As mildly flammable (A2L) refrigerants begin to enter the marketplace, ensuring the safety of technicians and end users is becoming even more critical. For that reason, manufacturers are equipping their comfort cooling systems with special features in accordance with safety standard UL 60335-2-40. One such feature is the refrigerant detection system (RDS), which will be required for A2L systems in occupied spaces exceeding a specific refrigerant charge limit.

At the recent HVAC Excellence National HVACR Education Conference in Las Vegas, Nevada, Chris Forth, vice president of regulatory, codes, and environmental affairs at Johnson Controls, shed light on the pivotal role that RDSs will play in the new A2L units.

Vice president of regulatory, codes, and environmental affairs

Johnson Controls

How It Works

The RDS is a stationary device that is installed in an HVAC system and designed to identify a specific refrigerant at a predetermined concentration threshold, prompting the initiation of one or more mitigation measures by the equipment. Although there are various types of RDSs, they operate on a similar principle. Typically, the RDS incorporates a sensing element, which is sensitive to the specific refrigerant gas in the system. In the event of a significant A2L leak, the sensor's signal is relayed to the mitigation control board. If the refrigerant concentration surpasses the pre-established threshold, the RDS signals the HVAC equipment to activate mitigation measures, such as turning on fans and blowers to reduce the refrigerant concentration to a level well below the flammability limit.

1

SENSOR SIGNAL: In the event of an A2L leak, the sensor (1) will signal the control board to activate mitigation measures. (Staff photo)

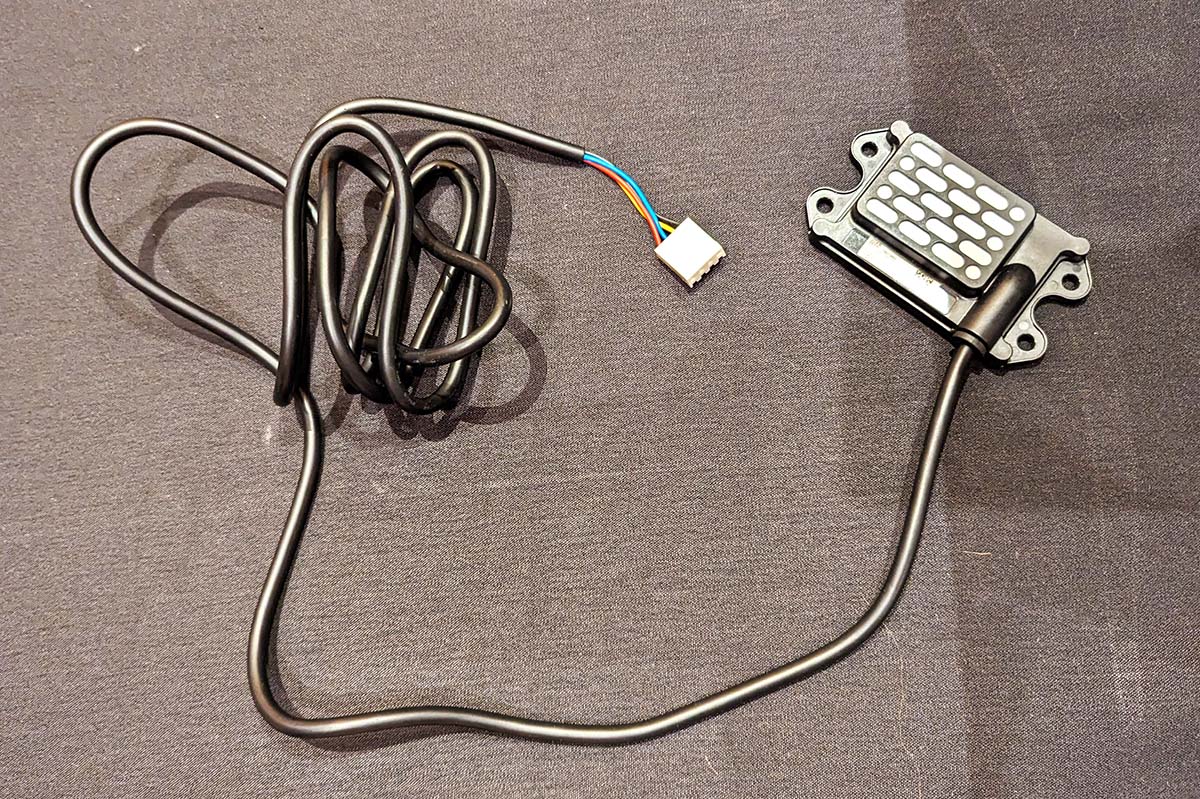

CONTROL BOARD: The RDS control board from Johnson Controls (2). (Staff photo)

2

“The RDS function is to dilute any ignitable concentration of leaked A2L gas. That's its job,” said Forth. “The RDS will turn off all the unnecessary electrical loads that are not tied to airflow operation and then dilute that concentration of refrigerant. That's the goal.”

Per UL 60335-2-40, when the RDS “senses a concentration of refrigerant gas that is 25% of the lower flammability limit (LFL) for that gas, the refrigerant detection system must initiate a system response to mitigate the potential hazard.” This provides a significant safety margin, said Forth, so even if the RDS detects a concentration at 25% of the LFL, it remains well below the point of ignition — even in the presence of a suitable ignition source. It then triggers the blower to further reduce the concentration.

An RDS is not mandatory for all applications; for example, an RDS is not necessary in systems with a charge size below 4 pounds. Forth said this decision was based on thorough calculations and research and that many ductless systems and small packaged products will fall below this threshold. In systems over 4 pounds., an RDS may also not be required in certain applications, depending on the size of the room, the height of the space, charge size, etc. (check with the manufacturer for further details).

Installation Location

“An RDS can be factory or field mounted and must be 100% factory certified for that product,” said Forth. “In other words, there won’t be any generic RDS sensors that can be installed on different OEM products. That's not allowed.”

In addition, the manufacturer will specify where exactly the RDS must be installed. Forth noted that in some Johnson Controls packaged rooftop units, for example, the RDS will be located in the return air duct.

“How did we get to that location? We did a lot of testing with our safety agency,” said Forth. “And you have to look at all different modes of operation, including ‘off’ mode. In fact, one of the biggest factors was the ‘off’ mode, because we didn't want that refrigerant leaking back down into the return duct. When you simulate a leak under the different scenarios — economizer, non-economizer, cooling, heating — they look at the worst-case scenario, and the agency determines where that location is. You can’t pick it out. It's defined. If the RDS kit is installed in the field, there will not be any flexibility on where it goes or how it’s wired.”

For contractors and technicians worried about possibly mixing up the wiring when installing an RDS in the field, that’s just not possible, said Forth. “The wiring harness has a mated plug to it, and the thermostat wires to the mitigation control. Always read the OEM's instructions, because there might be different scenarios on how the RDS is wired. But the big point is, the thermostat wires to the controller — not the old board like it used to. That way, the safety controller has control of the unit.”

At Johnson Controls, Forth noted that the control board will have LEDs that use flash codes to signal any problems. For example, a solid red light will signal that an RDS control failure has occurred, while two red flashes will indicate that the sensor detects a refrigerant leak above 15% of the LFL.

“Per the UL standard, the RDS must self-test for leaks at least every hour,” said Forth. “And if the RDS fails, the blower's going to come on permanently, and there will be an error code. This is just another control, not unlike what contractors have seen before — it’s just doing a different function. This is nothing new.”

Later this year, Forth said that Johnson Controls will be releasing the RDS Calculator, which determines if and when commercial and residential products using R-454B refrigerant require an RDS — per standard UL/CSA-60335-2-40 — based on actual building applications.

“This tool takes into account the refrigerant volume, supply air discharge height, total area being conditioned, and potential individual zone impact, to determine if an RDS is required,” said Forth. “It will also determine if exhaust air is required in the conditioned space. The user-friendly calculator gives straightforward results in a couple of simple steps. This is going to be a very helpful tool for contractors.”