Regulations to combat global temperature rise are driving the urgent need to move to low-GWP refrigerants. The United Nations International Panel on Climate Change (IPCC) has set ambitious targets: cutting emissions by 45% by 2030 and achieving net zero emissions by 2050. These goals are crucial to limit global temperature rise to 1.5°C above pre-industrial levels (from the 1870s to 2100), which is the critical threshold for climate change.

However, recent data indicates that we’re not on track. So, how can we course correct?

One critical factor is recognizing the role of refrigerants in the decarbonization puzzle. According to the Natural Resources Defense Council, preventing HFC refrigerant leakage can avoid 0.5°C of global temperature rise by the end of the century – a third of the total target. Addressing refrigerant choices and developing next-generation solutions becomes essential for achieving our climate goals.

New Solutions

Increasing regulations are inspiring innovation of lower-GWP solutions, and these materials must balance performance vs. GWP in new and existing system architectures. R-1234yf (YF), an A2L refrigerant with a GWP of less than one, has been introduced as a blend component for the most popular lower-GWP R-410A alternative, R-454B. As a single molecule, YF had been considered an optimal choice despite a significant performance reduction vs. R-134a, as determined by Orbia Fluor & Energy Materials thermodynamic cycle calculations and validated with external testing.

However, more sustainable applications like heat pumps are gaining popularity, while countries work toward improving their carbon footprints and minimizing the environmental impact of their products. As a result, blends are emerging as essential mechanisms to address this growing list of performance and property criteria for new refrigerants.

It is important to acknowledge the significance of blends in the context of low-GWP refrigerants. At Orbia Fluor & Energy Materials, we view R-1234ze(E) (ZE) as the new preferred backbone molecule for low-GWP, enhanced-performance blends. In fact, we are investing substantial R&D efforts into ZE as a blend component to deliver refrigerant benefits, including:

- ZE as an HFO: As an HFO, it provides an exceptionally low atmospheric lifetime — around 16 days — while maintaining high stability in operation.

- Versatile applications: ZE is currently used in multiple applications today, including chillers and heat pumps in addition to medical use cases.

- Minimal TFA: 2 ± 2% of R-1234ze(E) decomposes into trifluoroacetic acid (TFA), which is a material being targeted for regulation in the European Union (EU): 100% of the incumbent, R-1234yf, decomposes into TFA.

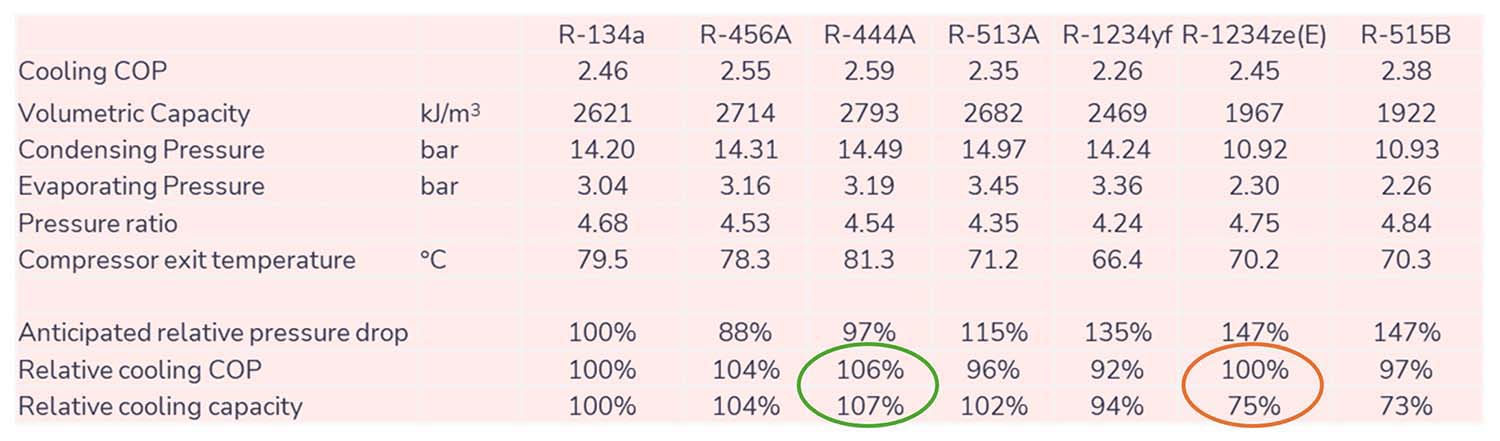

- Capacity consideration: As a single molecule, R-1234ze capacity may not be sufficient for some applications (orange highlight in Table 1) as a drop-in, but changes in component selection may be possible in some applications.

- Blend benefits: As a blend component, additional materials leverage the sustainability benefits of ZE and enhance performance above comparative molecules (reference green highlight in Table 1).

Click table to enlarge

TABLE 1: NIST Cycle D Calculations, REFPROP material properties. (Courtesy of Koura)

GWP Isn’t the Whole Story

If the ultimate goal for regulations is decarbonization — targeting net-zero emissions — then minimizing life cycle carbon performance (LCCP) is the key to improving sustainability, not GWP. LCCP represents the comprehensive assessment of emissions throughout a product’s entire life cycle, from its creation (cradle) to its disposal (grave). It accounts for various emissions sources, including:

- Scope 1 (primary emissions): The release of refrigerants into the atmosphere (GWP);

- Scope 2 (secondary emissions): Greenhouse gas emissions from electricity emissions used for equipment power, produced through inefficiency and measured by the coefficient of performance (COP); and

- Scope 3 (embodied emissions): Greenhouse gas emissions from raw materials processing, logistics, installation, and recovery processes.

GWP remains a significant component, because it directly impacts the primary emissions. However, as we focus more on reducing GWP, primary emissions become less of a driver for LCCP, and secondary emissions created through efficiency and COP differences gain importance.

By considering these emissions holistically, LCCP provides a more accurate picture of a product’s environmental impact. By prioritizing emissions beyond GWP, the industry can move closer to decarbonization. GWP still governs carbon dioxide equivalent quota, so implementing lower-GWP refrigerants lets equipment manufacturers use more kilograms of low-GWP refrigerant for the same quota amount of higher-GWP material.

As a result, higher COP (which reduces carbon footprint) is a critical factor for refrigerant selection to pair with capacity.

A2L Transition

We are currently in an intermediate phase, where refrigerant solutions are evolving to meet current and future phasedown regulations. Industry stakeholders, including manufacturers like Orbia Fluor & Energy Materials, are actively exploring and developing alternatives. These alternative materials must balance performance, environmental impact, and safety.

Table 2 shows Orbia Fluor & Energy Material’s view on the current and future material options with existing refrigerant options as they exist today. Refrigerant manufacturers are actively engaging industry leaders to develop new solutions, which would add to this list of options.

| Segment | Pre-AIM |

2024 phasedown choice

(GWP < 750) |

Future phasedown options if GWP < 150 |

| Stationary HVAC | 410A (A1, GWP 1890) |

454B (A2L, GWP 466)

32 (A2L, GWP 675) |

New HFO blend

744 290 |

| Chillers | 134a (A1, GWP 1430) |

513A (A1, GWP 629)

456A (A1, GWP 687) 1234ze (A2L, GWP < 1) |

1234ze (A2L*, GWP 1)

444A (A2L, GWP 93) * US DOT non-flammable |

TABLE 2: Orbia Fluor & Energy Material’s view on current/pre-AIM, 2024 and 2029 refrigerant options for stationary HVAC and chillers. (Courtesy of Koura)

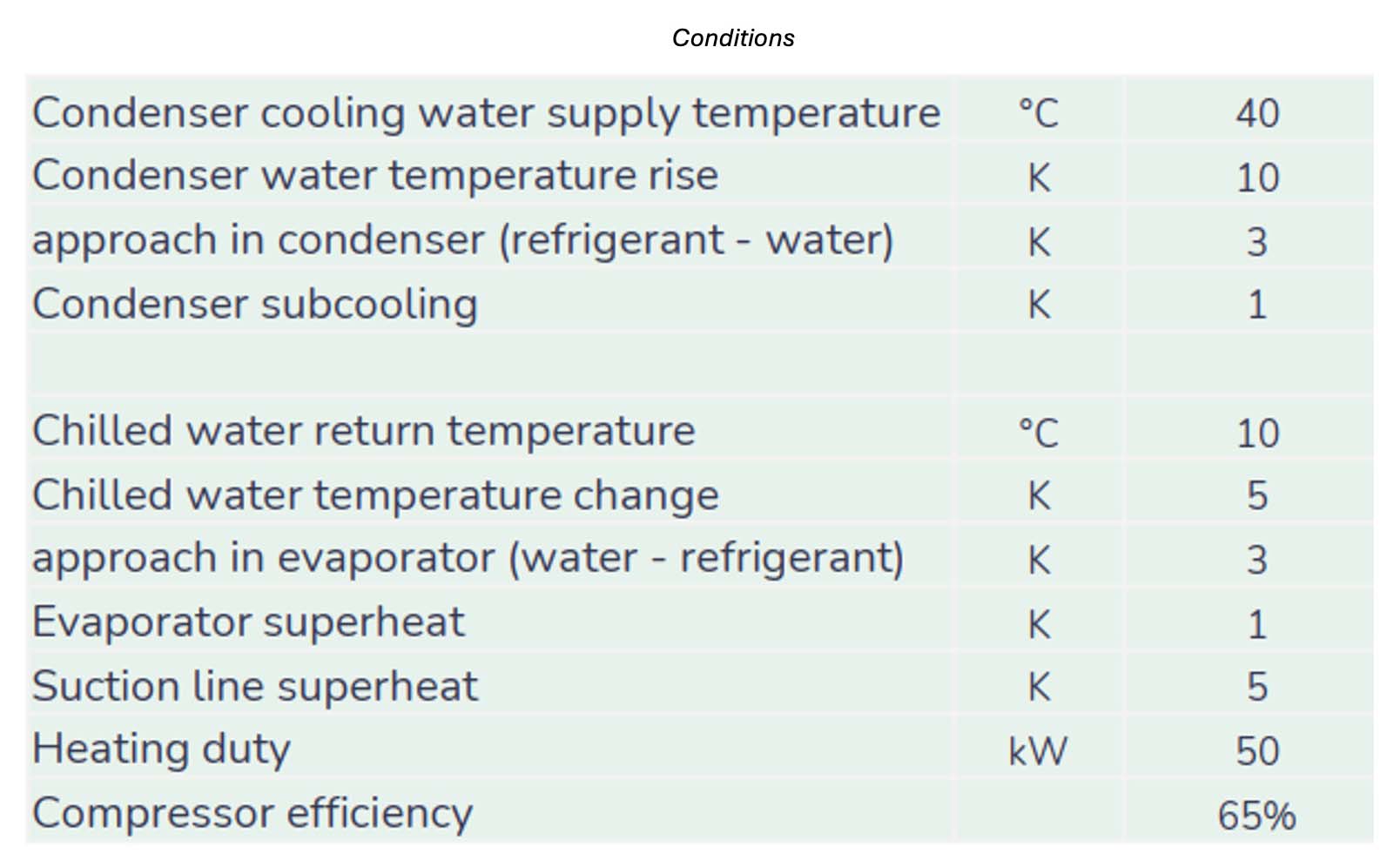

The industry is in a dynamic period of adaptation, innovation, and collaboration as we move toward decarbonization. Orbia Fluor & Energy Materials views R-1234ze(E) as a critical molecule to delivering global sustainability goals through decarbonizing refrigerants. ZE is ideal as a single molecule for chiller or mild-climate applications (see Table 3), or as a blend component with other commercially available refrigerants to customize blends to deliver optimal performance, efficiency, and sustainability.

Click table to enlarge

TABLE 3: Thermodynamic cycle calculation of a data center chiller application using R-1234ze(E). (Courtesy of Koura)

The push for decarbonization has never been more important. With ZE blends, performance no longer has to be a tradeoff for sustainability. Next-generation ZE blends are here, using widely available component materials, while delivering customized performance that is tailored to the application.