As a kid, Brett Wetzel thought he had it all figured out. He left his house at 16 years old with a chip on his shoulder, ready to take on the world. Unfortunately, he quickly realized he’d bitten off more than he could chew. He bounced around, seeking firm direction, often ending up back where he started. For a couple of years, he was essentially homeless, living in his car, doing what he could to keep his head above water.

Always good with his hands, he dove into the books, earning an electrical engineering degree, but, unfortunately, once he put his skills to the test, he discovered he hated engineering.

ALL SYSTEMS GO: Wetzel gives a thumb’s up after successfully troubleshooting a CO2 refrigeration system. (Courtesy of Brett Wetzel)

Not willing to completely turn his back on the trades, Wetzel visited Home Depot. There, he maxed out the $2,000 limit on his credit card, filling his truck with as many tools as he could, and began answering help-wanted ads.

While he was surprised at how quickly he landed an HVAC job, he discovered his first job wasn’t quite the dream position he hoped it was.

“I was thrilled to have a job; however, within three weeks of working for this guy, he began tearing me down on a daily basis, telling me, ‘You’ll never amount to anything — you’re worthless.’ He told me I was the biggest piece of crap he’d ever met,” said Wetzel. “I left shortly thereafter.”

Yet again, after pouring everything he had — mentally and financially — into a career he knew he was destined for, Wetzel found himself back at square one.

However, Wetzel wasn’t going down without a fight. The HVAC “boss’s” venomous words fueled his fire. From that point forward, he dedicated himself to the refrigeration industry and, more importantly, doing everything he could to ensure those he worked with and around were treated fairly.

“That interaction has stuck with me my entire life,” said Wetzel. “I’ve made it my goal to never treat anyone like that and to ensure that no one in my presence is treated like that. Ever.”

The Refrigeration Guru

Wetzel eventually landed on his feet within the industry, working as a commercial and industrial refrigeration technician in Pennsylvania and Connecticut. Over the next six years, he gained invaluable experience grinding in the trenches. Eventually, he outgrew the position and began seeking a change of scenery.

In November 2015, he was hired by CoolSys as a level-six technician. Very quickly thereafter, he rose to a level-seven tech before being named a service supervisor in Dallas. In addition to directing a team of 13 techs, he became the lead trainer for the company’s in-house training program. As a result, Wetzel began dedicating more of his time into the classroom, and while that solved one problem — the lack of early-on education — it created another.

“Management was complaining about stuff not getting done — that things were always broken,” said Wetzel. “The demand was growing, and, honestly, I was kind of getting bored of teaching the same stuff to the same people, so, I proposed that I spend less time in the classroom and more time on-site, helping to solve that problem. And, they agreed, so I hit the road, helping to put out fires and train local techs on how to keep these problems from reoccurring.”

But, unfortunately, there’s only one Brett Wetzel, and no matter how hard he tried, he couldn’t be available to fix every problem at every location across the region.

“I’d reached a point when it was time for me to go,” said Wetzel. “I let management know, ‘Hey, it’s not you, it’s me. I’m just not having fun anymore.’ So, I put my two-weeks’ notice in and prepared to move on to something else.”

Once the company’s vice president of operations caught wind of Wetzel’s resignation, he called. Then, another high-ranking official called, and they devised a plan to deploy Wetzel nationally as a trainer and on-site leader. He agreed and stayed on with the company.

“I wrote an entirely new curriculum, focusing on an introduction to CO2, CO2 transcritical refrigeration, etc.,” he said. “In our first year, we trained 270 people in person and online. We introduced a lot of technicians to CO2, which was a great thing — we were making a difference.”

Teaching CO2

While on the road, Wetzel was surprised to learn that many techs were frightened by R-744 and its high pressures — a fear that he insists is largely unwarranted.

“Yes, CO2 operates at a higher pressure, and that seems to really freak people out,” he said. “But once you understand how to control that pressure, it’s not all that difficult.

“Once CO2 reaches a certain point on the PT chart, there’s no pressure temperature correlation anymore,” continued Wetzel. “We don’t know if it’s a liquid or a gas. You must open the system and take scientific measurements to find out. That being said, once CO2 hits 87°F saturated, it’s a plasma-to-a-vapor. It's a ‘we don't know what it is’ — basically the Schrödinger's cat of refrigeration.”

CO2 refrigeration requires careful attention to detail, not only in the design but in the numbers behind it.

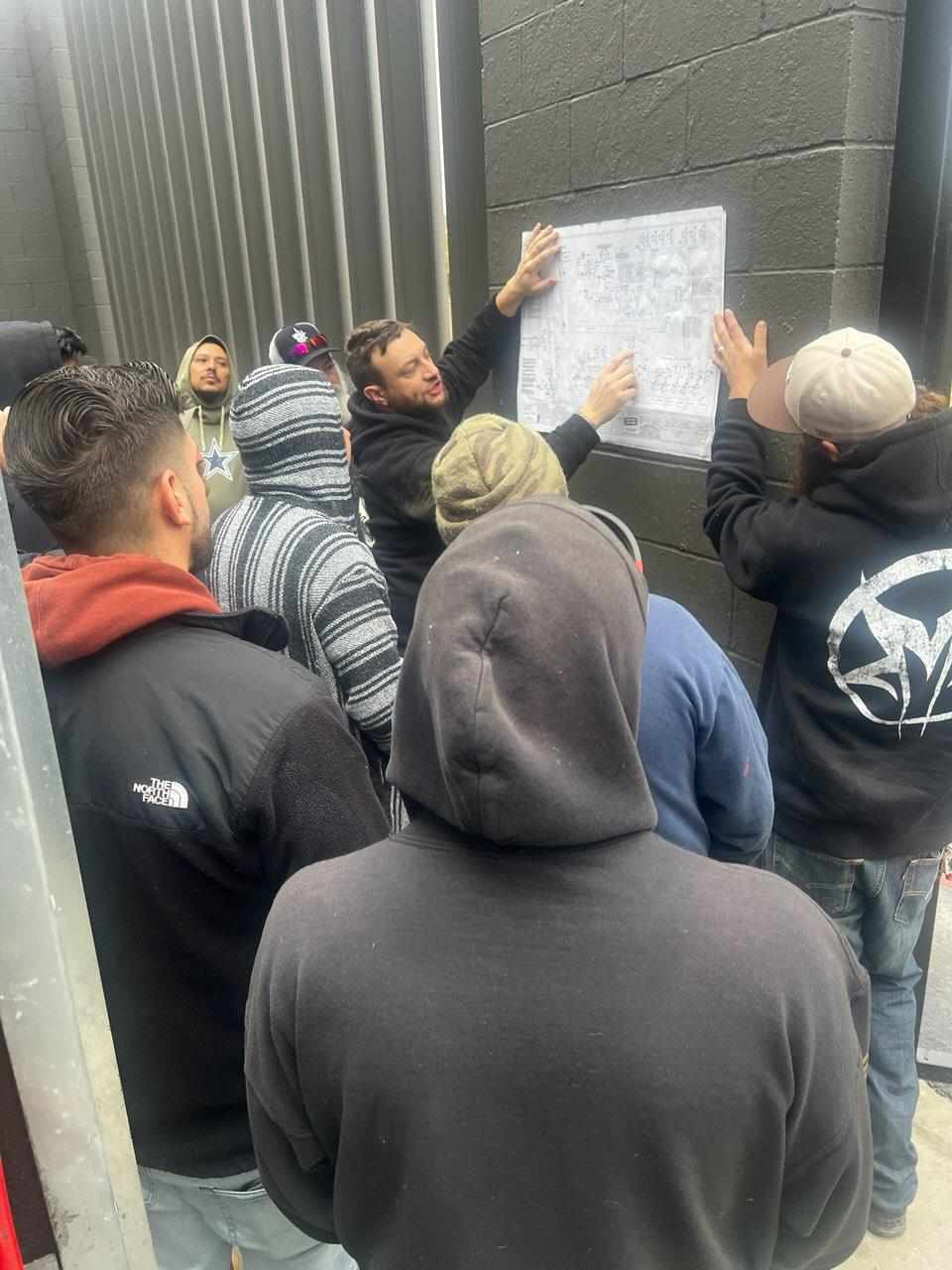

HANDS-ON INSTRUCTION: Wetzel demonstrates the proper sequence for a CO2 system before a group of learning HVACR technicians. (Courtesy of Brett Wetzel)

“The math with the flash tank and high-pressure valve [HPV], going into the flash tank from the gas cooler, that concept really throws cats off,” Wetzel said. “And it threw me off for a very long time, because if you do the math, it doesn't make any sense. Theoretically, if you have 75° saturated condensing temperature, that HPV is trying to control 5° of subcooling. But then it opens up even further and goes all the way down in the flash tank to 38° saturated. Theoretically, if the liquid is warmer than 38°, it's supposed to be a vapor, right? Well, in this instance that doesn't hold fully true.

“Due to the enthalpy during subcritical operation, you'll probably get about 70% liquid production, and 30% vapor of that is waste — that's why they call an HPV an HPV, because it’s designed to reduce the pressure,” continued Wetzel. “It’s trying to control subcooling when it's subcritical. But that's what we're doing here. And, so, with that math, you’re like, wait a minute — you're going from 75° saturated to 38°. Well, that means you have vapor, right? Well, no, not totally.

“Once we go to that transcritical function, we change the control strategy to now just controlling the pressure based off of the gas cooler outlet sensor, which leads to the liquid production does go down to as low as 50% liquid and 50% vapor,” Wetzel continued. “That's why we have more multiple-compressor configurations on the medium-temp side than we do on the low-temp side, because once it hits transcritical, that extra mass of vapor has to be compressed by something. So, until we install something to pull that flash gas down to the 38° saturated, like parallel compressors, the medium temp compressors must handle the flash gas, right?”

CO2 refrigeration certainly requires some focused education. However, for techs with refrigeration experience, Wetzel is confident they can grasp the most basic concepts in just a few days.

“Refrigeration guys with HFO [hydrofluoroolefin] or HFC [hydrofluorocarbon] experience should be able to pick it up fairly quickly,” he said. “Once you start to incorporate the controls, that may take a little bit more time. But, if you focus on the sequence of operations, take the time to understand the manual, and recognize the safety risks, it’s not too much different than a traditional system.”

Among the Best

When not teaching in a classroom, Wetzel can be found sharing his 20-plus years of HVAC knowledge online through his Advanced Refrigeration Podcast, in which he’s recorded more than 350 episodes focused on HVAC refrigeration.

His ability to connect with techs has elevated his reputation as a refrigeration trainer. He was named the HVAC Tactical Mentor of the Year in 2024 and a Top 25 Most Influential Instructor/Trainer in 2025 by HVAC Excellence. He recently presented CO2 courses at North American Sustainable Refrigeration Council (NASRAC) events, will be presenting at the 2025 AHR Expo, and announced his intention to lead HVACRedu.net’s latest CO2 training curriculum, “446 – Introduction to CO2 Refrigeration Systems”.

His unflinching dedication to the trade has undoubtedly earned a spot on the modern-day Mount Rushmore of CO2 refrigeration instructors.

INDUSTRY INFLUENCER: Wetzel continues to pour his heart and soul into the industry, delivering classroom lectures, recording countless podcast episodes, and leaving his fingerprints on as many compressors as possible. (Courtesy of Brett Wetzel)

“I aim to teach in a fashion that connects with everyone, which is important, because everyone learns differently; however, when it comes to diagnosing issues, it’s important to start inside the mechanical room.” he said. “Some teachers are great at what they do, but, for whatever reason, they fail to connect with certain students. I’m focused on teaching students what they really need to know in a way that’s easily digestible.”

In late 2024, Wetzel embarked upon a new endeavor, joining Future Green Now as director of strategic technical services and solutions. While his title may have changed, he remains committed to driving sustainable innovations through on-site commissioning, consulting, and developing customized training programs for the HVACR industry.

“With Future Green Now, I’ll focus on creating solutions that help reduce energy consumption and environmental impact, working closely with customers to ensure their systems operate at maximum efficiency,” he said.

The CO2 refrigeration market is growing exponentially. Currently, there are more than 2,500 rack-type systems in operations in the U.S. and 67,000-plus running in Europe. Many major manufacturers are embarking on carbon-cutting endeavors, including Walmart, which recently announced its intention to eliminate fossil fuels by 2040 and intends to incorporate CO2 refrigeration into its stores. A number of other supermarkets and equipment manufacturers are full-steam ahead as well.

“Despite this immense growth, there isn’t enough urgency from the industry as a whole to learn CO2,” said Wetzel. “We’ll never keep up at our current pace. We can’t be afraid of change and must continue equipping ourselves with the tools and knowledge necessary to succeed.”

Wetzel continues to pour his heart and soul into the industry, delivering classroom lectures, recording countless podcast episodes, and leaving his fingerprints on as many compressors as possible. Undoubtedly, he’s leaving an immense impact on the ever-changing HVAC refrigeration industry.

“This industry is evolving rapidly, and I’m proud to contribute to its growth and innovation,” said Wetzel. “Let’s continue working together to push the limits and shape a greener, more sustainable future.”