The Packaged Refrigeration System is a self-contained refrigeration system for walk-in coolers and freezers. (Courtesy of Heat Transfer Products Group)

The Gold award in the Refrigeration and Ice Machines category goes to the Packaged Refrigeration System, HPO and HPH Series, from Heat Transfer Products Group (HTPG). The Packaged Refrigeration System is a self-contained refrigeration system for walk-in coolers and freezers that eliminates several of the steps required for a traditional system. In many applications, it simply needs to be hooked up to power and have the initial set points adjusted to its particular application to start cooling the environment.

“The new Packaged Refrigeration System utilizes our EcoNet technology to precisely maintain system efficiency, optimize compressor runtime, eliminate unnecessary defrost, and reduce temperature fluctuation to protect product integrity,” said Raleigh Thompson, senior marketing manager at HTPG. “Additionally, the Packaged Refrigeration System can be paired with our Command Center display so system status can be viewed outside of the walk-in.”

In order to allow one model to serve multiple applications, the Packaged Refrigeration System was designed to have a wide range of applications and option flexibility. This design also maximizes the room inside of the product, which gives the technician easier access to the components for simple servicing along with an increased number of service panels compared to other systems.

“Our equipment is designed with the future in mind,” said Thompson. “We strive to incorporate sustainable solutions along with options and functionality that satisfy regulatory compliance. The Packaged Refrigeration System is easy to install and service. It’s everything you need in one box.”

The system is also visually appealing, according to one of the contractor judges, who noted in his comments that “this is a very attractive unit. I like the easy access control panel and the removable top.”

The Packaged Refrigeration System comes in eight scroll compressor models and two hermetic compressor models. It was primarily designed for food service cooler and freezer applications but can be used in other walk-in cooler applications between 4,790 and 15,830 Btuh and other walk-in freezer applications between 3,790 and 15,130 Btuh.

Three years of research went into the Packaged Refrigeration System, with HTPG utilizing a series of formal and observational research sessions with installers and end users. During the product development process, HTPG made a conscious effort to capture feedback from contractors and technicians throughout several stages of the process.

“Specifically, we hold design reviews, teardowns, and observational research during installations with both contractors and technicians,” said Thompson. “These methods allow us to not only capture feedback on our designs from those who are installing or doing maintenance on our products, but it also allows us to solve [problems] for areas that may be more cumbersome than it should be with other designs. For example, the final Packaged Refrigeration System demonstrates the integration of feedback through the inclusion of features such as heaters that can be accessed without the need to remove a drain pan, easily removable electrical panel doors, and expanded service panels.”

Future plans for the Packaged Refrigeration System are to continue to improve controls solutions to optimize performance as well as the technician’s experience with the product. Additionally, the company is planning to incorporate lower-GWP refrigerants into this product’s offering.

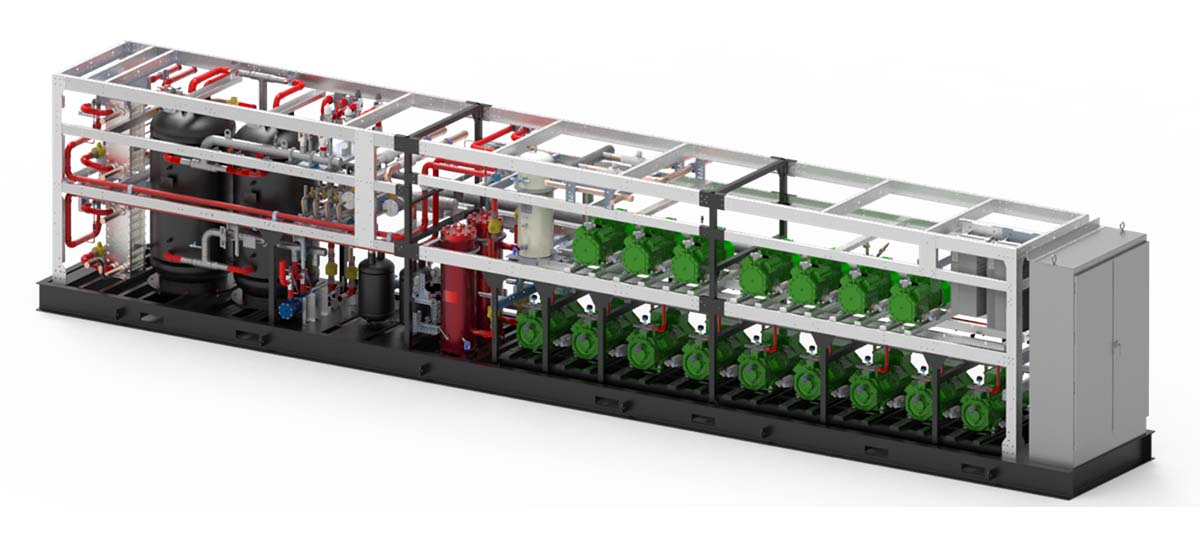

EXPANDED CAPACITY: Heatcraft Refrigeration’s eCO2Boost Transcritical Booster System offers newly expanded capacity of up to 250 refrigerated tons. (Courtesy of Heatcraft Refrigeration Products)

The Silver award goes to Heatcraft Refrigeration’s eCO2Boost Transcritical Booster System, which offers newly expanded capacity of up to 250 refrigerated tons. The system has parallel compression, which improves efficiency in warmer climates, and features a welded steel structure, which provides a higher level of quality than a bolted-together frame. The frame can be customized to benefit a specific customer application.

“The system uses natural, environmentally friendly, and energy-efficient CO2 refrigerant, which delivers top performance and reliability,” said David Bolaños, head of product management for Heatcraft. “Compared to traditional HFC systems, the typical eCO2Boost Transcritical Booster System is expected to cause 98% less global warming impact with an energy cost 6%-10% lower and a total cost of ownership 5%-10% lower.”

CO2’s GWP of 1 will keep it insulated from regulatory phaseout in the decades to come, added Bolaños, and since it is neither flammable nor toxic, companies can feel safe knowing they’re operating with less risk.

“Although CO2 is high pressure, systems are in place to mitigate related safety concerns, ensuring it is safe to work with,” he said.

The eCO2Boost Transcritical Booster System can be customized for an array of low-GWP cold storage, manufacturing process cooling, meal preparation, food processing, and blast freezer applications. The dimensions of the rack have been updated, providing technicians with ample space for accessing service areas, and the outdoor version includes an enclosure with an awning to protect technicians from weather during installation and/or maintenance. Since all piping is iron-copper alloy, regular brazing techniques can be applied, alleviating the need for welding and making installation and/or maintenance easy.

In designing the eCO2Boost Transcritical Booster System, Heatcraft relied on customer feedback from contractors and technicians, focus group discussions with service technicians, lab testing, and element analysis. Heatcraft plans to continue to improve the system and is working to expand its temperature applications down to -150°F.