SAFETY FEATURES: The RAD80ELED has a built-in thermal cut-off fuse, which protects both technicians and end-users from potential hazards, such as overheating or electrical malfunctions. (Courtesy of Delta Electronics)

Winning Gold in the Ventilation Products category is the BreezRadiance RAD80ELED - 80 CFM Fan/Edge-lit Dimmable LED light with Heater, manufactured by Delta Electronics (Americas) Ltd.

The RAD80ELED is designed primarily for installation in bathrooms to provide both heating and ventilation functions.

“The DeltaBreez RAD80ELED is a cutting-edge ventilation fan with a heater that redefines comfort and functionality in your bathroom,” explained Ken Chiu, senior product manager. “Its ultra-slim profile and sleek form save valuable space, especially when ceiling-mounted.”

The fan’s heater element, with a power rating of 1300W, provides warmth during colder seasons or in regions with chilly climates. For ventilation functionality, it’s equipped with a brushless DC motor and an airflow rating of 80 CFM to remove moisture, odors, and airborne pollutants and promote IAQ, prevent the formation of mold and mildew, and reduce the risk of respiratory issues, creating a healthier living environment for occupants. It’s suitable for residential homes, hotels, resorts, and other hospitality establishments where maintaining a comfortable indoor temperature is essential.

One year of research went into the RAD80ELED’s design. Chiu said it has three features specifically designed with a technician's daily job in mind.

First, its energy-saving brushless DC motor technology ensures that the ventilation fan operates efficiently, reducing energy consumption and minimizing the need for frequent maintenance.

“Technicians benefit from this technology, as it lowers the likelihood of motor malfunctions or failures, resulting in fewer service calls and increased customer satisfaction,” he said.

For safety, it has a built-in thermal cut-off fuse, which protects both technicians and end-users from potential hazards, such as overheating or electrical malfunctions. And, the inclusion of a metal guard adds an extra layer of safety by preventing direct contact with the heating wire, reducing the risk of burns or injuries during installation or maintenance.

Chiu called the introduction of Delta ventilation fans “a milestone” in green construction and energy-efficient ventilation solutions.

“Our fans not only enhance aesthetic appeal but also consume less power while delivering advanced functionality and quiet operation compared to AC motor models,” he said. “The inclusion of energy-saving features such as the brushless DC motor and LED lighting … aligns with the HVAC industry's emphasis on sustainable practices and reducing energy consumption, thereby lowering operational costs for both homeowners and commercial property owners.”

SUPPLY FAN: The KSQ features Greenheck's Vari-Green EC direct-drive motor, offering up to and including 10 hp for highly efficient operation. (Courtesy of Greenheck)

Taking Silver is Greenheck for its KSQ Mixed Flow Supply Fan, a direct-drive untempered make-up air supply fan that incorporates a mixed flow wheel and EC motor technology to supply filtered air for kitchen systems as well as general building applications, like elevator shaft pressurization.

Designed to be mounted on a roof deck, the KSQ provides a cost-effective alternative to higher-priced tempered make-up air units with comparable performance. It also provides energy savings to the customer and helps exceed California Title 20 and anticipated Department of Energy (DOE) fan energy regulation requirements.

The KSQ features Greenheck's Vari-Green EC direct-drive motor, offering up to and including 10 hp for highly efficient operation. The Vari-Green motor and control options enable easy setup and maintenance, help optimize system performance, and lower operating costs. It also has totally enclosed direct drive motors for easy access and maintenance.

“Many products utilize open motors that are encapsulated by a difficult-to-remove motor cover,” said Nathan Fetting, segment manager. This product’s motors, however, are pre-wired to the top of the unit for ease of field wiring or future access. Additionally, the KSQ has a drop-down filter rack for easy removal of filters, and full-side access doors for better access to the wheel and motor. Maintenance-free direct drive motors also eliminate the need to replace or maintain belts.

The KSQ also has a mixed flow wheel that improves airflow and efficiency, in conjunction with housing designed around high efficiency, and allows the purchase of smaller fan packages instead of having to upsize to meet the same performance requirements.

Multiple configurations are available, including horizontal or bottom intake as well as horizontal or bottom discharge, allowing the fan to be curb-mounted or ducting to be run on the roof deck for installation flexibility. To support IAQ and reduce the load on the HVAC system, washable 1-inch aluminum filters are provided as standard. The KSQ also offers optional MERV 13 filters available in the bottom intake configuration.

“I love everything about this product,” wrote one of the contractor judges on the ACHR NEWS panel. “Fully encapsulated motor means no more doors to take off; eventually the screws are all loose/stripped and doors are hanging off or, worse, blowing off rooftops, creating a hazard for pedestrians. No belts to change means fewer 3 a.m. service calls, trips to the wholesaler, and/or fewer parts to stock on-site. Mixed flow wheel and a smaller footprint. Win, win, win.”

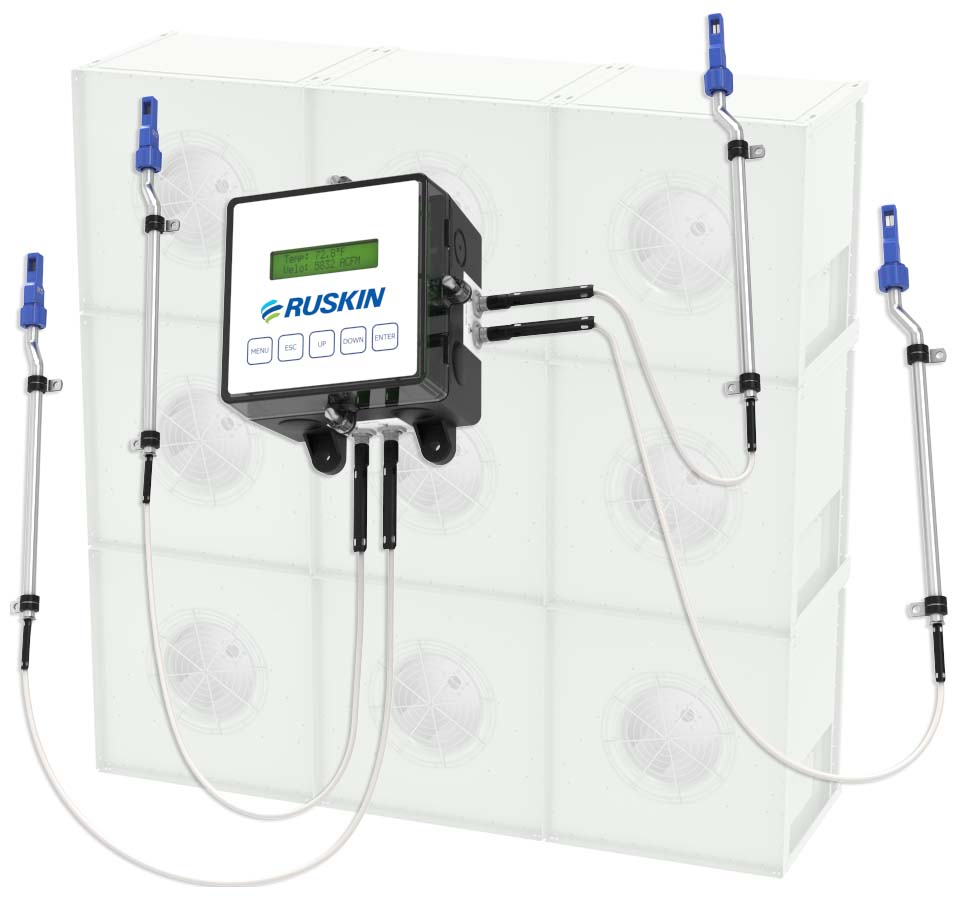

FAN ASSIST: The TDFi-FA measures both airflow rate and temperature and communicates system data to the building automation system (BAS) through analog outputs and communication protocols. (Courtesy of Ruskin)

This year’s Bronze winner, the TDFi-FA by Ruskin, is a thermal dispersion fan inlet device for fan array applications within commercial HVAC systems. Using highly accurate thermal dispersion sensing technology, the TDFi-FA measures both airflow rate and temperature and communicates system data to the building automation system (BAS) through analog outputs and communication protocols, optimizing system performance for greater efficiency while maintaining fresh air ventilation for healthy environments.

The TDFi-FA host reads data collected from up to 16 individual fans, utilizing 1 or 2 sensors per fan. This makes it possible to collect a maximum of 32 airflow and temperature values from the fan array installation. Each fan has one or two sensors located in the fan’s inlet. The sensor’s design ensures minimal pressure drop by using less hardware across the fan inlet. Each sensor has a heated and passive thermistor. The airflow and temperature information from each sensor is configured to correspond to the fan on which it is installed. This feature makes it possible to use only one host as the interface point for processing air measurement from multiple fans (of the same diameter) on one or more AHU or RTU.

The device-calculated data is communicated to the BAS, either through analog or digital communications, and is used by the BAS to control fan speeds and adjust damper positions to maintain HVAC airflow requirements. The data provided by the TDFi-FA gives systems engineers assurance that energy efficiency is optimized while proper airflow is being delivered throughout the occupied spaces.

The TDFi-FA includes standard cabling and a tool-free, one-touch setup that simplifies installation and minimizes onsite labor costs. A built-in 1-, 2- or 3-point field calibration process uses actual airflow data, which can be communicated to the BAS through BACnet MS/TP or Modbus RTU network connectivity or through convenient analog outputs.

“By unlocking critical airflow data and transmitting it to a building automation system, the TDFi-FA makes it possible to automate control fan speeds, adjust damper positions to meet HVAC airflow requirements, and ensure minimum ventilation (per industry standards) is being delivered to occupied spaces,” said John Haukap, product manager. “This solution advances the digital transformation of airflow and HVAC technology, which helps to continually optimize building health and performance.”

The TDFi-FA was developed over a year and a half, using field trials, focus studies, and customer feedback from a previous model launched in 2021.