space measurements, such as temperature and humidity, and can collect data on lighting, noise, and occupancy, which are critical metrics for people-centric building environments, said Mylett.

“By seamlessly connecting to IP-enabled room controllers, the Insight Sensor provides rich data flow and enables smarter performance for room controls, occupant comfort, and overall building efficiency," he said.

FACILITY EXPLORER: Johnson Controls’ Facility Explorer supervisory family software release 14.11.4 is enhanced with modern, 3D photorealistic graphics to help users navigate their Facility Explorer system quickly and easily. (Courtesy of Johnson Controls)

Johnson Controls’ latest innovations include the Facility Explorer supervisory family software release 14.11.4 and the Metasys Release 12.0. The software is designed to speed issue identification and resolution, prevent unauthorized access, maximize system performance, and reduce installation time and costs. New controller models and security enhancements help contractors identify and solve issues in the field, as well as maintain the latest IT security and networking standards (like BACnet/SC) and control room pressure, air changes, humidity, and temperature faster and with more accuracy.

“The latest Facility Explorer software is enhanced with modern, 3D photorealistic graphics to help users navigate their system quickly and easily,” said Lane. “It makes designing, installing, commissioning, and maintaining critical environments easier and more efficient.”

Honeywell’s Optimizer Suite consists of a variable air volume (VAV) controller, a unitary controller, and an advanced plant controller. It enables efficient installation and commissioning for contractors, cybersecurity protection, energy management, maintainability, and system operability.

REMOTE BUILDING MANAGER: Honeywell’s Remote Building Manager cloud-based supervisory software allows users to add or remove sites and capabilities at any time based on the overall level of service needed and may be used in any type of building, from leased or owned to new construction or legacy. (Courtesy of Honeywell Building Technologies)

“The solution can help give any existing building control system the same advantages of IP control as a new state-of-the-art facility,” said Keller. “Contractors can wire the new controllers into a system, connect them wirelessly, or utilize IP over twisted pair communications with T1L technology in order to transmit HVAC data.”

Another new innovation, the Honeywell Remote Building Manager, is designed to help monitor a building’s energy use and monitor operational costs. The unit allows owners and tenants to manage a building’s systems 24/7 from anywhere and on a variety of devices.

“For use in any type of building, from leased or owned to new construction or legacy, the cloud-based supervisory software allows users to add or remove sites and capabilities at any time based on the overall level of service needed,” Keller said. “Contractors can install and configure the solution in hours instead of days, as it requires minimal hardware and on-site IT support.”