Imagine a future where refrigeration systems not only cool your groceries but power entire industries —from nutraceuticals to biodiesel plants — while drastically reducing greenhouse gas emissions. CO2 refrigeration, which has gained significant traction in ice arenas and supermarket coolers, is now emerging as a groundbreaking technology revolutionizing the way we cool and heat across industries worldwide.

As more and more industries take notice, it’s become clear: CO2-based systems are becoming a focal point of innovation.

Why CO2?

As industries and policymakers seek to reduce greenhouse gas emissions and phase out harmful refrigerants, like hydrofluorocarbons (HFCs), CO2 presents an increasingly viable solution.

CO2 refrigeration, also known as R-744, is a naturally occurring gas with several key advantages over traditional refrigerants. The primary benefit is its low global warming potential (GWP). Unlike HFCs, which can have a GWP in the thousands, CO2 has a GWP of 1, making it an environmentally superior alternative. Beyond its sustainability, R-744 is nonflammable and nontoxic in short-term exposures, eliminating the need for extensive safety infrastructure that other refrigerants require.

Supercritical CO2 Technology

As CO2 continues to make headway, supercritical technologies are at the heart of this evolution. Operating at high pressures, supercritical CO2 can exist in both liquid and gas states, making it highly efficient for heat exchange processes.

Pittsburgh, Pennsylvania-based Clean Heat Technologies, a Thar Company, has spent years studying supercritical CO2 and is now utilizing that expertise to push the limits of modern technology. In 2008, the company began experimenting with CO2-infused geothermal projects, and, today, it continues its experimental approach through numerous CO2-based solutions, including heat pumps, high-temperature steam systems, and more.

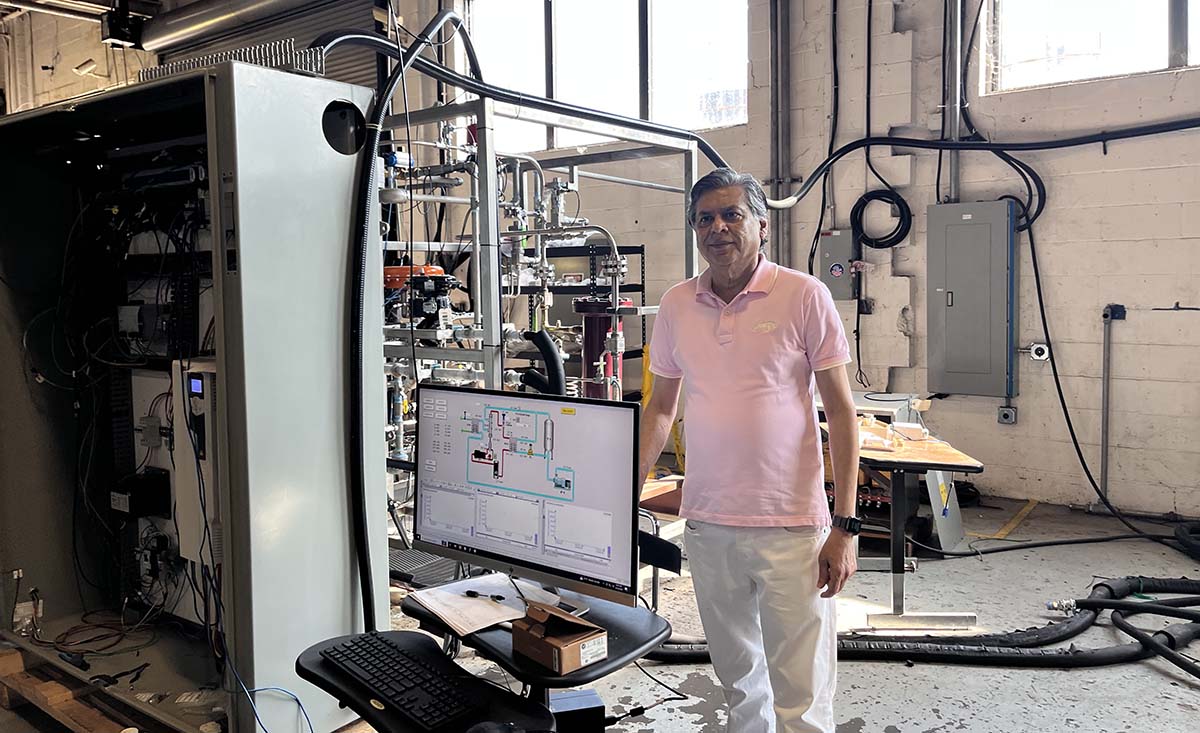

CO2 STEAM DREAM: Lalit Chordia, founder and CEO, Thar Energy LLC and Clean Heat Technologies, stands next to a CO2 steam/hot water system. These systems have many uses, including tall buildings, hospitals, pools, and more. (Courtesy of Clean Heat Technologies)

“Our understanding of the properties of supercritical CO2 allows us to manipulate CO2 from a liquid to supercritical to a gas and then to recycle it,” said Todd Palcic, chief commercial officer, Clean Heat Technologies. “Ultimately, we’re able to produce high-pressure systems with superior heat transfer properties within smaller footprints.”

Palcic said Clean Heat Technologies focuses on reducing clients' operating costs while minimizing their environmental impact when developing solutions, and CO2 refrigeration continues to aid the company on that journey.

“CO2 is nonflammable, which helps keep infrastructure costs down,” said Palcic. “Also, with CO2, we’re not as worried about leaks because it has such a low GWP, and short-term exposure for humans is not an overly dangerous situation.”

The company recently built a CO2 supercritical extraction unit that included an air-source heat pump, which Palcic deemed extremely successful.

“We sold that system to a large nutraceutical company, and it is currently in operation in Arizona,” he said. “The combined heating and cooling solution reduced the existing comfort footprint by approximately two-thirds and energy usage by about 50%.”

Clean Heat Technologies also utilizes supercritical CO2 for extraction purposes, such as cleaning up polymers in waterproofing materials and extracting essential oils contained in fragrances.

“CO2 has a low viscosity, a high diffusivity, and a low surface tension that provides selective extraction, fractionation, and purification,” said Palcic. “This allows it to penetrate micro-and macro-porous materials exceptionally well.”

Upcycling

Beyond supercritical technology, companies like Clean Heat Technologies are finding additional ways to harness the power of CO2 refrigeration systems through upcycling. Upcycling is the process of improving or repurposing existing refrigeration systems that use CO2, making them more efficient or environmentally friendly.

“I consider upcycling a way to make an existing process better – replacing a 20th-century technology with a 21st-century technology,” said Palcic. “For example, entrepreneurs aren’t as focused on improving combustion engines anymore – they’re focused on electric vehicles or hydrogen systems, electric planes, flying cars, etc. The same can be said about hydrocarbons or HFCs — we’re not looking to go backward; rather, we’re only interested in moving forward.”

The Future Is Near

While upcycling is one way to improve today’s CO2 refrigeration systems, the future holds even more promise. Palcic predicts CO2 will expand far beyond its current applications, revolutionizing industries ranging from biodiesel processing to data centers in the coming years.

“CO2 refrigeration will be huge in the processing of vegetable oil, biodiesel, and acetyl extraction,” he said. “There are numerous $200-$400 million plants being built, and I believe many of them will utilize supercritical CO2. Anywhere there’s a press involved, or cooling in the extraction process, you can expect CO2 to be on-site.”

He also believes the dual capabilities of CO2 heat pumps will have a major role in various industries.

“The hybrid heat pump approach offers advantages for nearly every facility that has a need for both cooling and heating,” he said. “From grocery stores to pharmaceutical facilities, hospitals, and more, the demand is there. Laboratories and manufacturing are great examples of industries that may benefit from packaged cooling, heating, and hot water solutions. Other industries, like data centers, may benefit from supercritical CO2 as well.”

As CO2 refrigeration continues to make inroads in the U.S., Palcic encourages contractors to dive in as soon as possible, as those who have yet to adopt it may find themselves playing catch-up sooner than later.

“Contractors may have concerns about pressure and leakage; however, if they’re skilled in the refrigeration cycle, with a little training, they can handle CO2 — it’s not that much different,” said Palcic. “Supercritical CO2 represents a significant leap toward a more sustainable future. Those who invest in CO2 expertise now will be the leaders in tomorrow’s refrigerant industry, and Clean Heat Technologies is here to help.”