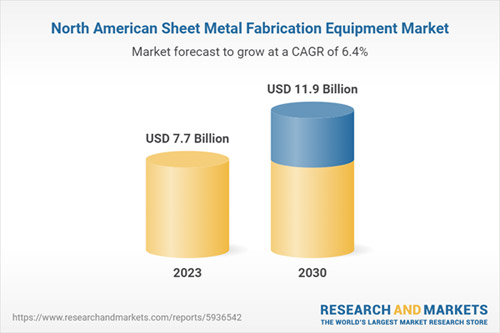

The North American sheet metal fabrication equipment market is anticipated to see significant growth, with projections estimating a market worth of USD 11.9 billion by 2030, per a new report from ResearchAndMarkets.com. The market is expected to grow at a steady compound annual growth rate (CAGR) of 6.4% from 2024 to 2030. This expansion is attributed to technological advancements and the steady increase in demand from key end-use sectors such as aerospace, construction, and automotive industries. Cutting-edge developments in metal fabrication technologies, including laser and waterjet cutting techniques, are poised to catalyze the industry's trajectory.

Influx of Innovations in Automotive Sector Fuels Demand

With relentless innovations in vehicle design and the introduction of advanced materials in the automotive sector, the requirement for sheet metal fabrication equipment is on a constant upswing. The market is receiving a substantial push from the automotive industry, which heavily relies on these equipments for the manufacturing of intricate vehicle parts and components, thereby supporting the growth of the sheet metal fabrication equipment sector in North America through the forecast period.

Impact of Urbanization and Infrastructure Development

The growth in North America's population, coupled with rapid urbanization and progressive infrastructure development, is fueling the expansion of the automobile industry. Consequently, the demand for a broad array of metal building components has been rising continuously. Modern architectural designs implemented in new building projects are increasingly demanding specialized sheet metal roofing materials and decorative panels, resulting in heightened demand for sheet metal fabrication machinery that can deliver these components with precision.

Advancements in Automated Sheet Metal Cutting Machines

Another significant factor propelling market growth is the shift towards automation and customized mass-production in various applications, leveraging advanced, mechanized sheet metal cutting machines for precision manufacturing. As legacy equipment gives way to more advanced, automated technology, this trend is expected to surge. Industries are eager to upgrade their manufacturing processes and align with evolving consumer demands by integrating state-of-the-art fabrication equipment.

Competitive Landscape and Market Initiatives

The North American market for sheet metal fabrication equipment is highly competitive, featuring many firms with sophisticated product design and development capabilities. Key market players are continually launching innovative products to cater to the dynamic requirements of end-use industries. Companies are investing heavily in research and development to secure their position in the market and to expand their share across the region.

The strength of the market is further reinforced by the segment insights, showing a particular incline towards the 'others' category, which encapsulates various processes such as drilling and stamping. Moreover, the job shops' application segment, which manufacturers components on a made-to-order basis, claimed the largest revenue share, demonstrating the market's responsiveness to customized consumer demands.

Regional Insights

The U.S. commanded the dominant market share, with substantial impacts from government endeavors in infrastructure development, booming automotive production, and increasing defense spending. Meanwhile, Mexico is anticipated to experience the most rapid growth due to its strategic manufacturing and export capability, particularly concerning automobile production. In recent developments, industry players such as AMADA CO., LTD. have introduced pioneering press brake systems that accommodate both long and diverse material workpieces, showcasing significant enhancements in operational efficiency powered by technological innovations such as AC servo motors and two-way piston pumps.

The North America sheet metal fabrication equipment market stands as a testament to the region's technological progress, aligned with the growing demand from its robust industrial sectors, signaling a strong market outlook for the years to come.

Report Attribute |

Details |

No. of Pages |

130 |

Forecast Period |

2023 - 2030 |

Estimated Market Value (USD) in 2023 |

$7.7 Billion |

Forecasted Market Value (USD) by 2030 |

$11.9 Billion |

Compound Annual Growth Rate |

6.4% |

Regions Covered |

North America |

Companies Featured

- Trumpf

- DMG Mori Co. Ltd.

- Salvagnini

- AMADA Co. Ltd.

- Coherent Corp.

- Flow International Corporation

- Koike Aronson, Inc.

- Bystronic Laser AG

- Winbro

- Mazak

- Prima Power

- Mitsubishi

- The Lincoln Electric Company

- ESAB Corporation (Colfax Corporation)

- Komatsu Industries Corp.

- WARDJet

- Omax Corporation