Have you ever considered the carbon footprint of a cookie or maybe your mid-afternoon latte? This is the question now being asked of many food and beverage processing companies. Accounting for 6% of total industrial emissions,i the U.S. Department of Energy (DOE) has identified food and beverage manufacturing as one of the most energy- and emissions-intensive industries in the country. As part of the DOE Industrial Decarbonization Roadmap, the Biden-Harris administration has implored the industry to increase energy efficiency, switch to low- and no-carbon fuel sources, and electrify their systems to help lower global carbon emissions.ii

Food and beverage manufacturing typically involves a combination of process heating; cooling; and temperature-controlled, energy-intensive protocols that often rely on combustion fuel-powered boilers, high-demand electrical chillers, and large water reserves. As food and beverage manufacturers seek solutions to reduce operational costs and decarbonize the brewing, baking, canning, and cooking methods necessary to ensure quality and safety, they may be surprised to find the answer in a solution that’s nearly a century old: absorption cooling.

Advancements in Absorption Chillers

Historically, absorption chiller selection was driven by the type of refrigerant used, the available heat source, and the cooling capacity required. Innovations in today’s absorption chillers have enabled a broader range of heat source compatibility and can produce sub-zero temperatures without the use of high-global warming potential (high-GWP) refrigerants or even ammonia.

Conventional absorption chillers commonly produce chilled water output around 39°F. Any lower and the risk for refrigerant freezing greatly increases. Today’s innovative chillers can reach temperatures as low as 23°, an ideal temperature for producing brine water using only a water-based refrigerant cycle. This advancement enables processing facilities to transition away from electric chillers that often yield higher operational costs and eliminate the use of ammonia-based refrigerants that can pose potential health and safety risks.

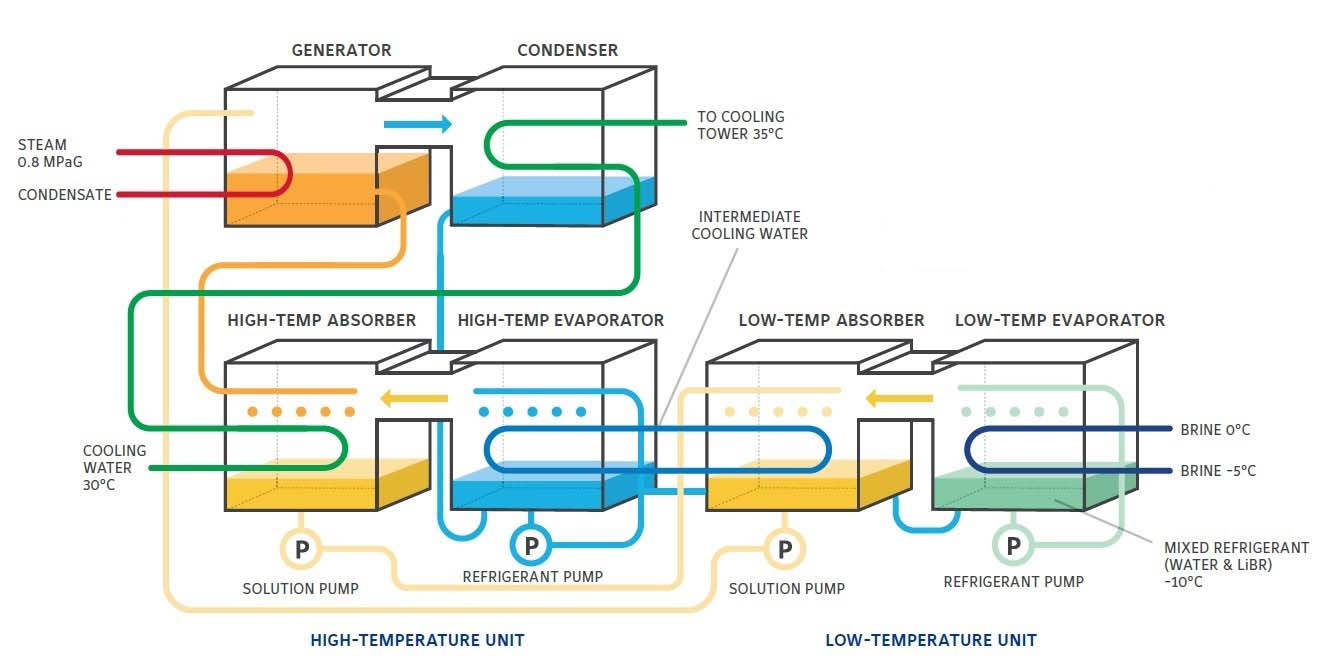

At the core of this innovation is a two-step evaporator-absorber design that integrates dual evaporators and absorbers to control the concentration of a water-lithium bromide mixed refrigerant. By splitting the absorption process into two steps, lithium bromide solution concentrations are lower in the system, enabling lower hot water temperatures within the generator, lower hot water flow rates, and the elimination of crystallization risk within the chiller. Additionally, the water-lithium bromide mixed refrigerant enables low-temperature absorption chillers to operate under a vacuum instead of under pressure — a common component of conventional ammonia-based systems. As a result, the low-temperature absorption chiller does not fall into high-pressure safety gas regulations or require a qualified operator.

Benefits to Food and Beverage

Waste heat is a common byproduct of food and beverage processing, yet this valuable energy source is often wasted. In fact, the DOE estimates that 56% of process heating energy is lost in food and beverage production processes.iii This creates a situation that can benefit from combined heat and power (CHP) systems that include a high-performance absorption chiller, a model the DOE has identified as a critical component in driving industrial decarbonization.iv

Waste heat can be harvested from a variety of sources, such as steam, co-generation exhaust, and exhaust methane gas. Although waste heat streams are often abundant within food and beverage applications, sources typically must reach temperatures of 200F or higher to effectively power boiler operation.v In contrast, advanced absorption chillers that utilize a two-step evaporator and absorber cycle can operate utilizing waste heat as low as 70F. In these systems, chilled water flows through the tubes in series through the two evaporators while the concentrated lithium-bromide solution is distributed in the absorber shell side in the opposite direction. This enhances absorption of the refrigerant into the concentrated solution, reducing solution concentrations and overall pressure.

Click diagram to enlarge

TWO-STEP EVAP: An example of a two-step evaporator and absorption chiller cycle design. (Courtesy of Johnson Controls)

Final Considerations for Absorption Chillers

Today’s low-temperature absorption chillers are more reliable and more flexible than ever before. They can be used to optimize an existing CHP system or tailored to utilize a broad range of waste heat sources, such as turbine steam or boiler exhaust gas. Because waste heat is a common byproduct of many areas of food and beverage processing, these energy-efficient systems create an ideal solution to lower operational costs and achieve decarbonization goals.

When comparing the ROI between fuel-driven or electric systems and a thermal-driven absorption chiller, it is important to consider more than COP alone to understand the complete cost-saving advantages that can be achieved. For example, local utility costs will play an integral role in determining an accurate value between electric and absorption chillers, and an absorption chiller utilizing waste heat will yield even greater cost-savings.

Low-temperature absorption chillers can also improve energy efficiency and reduce emissions by optimizing waste heat instead of consuming fuel or electricity. Additionally, modern chiller absorption designs eliminate the use of ammonia and refrigerants, providing long-term compliance as EPA regulations change rapidly. Some facility managers may find helpful resources and incentives through local and state programs designed to support industrial decarbonization which can be used to help offset initial investment costs.

- U.S. Department of Energy, Research Areas: Food and Beverage Products

- U.S. Depart of Energy, Industrial Decarbonization Roadmap (2022)

- U.S. Department of Energy, “Innovating clean energy technologies in advanced manufacturing” (2015)

- U.S. Department of Energy, “Combined heat and power technology fact sheet series” (2017)

- U.S. Environmental Protection Agency (EPA) Combined Heat and Power (CHP) Partnership (2022)