In the simplest terms, the HVAC industry is about moving conditioned air from one area to another.

The concept has more or less remained the same since Willis Carrier brought the first electrically-powered a/c unit onto the scene in 1902 and an early iteration of the electric fan was used to circulate that cool air.

In the 1950s, there was a central a/c system revolution and, as a result, many buildings in the United States still contain ductwork. Forced air systems are still a go-to for retrofits, and at the heart of that lies the tried-and-true air handler.

While some new construction projects are opting for ductless systems, air handlers are still holding as a viable option, especially when paired with one of the bigger stars of the HVAC scene as of late.

Market Growth

In combination with a heat pump, air handlers are seeing an uptick in market growth, driven in part by increased awareness about its sustainability factor and how well it fits into the electrification puzzle.

SMART CONTROLS: With more technology being incorporated into air handlers, contractors are finding them easier to install and troubleshoot. (Courtesy of Rheem)

“Air handlers are designed to support all of those needs when combined with heat pumps and applied to support those needs while meeting performance levels that enable the homeowner to take advantage of incentives like tax credits, utility rebates, and state incentives,” said Tony Young, senior product manager, residential air conditioning at Rheem.

Just like any other modern piece of HVAC equipment, air handlers have integrated technology that increases efficiency and ease of use.

“Both contractors and consumers have been very receptive to smart controls, particularly Rheem’s Smart Monitoring System, as it offers new levels of protection, comfort and savings,” Young said. “Consumers appreciate the ability to be alerted of system maintenance reminders, and the flexibility offered to adjust temperatures all from a mobile app while also seeing higher product efficiency and lower energy bills.”

More specifically on the installation and repair side, these smart controls allow technicians the ability to quickly diagnose issues through the air handler’s advanced monitoring capabilities, which saves valuable time and resources.

“Additionally, the smart controls allow for better comfort and IAQ,” Young noted. “Variable-speed air handlers enable longer cooling cycle run times, lowering humidity in the space and increasing comfort at a chosen temperature set point. This extended run time contributes to better IAQ as more air passes through the ducts and therefore the filter, making it more likely that particles in the space will be filtered out.”

As the industry continues to trend toward consumer demand for renewable energy, Young said they are seeing a gradual transition toward variable-speed systems, which offer higher efficiency, better dehumidification, and often much quieter operation, which greatly appeals to consumers.

As mentioned earlier, since air handlers and heat pumps often go hand-in-hand, this duo continues to gain in popularity in both new construction and even retrofits, because they help meet new energy requirements while also giving consumers the satisfaction of knowing they’ve lowered their carbon footprint.

“This is especially true for new construction projects, as many markets are starting to require heat pumps in order to achieve decarbonization goals,” Young said. “While many regions still allow gas heat installations, there is a growing focus on energy savings requirements, as part of both retrofits and new construction.”

When it comes to the big retrofit jobs, air handlers are a viable and trusted option, as the following cases show.

Everything is Bigger in Texas

The Lone Star State never does anything halfway, so when it came cooling a Texas-sized speedway, neither could Rheem.

Every race day, nearly 154,000 spectators descend upon the Texas Motor Speedway in Fort Worth to fully immerse themselves in everything NASCAR has to offer.

Regardless if visitors are shoulder-to-shoulder in the grandstand or lapping it up in one of the 200 luxury guest suites, everyone is subject to the whims of the Texas sun.

With temps regularly topping 100° in the summer, the need to replace the original cooling system installed for the track’s 1997 opening was paramount.

In the luxury suites, where select clientele expect to be able to watch the races in comfort, the existing equipment was outdated, and with one HVAC unit per suite, the cost to run and maintain the equipment was significant.

To remedy the issue, Dallas-based Mechanical Partners Inc. worked with Gemaire Distributors and the Rheem commercial air team to select more efficient heating and cooling equipment to bring to Texas Motor Speedway. Together, they upgraded the packaged rooftop HVAC units to 10-ton Renaissance packaged units, featuring factory-installed economizers and VFDs to boost overall equipment efficiency.

“One of the things that I like that they do for us, and other manufacturers don’t do, is that the economizers are factory-installed,” said John Blackall, director of service at Mechanical Partners. “That saves me one to one-and-a-half hours on install. In general, they are easy to install and service because you have easy access to everything through the side panel. And on an install like this, time is money.”

In an arena where everything is expected to move fast, the cleanup after such a big project wasn’t going to be given an exemption. With race day looming, the old equipment needed to be lifted off the speedway’s roof and replaced by new units with help from a helicopter — a huge undertaking yet the most efficient. But if anyone knew what it would take to pull off an install as big as this one, it was the Mechanical Partners and Gemaire teams.

“There’s no room for error on a project like this,” said Derek Black, commercial specialist at Gemaire. “The success of this installation is due in huge part to the partnership between all those involved. It’s all about building relationships and gaining trust.”

Once the replacement equipment hit the roof, the Mechanical Partners team quickly moved in to connect and commission the units. Thanks to months of preparation and hard work, the units were quickly and successfully up and running just in time for a packed house on a triple-digit day.

The culmination of years of research and development, the Rheem Commercial Renaissance Line was crafted with smart new features and exclusive PlusOne advantages for easy replacement, installation, and service. PlusOne ServiceSmart features such as the Qwik-clean drain pan and Qwik-change flex-fit filter rack will help make routine maintenance easier and faster, and the higher efficiency features will keep Texas Motor Speedway’s guests comfortable for years to come.

“We just replaced 19 of the air conditioning units,” said Mark Faber, executive vice president and general manager at Texas Motor Speedway. “Eventually we’ll replace 150 over a several-year period.”

Protecting a Pair of Presidents

When it comes to important historical documents, there is no room for comprise on the quality of HVAC equipment.

At the Fred W. Smith National Library for the Study of George Washington, located at George Washington’s Mount Vernon, the facility acts as the safeguard for the founding father’s books, manuscripts, and related papers, as well as serving as an arena that provides educational outreach and scholarly residency programs.

WASHINGTON'S NEW FACILITY: The 45,000-square-foot Fred W. Smith National Library had a variety of needs room-to-room, which a new air handler was able to handle. (Courtesy of Carrier)

The 45,000-square-foot facility was set to contain a host of unique areas, including the Reading Room, Rare Books Vault, Rubenstein Leadership Hall, and DeVos House Scholars’ Residence, as well as classrooms and supporting offices — all with differing indoor air quality needs.

When the Mount Vernon Ladies Association, a private nonprofit organization that owns and operates the historic property, began its design process, they knew the library would require a state-of-the-art HVAC system in order to protect the approximately 1,500 18th- and 19th-century books and papers included in the collection. They also wanted an efficient solution that would meet the diverse needs of those different areas of the new library.

To accomplish this task, the Association reached out to Carrier to assist in the development of the HVAC system for the library. With specialized experience in the historic buildings arena, Carrier opted to go with its 45-ton AquaSnap 30MPW heat recovery chiller and three Carrier Aero 39MN air handlers.

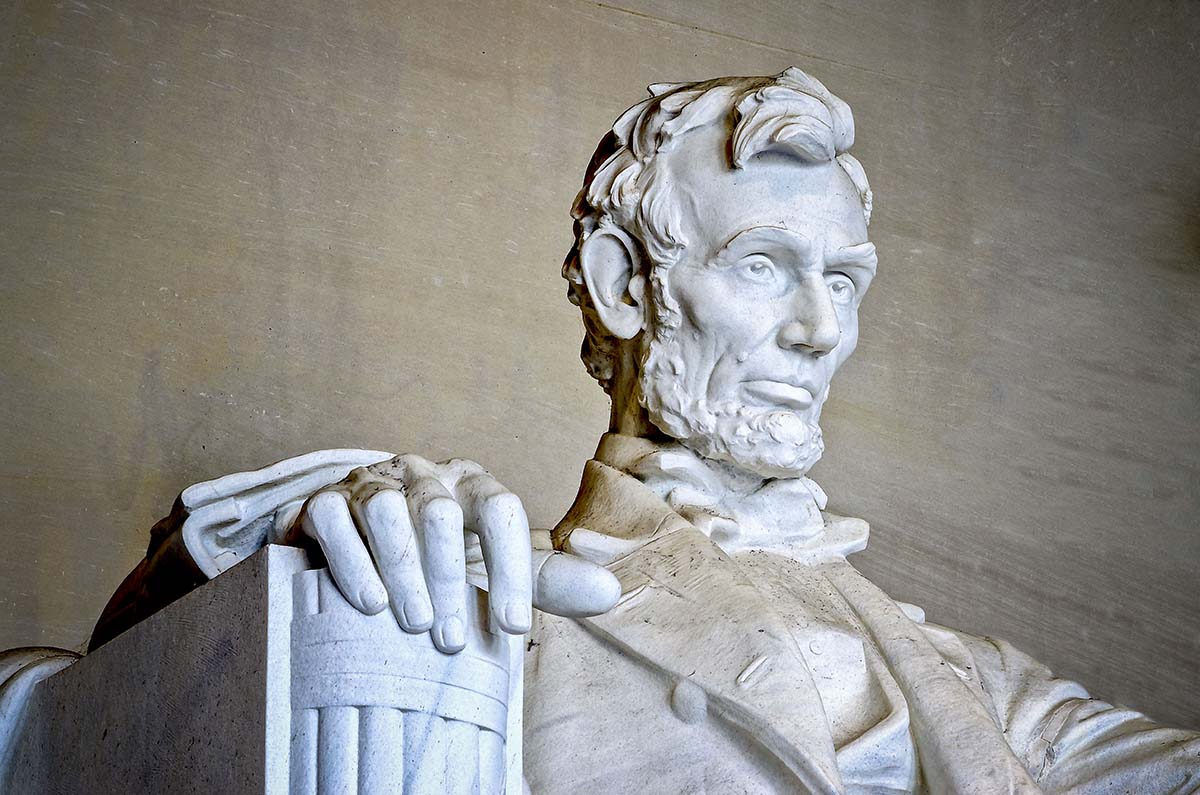

THE GENERAL’S LIBRARY: In order to protect the important documents of the nation’s first president, the folks at the Fred W. Smith National Library for the Study of George Washington went with an air handler for its project. (Courtesy of Getty Images)

STAR OF THE SHOW: Carrier’s Aero 39M air handler serves as the heart of a pair of HVAC systems that protect the personal effects of Presidents Washington and Lincoln. (Courtsy of Carrier)

“The AquaSnap 30MPW chiller enhances energy efficiency and lowers utility costs by redirecting heat from the dry cooler to the facility’s heating loop,” said Vincent Gusmano, senior sales engineer at Carrier. “When it’s winter outside, yet indoor occupancy conditions demand air conditioning for humidity control, the AquaSnap chiller captures the waste heat from the cooling system to deliver economical occupant comfort.”

The 39MN air handlers were an indoor installation — a necessity for historic properties where maintaining original exterior appearance is essential. They are ideally suited to special installations because they can be customized with several filtration options and ultraviolet B and C germicidal lamps according to specific facility requirements. One of the 39MN air handlers at the Washington Library integrated carbon filters to remove any gases that might damage the rare books, while standard filtration units cool common areas of the library, such as the classrooms and lecture hall. The 39MN air handlers were also well suited to this project because of their reliability, quiet operation, and ease of maintenance.

“We are very pleased with our Carrier equipment,” Joe Sliger, vice president, Operations & Maintenance at George Washington’s Mount Vernon, said. “The reheat chiller in the library complex was a new concept for us, but we have been amazed by its great performance and efficiency.”

Jumping from the one-dollar bill to the five and a new build to a retrofit situation, Carrier also found itself charged with protecting and preserving the priceless artifacts from another of the nation’s most recognized faces, Abraham Lincoln.

With a mission to preserve, protect, and interpret the house where Lincoln and his family lived in Springfield, Ill., for 17 years prior to his election to the presidency, the Lincoln Home National Historic Site needed an upgrade.

THE GREAT EMANCIPATOR: At the Lincoln Home National Historic Site, an air handler was used to retrofit an outdated system. (Courtesy of Carrier)

With more than 200,000 visitors moving through the facility every year, the site provides an educational experience about the relevance of Lincoln’s life to people living today, in addition to preserving numerous historical furnishings and artifacts associated with his life.

With the home striving for historical accuracy and a sense of the period-appropriate appearance of an 1860s residence, the addition of air conditioning needed to be handled with care.

Given Willis Carrier did not invent modern air conditioning until 1902, about 37 after Lincoln’s assassination by John Wilkes Booth at Ford’s Theatre, the original Carrier HVAC system at the home was cleverly concealed to provide appropriate conditions while hiding any traces of the modern air delivery system, which is located in the security railings.

However, with that existing system having been in service for 25 years, much longer than its expected lifespan, it was time for an upgrade.

HISTORIC RETROFIT: At the home of Abraham Lincoln, a new air handler was able to breathe life into an old, outdated system. (Courtesy of Getty Images)

The National Park Service, which manages the Lincoln Home site, called on Henson Robinson, a Springfield-based Carrier contractor, to tackle this important task.

“The project was important to the Lincoln Home National Historical Site because it allowed us to accomplish one of our primary goals, which is the long-term protection of the Lincoln Home and its contents for future generations,” said Dale Phillips, superintendent at the site.

Throughout the project, the folks at Henson Robinson were able to keep the facility open to the public while the necessary renovations were taking place.

“It was an interesting challenge to perform this installation with a minimum of disruption to the visitors and staff. The components of the air handler had to be delivered through a standard three-foot-wide door, and we could not so much as drill a hole without permission from the staff,” said Mark Patrick, project manager for Henson Robinson. “However, the project was very successful, and we believe our founder, Henson Robinson — who himself was a neighbor of Lincoln’s and provided cutlery for the Union Army during the Civil War — would have been proud.”

Working in the basement and yard, Henson Robinson disassembled and removed the old HVAC equipment and replaced it with a Carrier AquaSnap 30RA air-cooled chiller and an Aero 39M air handler. The air handler was installed in the basement of the historic home, while the chiller was placed in a modern but period-designed outbuilding that also serves as a warehouse for artifacts not currently needed for display. The buried coolant loop that connected the original chiller and air handler was also updated, necessitating the services of an archaeologist to oversee the digging in the yard, in case the contractors found any historical objects.

The Aero 39MN air handler includes an electric heater, so the unit is able to provide both heating and cooling to the Lincoln Home. In an interesting adaptation, fresh air enters the system via dampers in an old chimney. Two dehumidifiers and a steam-powered humidifier serve to keep the relative humidity at the target 50%, ideal for both human health and artifact preservation. In the hot and humid summer months typical of Springfield, the AquaSnap 30RA chiller provides additional cooling capacity by sending chilled water to the air handler via the loop buried under the yard.