The International Air-Conditioning, Heating, Refrigerating Exposition (AHR Expo) recently announced the winners of the 2025 AHR Expo Innovation Awards, and they include 10 of the most innovative products and technologies in the market. A panel of distinguished ASHRAE members serving as third-party judges selected the winners based on criteria that included overall innovative design, creativity of the product or service offered, product or technology real-world application, and overall potential market impact.

“To be recognized as an award winner is a true honor within our industry,” said Mark Stevens, show manager of AHR Expo. “We are thrilled to highlight the dedication of manufacturers and team members as they work to create real solutions. The Innovation Awards aim to highlight these companies, professionals, and their innovation trajectory and to celebrate those that are pushing the bar.”

In addition to category winners, one overall 2025 Product of the Year winner will be announced and awarded at the AHR Expo, which takes place February 10-12, 2025, in Orlando, Florida.

All product images have been provided by the manufacturers.

Building Automation

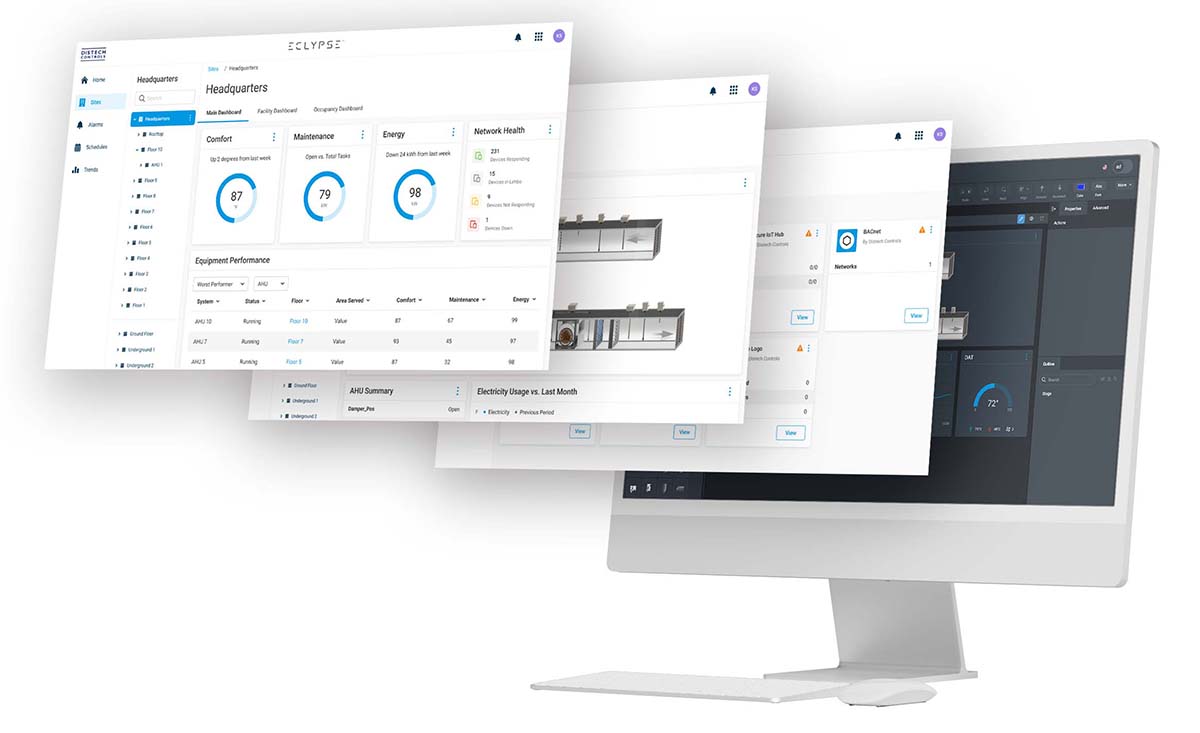

Winner: Distech Controls

Innovation: Eclypse Facilities

AHR Booth: 781

Eclypse Facilities is a software solution embedded directly within Distech Controls’ Eclypse devices, which provides management and control for a variety of equipment types within buildings. It provides a secure, embedded platform that ensures seamless control of equipment, plant rooms, and spaces along with its associated tools.

“With this new software solution, we are addressing a number of challenges the industry is facing, including energy volatility, labor shortages, enhanced user experiences, and cybersecurity,” said Charles Pelletier, vice president of product management at Distech Controls. “By having the right infrastructure and the right technology, we can deliver buildings that continuously evolve and improve over time. We can connect the building with services through API to create better experiences in the places we work, live, and learn.”

According to the company, Eclypse Facilities streamlines the design, deployment, operation, and maintenance of sustainable and connected buildings with unparalleled efficiency. Contractors, facility managers, and building owners can all benefit as the software solution delivers feature-rich commercial buildings that are efficient, autonomous, and human-centric.

“It also allows stakeholders to develop flexible buildings, which fully accommodate the needs of the occupants,” said Pelletier. “System integrators are able to install the system faster and easier, saving time and cost for their business. With more data and analytics available, property owners and facility managers can also minimize costs with efficient building management to optimize operating costs.”

Eclypse Facilities is available as part of a new suite of BMS solutions through Distech Controls, which also includes Atrius Facilities and EC-Net Facilities. Atrius Facilities is a cloud-based BMS software solution designed to enhance building operations and reduce energy usage. The EC-Net Facilities software solution leverages the Niagara framework both at the building controller and server level which specializes in advanced management and visualization of building devices across small to large portfolios.

“Eclypse Facilities will transform the built environment and make buildings more energy efficient, more autonomous, and reduce the complexity of the BMS, as well as create better experiences in spaces,” said Pelletier.

Cooling

Winner: Climate Control Group

Innovation: EnviroKit Comprehensive Retrofit Solution

AHR Booth: 3927

The EnviroKit Comprehensive Retrofit Solution was designed for aging vertical stack fan coil units in applications including hospitality, multifamily housing, and senior living. It addresses a critical need in the marketplace: a quick, simple, and budget-friendly solution that restores fan coil unit performance without the need for extensive demolition or major renovations, keeping rooms operational and minimizing revenue disruptions.

Disruptions in room availability due to HVAC repairs can be costly, as room outages affect revenue and guest experiences. This challenge is particularly prevalent in properties with aging hydronic systems, where components have aged to the point of causing underperformance, leading to both discomfort and higher maintenance costs.

“Before EnviroKit, the typical solution for these issues would have been either a full fan coil unit replacement or extensive field replacements for individual parts — a process that could be time-consuming and complex,” said Shane Lantz, aftermarket sales manager at Climate Control Group. “EnviroKit was developed by International Environmental Corporation (a division of the Climate Control Group) to offer a streamlined, efficient alternative that minimizes room downtime and avoids major disruptions while restoring HVAC systems to optimal performance.”

The EnviroKit is a customizable solution that can be scaled to meet the specific needs of any project. The following comprehensive solution offers a complete set of components designed to simplify the retrofitting process:

- High-efficiency EC motors and blower housings for optimized energy savings and performance;

- Options that include control kits, double-sloped stainless-steel drain pans, and valve packages, encased in durable 20-gauge galvanized steel for easy reliable installation;

- Nearly plug-and-play compatibility, as it works seamlessly with existing thermostats; and

- Flexible configurations with high-efficiency copper tube-aluminum fin coils and options for cooling (3 or 4 row) or hydronic heating (1 or 2 row).

“EnviroKit was built with contractors and installation teams in mind,” said Lantz. “The comprehensive kit is exceptionally easy to work with — technicians simply remove the aged parts, insert the new assembly, and make the necessary connections. The EnviroKIT streamlines the retrofit process, allowing contractors to quickly complete installations without complex assembly or demolition, saving time and reducing labor costs.”

Heating

Winner: Aerco, a Watts Brand

Innovation: CFR stainless steel condensing boiler

AHR Booth: 743

The CFR stainless steel condensing boiler was developed to provide customers with an advanced, compact boiler that allows them to upgrade their existing heating system to high efficiency while safely and cost-effectively reusing their existing Category I venting. The CFR provides up to 87.6% thermal efficiency and is available in 1,500 MBH and 3,000 MBH models.

“The innovative design of the CFR enables condensation to occur within the heat exchanger while maintaining dry flue gas via its unique StackGuard sensor, thereby allowing the boiler to use existing Category I venting and eliminating costly upgrades,” said Christian Zapata, product manager at AERCO. “Its compact durable build and 87.6% efficiency make it an ideal retrofit solution for facilities aiming to boost energy efficiency and cut emissions without extensive infrastructure changes. In this way, CFR offers a unique path to cost-effectively enhance energy savings and meet emissions goals, making it ideal for facilities that would otherwise be faced with cost-prohibitive venting upgrades.”

Features of the CFR boiler include the advanced Edge controller, which optimizes system efficiency and operation and easily integrates the CFR with building automation systems. A 439 stainless steel heat exchanger offers condensation resilience, while the CFR’s fire-tube design allows varied piping configurations. The CFR is also compatible with Aerco’s SmartPlate EV indirect water heater for high-efficiency combination plants.

“CFR’s compact design, combined with its ability to fit through standard doorways and zero-side clearance, makes the units not only easy to install and service but also helps reduce costs,” said Zapata. “CFR provides vertical discharge venting and room/air ducted combustion capabilities, and the fire-tube design allows for various piping configurations, including variable-primary. Secondary and bypass pumps are not required, which further lowers installation costs. The CFR also provides access for service from multiple directions, making maintenance straightforward. The smart Edge controller optimizes performance and simplifies boiler sequencing, while helping technicians with setup and ongoing management.”

Indoor Air Quality

Winner: Senva Inc.

Innovation: TotalSense Indoor Environmental and Air Quality Sensor

AHR Booth: 581

The TotalSense Indoor Environmental and Air Quality Sensor integrates 10 sensing technologies, including particulate matter (PM), total volatile organic compounds (TVOC), carbon dioxide (CO2), carbon monoxide (CO), ozone (O3), passive infrared (PIR) motion detection, relative humidity (RH), ambient light, temperature, and barometric pressure. The sensor provides real-time data to optimize air purification, ventilation, and overall indoor environmental quality and also helps validate the effectiveness of air filtration and purification methods.

“The catalyst for creating the TotalSense was the increased focus on IAQ during the COVID-19 pandemic,” said Diana Laboy-Rush, senior product manager at Senva Inc. “As vaccines rolled out and building occupancy started to recover, there was a growing demand for improved ventilation strategies to ensure safety and peace of mind. The TotalSense was developed to meet this need, offering a comprehensive solution that monitors various aspects of indoor air quality.”

TotalSense is primarily designed for commercial applications and is suitable for both new construction and retrofit projects. Ideal applications include office buildings, medical facilities, and fitness centers or gyms. Educational facilities are also a good fit, said Laboy-Rush, as many older buildings have boilers or outdated HVAC systems, which can lead to potential CO and ozone concerns. By monitoring these gases, along with CO2, TotalSense ensures ventilation strategies are effectively safeguarding students and staff, she said.

TotalSense’s flexibility extends to indoor, outdoor, and duct applications and seamless integration with building automation systems via BACnet, Modbus, and analog outputs. Its programmable relay allows it to act as a local controller, managing nearby devices to enhance connected building operations.

“For HVACR contractors and technicians, TotalSense offers groundbreaking benefits, as it makes installation, servicing, and integration remarkably efficient,” said Laboy-Rush. “Designed with a streamlined setup, TotalSense leverages the SenvaSync NFC app, which allows rapid customization and consistent programming across multiple devices with ease. The sensor’s built-to-order configurations mean it arrives job-ready, tailored to specific project needs, and with next-day shipping on most orders, it minimizes project delays, keeping schedules on track.”

Maintenance is exceptionally user-friendly, as all sensors are factory-calibrated, including CO and O3, ensuring accuracy right out of the box, said Laboy-Rush.

“For HVACR professionals, TotalSense isn’t just a sensor — it’s a high-performance tool that enhances efficiency, reliability, and effectiveness in air quality solutions.”

Plumbing

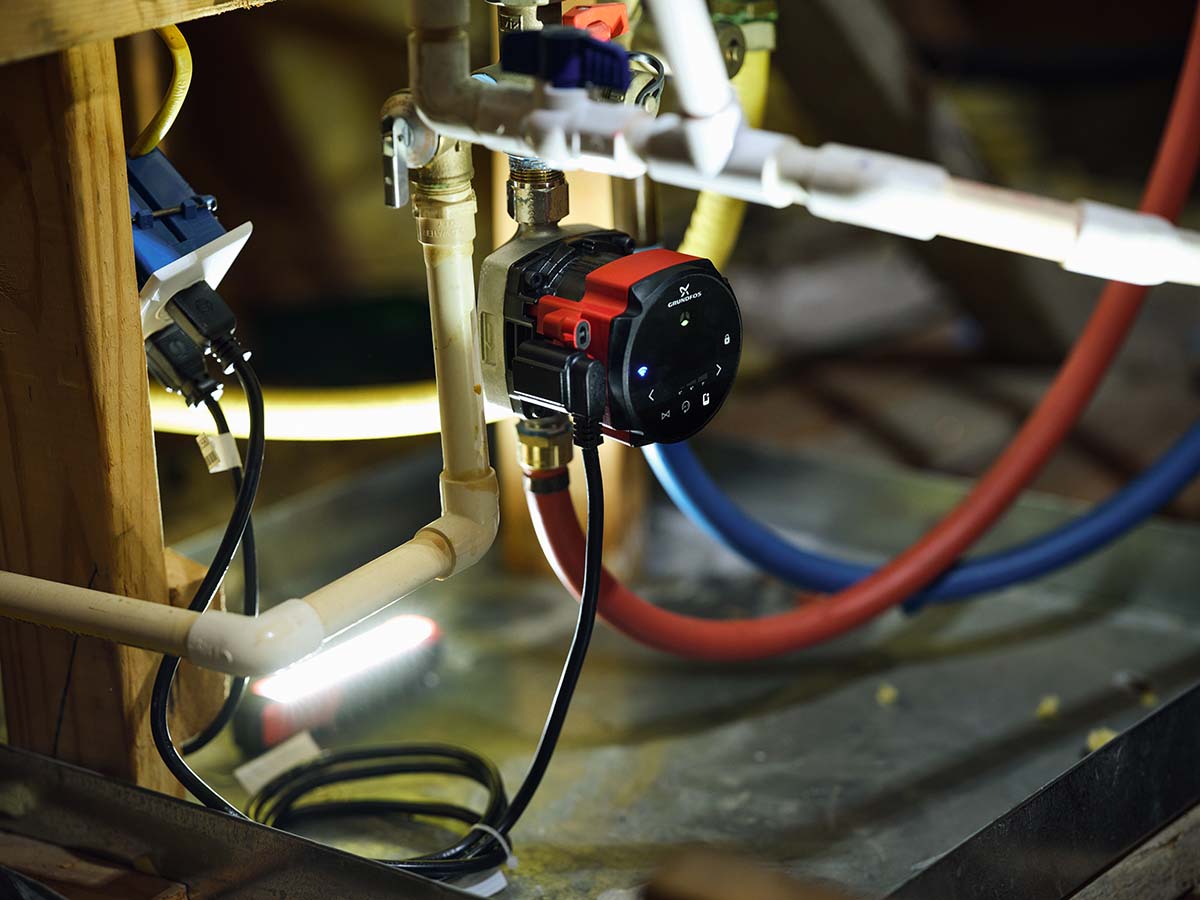

Winner: Grundfos

Innovation: Alpha HWR circulator pump

AHR Booth: 1808

The Alpha HWR is a high-efficiency, digitally connected circulator designed for hot water systems with a dedicated return line. It is a three-in-one solution that includes the high-efficiency pump, timer, and temperature sensor. It also includes intelligent features to ensure the pump only runs when hot water is needed, minimizing consumption and reducing energy bills when replacing a non-ECM pump.

“The Alpha HWR sets a new standard for energy efficiency, encouraging manufacturers to prioritize sustainable, cost-saving solutions,” said David McMillian, vice president of sales for DBS Trade. “By addressing common issues of water waste and pinhole risk due to extra flow, the pump establishes an outline for industry advancements. As part of a line of innovative water pumps that cater to homeowners' evolving needs and values, the Alpha HWR is redefining efficiency, comfort, and eco-consciousness standards.”

The new Alpha HWR circulator pump combines advanced features to enhance installation, troubleshooting, and system optimization for installers. Its guided setup offers mode and setting recommendations to ensure optimal system performance, while built-in firmware updates streamline troubleshooting for a faster and more efficient resolution of pump or system concerns. The pump’s reliable software updates ensure it remains up to date with the latest developments, while its intelligent air venting capabilities simplify commissioning. The Alpha HWR also connects to the Grundfos Go app, which can control pumps and monitor duty points, power consumption, settings, and temperature.

The Alpha HWR can save up to 12,000 gallons of water annually in the average U.S. home by reducing the amount wasted while waiting for hot water to reach the tap, said McMillian. By providing instant hot water, he added, the system eliminates the need to let the water run until it reaches the desired temperature, conserving resources, and lowering utility bills by up to 88% compared to traditional recirculation pumps.

“The Alpha HWR and its partner, the ALPHA CS — for homes without a dedicated return line — were designed to increase comfort and upgrade everyday moments with access to instant hot water precisely when needed,” said McMillian. “The Grundfos Alpha HWR is an excellent choice for homeowners seeking to save time, improve water efficiency, save on utility costs (water, wastewater, and energy), and enjoy a more comfortable living environment with instant hot water access.”

Refrigeration

Winner: Danfoss

Innovation: Bock HGX56 CO2 T compressor

AHR Booth: 1301

The Bock HGX56 CO2 T is a transcritical, semi-hermetic, CO2 (R-744) compressor that is ideal for industrial refrigeration, cold storage, ice sports facilities, and heat pumps. The expansion to 6-cylinder capacity allows for a wider spread and faster uptake of large CO2 heat pumps and industrial refrigeration systems, along with lower system complexity and investment costs. It also provides an attractive alternative to compressors using ammonia or HFC or HFO refrigerants.

“The Bock HGX56 CO2 T extends the range of CO2 products available along with the ability to produce up to 90°C/194°F water temperature with higher efficiency, which surpasses products currently available,” said Howell Feig, director of North America business development for Bock at Danfoss. “In general, this range offers more flexibility to cover a wider range of applications, including low-temperature to high-temperature heat pumps with reliable, flexible, partial, and full load.”

The new 6-cylinder design ensures greater capacities while reducing the number of compressors. With its high efficiency and reliability, this CO2 compressor enables larger refrigeration and heat pump applications with a smaller footprint and strong energy-efficient performance. Additional benefits include low energy and operating costs (ASERCOM certified), outstanding running performance with low noise and vibration, and minimal oil carryover, with capacity up to 135 KW for cooling and 360 kW for heating.

“Supporting customers in their transition to low-GWP refrigerants is a key priority for Danfoss,” said Feig. “The company’s dedication to environmental responsibility drives the continuous development of efficient and reliable CO2 compressors that guarantee peak plant efficiency while minimizing investment, energy, and operating costs.”

Software

Winner: Radiant Professionals Alliance

Innovation: Building Efficiency System Tool (BEST)

AHR Booth: 2175

The Building Efficiency System Tool (BEST) was developed to empower building owners and their design teams to evaluate different heating and cooling options early in the planning process, before starting engineered designs. Designed for commercial applications, BEST was built on real-world data from the Hydronics Industry Alliance committees’ working group, industry partners, and insights from contractors. This collective data offers users a realistic starting point for comparing system costs and performance.

“Prior to the availability of BEST, many owners didn’t perform early-stage modeling due to the high costs, time constraints, or limited knowledge of the available alternatives,” said John A. Mullen, technical liaison to IAPMO’s Radiant Professionals Alliance. “BEST addresses these challenges by offering a user-friendly, free tool that enables side-by-side comparisons of heating and cooling system options. This approach brings data-driven insights to the forefront and provides building owners with actionable information based on reliable, constantly updated data, allowing owners to adopt options confidently and make informed decisions that align with today’s sustainability demands.”

BEST features multiple system outputs based on real case studies, customizable by location, weather data, utility costs (sourced from eia.gov), building size, and function. With over 100 building-specific inputs and access to over 1,000 sets of bin weather data for Canada, the U.S., and Mexico, BEST tailors results to fit each unique project, wherever it’s located.

“Rather than calculating load data from scratch, the software allows users to input and adjust load specifics and installation costs along with hundreds of other variables,” said Mullen. “Results are presented across nine detailed reports, giving users a comprehensive view of system performance, costs, and potential savings to guide their decisions.”

BEST provides near-instantaneous results and is designed for easy, offline use by contractors and technicians who need fast, reliable data. The software runs directly on the user's computer, avoiding cloud-based data capture, which can be a key requirement for government contractors or PEs who want job-specific data to remain confidential and privacy protected.

“Version 6.2 of BEST is available now, but stay tuned for V 7.0 to debut in early 2025, with a host of new updates and enhancements,” said Mullen.

Sustainable Solutions

Winner: LG Electronics U.S.A. Inc.

Innovation: Residential Cold Climate Heat Pump

AHR Booth: 6643

LG’s Residential Cold Climate Heat Pump (CCHP) is designed for cold regions and has the capability to operate at temperatures as low as -31°F (-35°C). It retains full heating capacity at -13°F (-25°C) and continues to function at 70% capacity even under the extreme conditions of -31°F (-35°C). Traditional heat pumps often exhibit a marked decline in performance when faced with temperatures below 0°F (-17.8°C), reducing their reliability and efficiency in cold climate regions.

“Addressing the inefficiencies of heat pumps in extreme low-temperature regions presents a significant challenge, primarily due to the decrease in refrigerant circulation induced by the cold,” said Derryl Wright, P.E., manager for LG platform management at LG Electronics U.S.A. Inc. “Recognizing this issue, LG has prioritized the development and validation of products specifically designed for such harsh conditions. These solutions aim to augment indoor comfort and deliver heat without an exclusive dependence on fossil fuel energy sources.”

LG’s CCHP features a unique refrigerant cycle that prevents frost accumulation on the outdoor heat exchanger, ensuring its effective heating performance down to -31°F (-35°C). Additionally, it uses a high-capacity, high-efficiency twin rotary inverter compressor with low-GWP R-32 refrigerant. The system’s efficiency output boasts an HSPF2 rating of 11.2 Btu/Wh at 13 kBtuh.

According to Wright, the CCHP enables contractors and installers in very cold climates to offer a broader range of heat pump solutions that provide year-round comfort and improved energy efficiency. By reducing energy consumption, the heat pump further contributes to climate change mitigation, he said, which can be a significant selling point for contractors aiming to offer more environmentally conscious solutions.

“The heat pump can also contribute to the reduction of fossil fuel usage in cold regions by eliminating or significantly decreasing the need for additional back-up heating,” said Wright. “By lessening reliance on fossil fuel-based heating systems, the LG Residential Cold Climate Heat Pump can play a crucial role in addressing environmental challenges and contribute to a greener future.”

Tools & Instruments

Winner: PassiveLogic

Innovation: Sense Nano wireless building sensor

AHR Booth: 1191, 1391

The Sense Nano is a wireless building sensor powered by ambient light, which delivers professional-grade monitoring in a package that is smaller than an Oreo cookie. The combination of wireless operation, rapid deployment, and integration with PassiveLogic's autonomous building platform enables a level of building optimization previously thought impossible at this price point.

The Sense Nano was developed in response to a problem PassiveLogic experienced while creating its autonomous building platform. According to CEO and founder Troy Harvey, the company realized that existing sensors were inadequate for their needs.

“They were expensive to install, difficult to integrate, and couldn't provide the comprehensive data needed for true building optimization,” he said. “We needed sensors that could be deployed anywhere, gather multiple environmental parameters, and seamlessly integrate with our system. Rather than compromise, we created the Sense Nano — a revolutionary sensor that harvests energy from ambient indoor light, eliminating expensive wiring while delivering professional-grade monitoring. The result? Projects that once took weeks now complete in hours, enabling building owners to achieve the sensor coverage needed for autonomous building control at a fraction of traditional costs.”

The Sense Nano sensor measures seven environmental parameters — air temperature, radiant temperature, humidity, atmospheric pressure, light intensity, occupancy, and air quality (wired version). Powered by ambient light with a one-year battery backup, it features a compact design (1.77-inch diameter and 0.45-inch height) and tool-free installation. The sensor integrates seamlessly with PassiveLogic Hive controllers and supports automatic commissioning through the Quantum Lens mobile app for real-time monitoring and control.

“For contractors and technicians, the Sense Nano dramatically simplifies installation and commissioning,” said Harvey. “No electrician is needed for wireless installations, and setup takes under a minute per sensor using our mobile app — simply stick it to the wall and scan with your phone. The device automatically joins the building's mesh network and begins streaming data to the Hive controller. This simplicity enables contractors to complete more projects faster while delivering superior building control capabilities to their customers.”

The Sense Nano can be used in virtually any application, from retrofitting historic buildings where running new wires isn't feasible, to new commercial construction seeking cost-effective solutions. Harvey said this versatility makes it ideal for offices, schools, multifamily housing, and commercial buildings of any size.

Ventilation

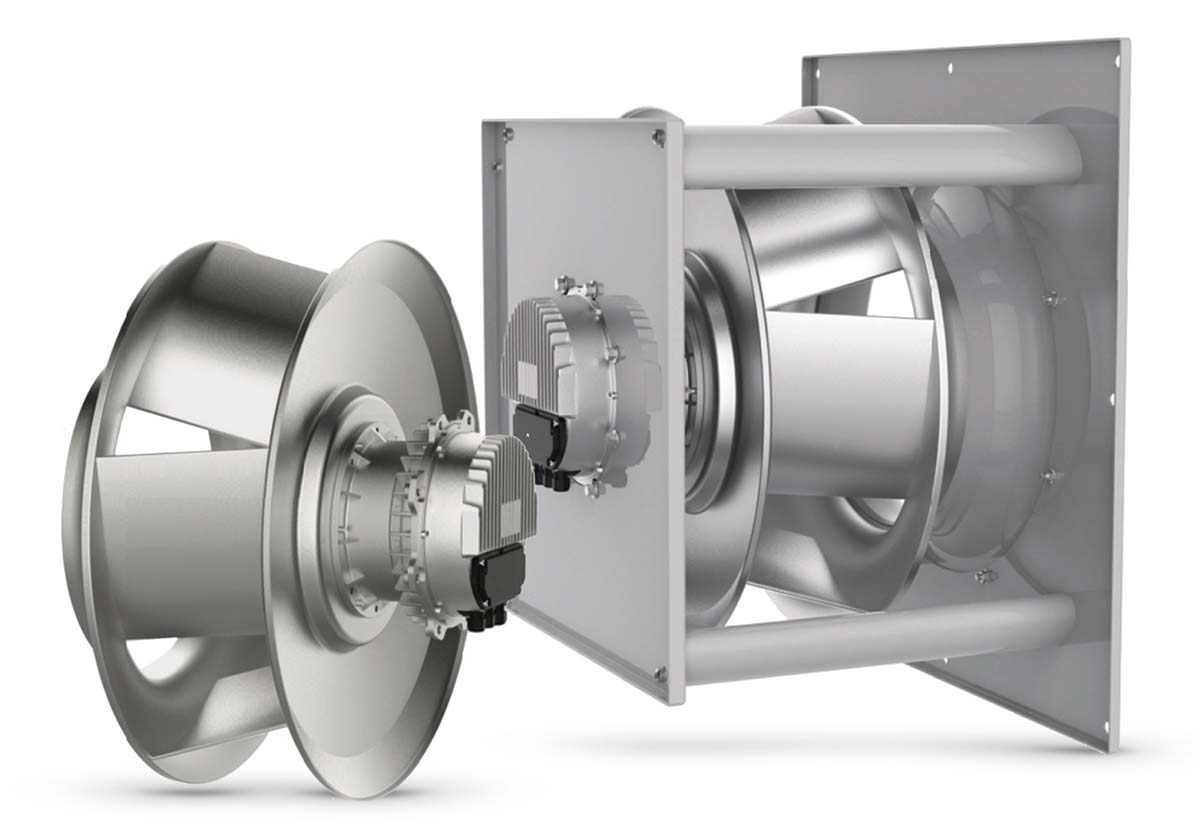

Winner: Rosenberg USA Inc.

Innovation: I-Series Backward Curved Fans

AHR Booth: 5751

The new I-Series impeller can increase efficiencies up to 11%, while reducing noise levels by more than half compared to older impellers. This makes it an ideal solution for many types of commercial environments, including data centers, air filtration in clean rooms and hospitals, and equipment cooling in VFD and UPS applications. Rosenberg has developed 23 models of I-Series fans, ranging from 355MM to 630MM, available as modules or motorized impellers.

“Innovation is a major part of our mission at Rosenberg,” said Zach Hensel, EC product manager at Rosenberg USA Inc. “Air movement innovation is very important to our company, to our industry, and to the world. Rosenberg is constantly working on improvements in air movement technology to help drive increased efficiency in HVAC, refrigeration, data center cooling — making life better, while reducing environmental impact. The new I-Series impeller is the result of our continuing advancement process.”

Rosenberg’s unique “I-impeller” design is an airflow-orientated, high-performance impeller that provides a constant high degree of efficiency, even under partial load. The impeller is made of aluminum (AlMg3) with five backward-curved, profiled blades and an efficiency-optimized circumferential diffusor. The unique blade profile is sound optimized, and the aluminum impeller construction makes the fans easier to recycle when they reach end of life.

The reduced noise level is just one of the reasons why HVAC contractors should consider choosing the I-Series line fans, especially in air handling units, where they can cut noise by up to 50% compared to older fans, said Hensel.

“In addition, I-Series fans provide up to 12% more airflow, depending on the operating point,” he said. “They are also compact in design and 100% speed-controllable. Data center operators and equipment manufacturers should consider the I-Series fans, because they reach efficiency levels of up to 71% — 3% points better than the previously available fans — significantly reducing energy cost. They are also driven by our advanced-design Gen3 and Gen3+ EC motors operating at up to 7.2 kW of power input, which results in 20% to 30% more cooling power compared to our previous motor generations. More sophisticated electronics are built-in for communication, control, and greater reliability.”