“Better design can make considerable improvements in both efficiency of operation and comfort.”

Tishler’s comments are directed toward forced-air heating and cooling systems, using a common distribution system for the convenience of central filtering, humidifying, and the efficient introduction of fresh air.

Conventional systems are strictly on/off, supplying full capacity or remaining inactive. Thermal losses determine the rate of temperature change between cycles when the thermostat is off.

“An optimal system would control the rate of temperature change for both temperature increase and decrease when in either the heating or cooling mode,” he related. “The system would be controlled continuously when the thermostat is both in the on and off conditions, compensating for the actual losses and operating more efficiently.

“More moisture would be removed from the air during cooling, resulting in comfort at a higher thermostat setting. Continuous control would eliminate the cold blast when the system is activated as well as any uncomfortable conditions between cycles.

“In addition, the large pulse of heat would be eliminated in the heating mode when the thermostat turns on.”

With this optimal system, the air velocity would remain constant and the temperature of the air regulated. The system would have a high-volume, low-velocity air supply providing air circulation simulating a comfortable breeze.

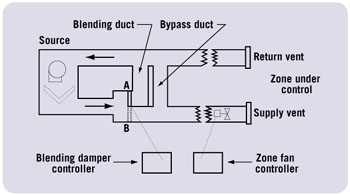

The configuration of such a system is shown in Figure 1. Although only one zone is shown, others would be identical and connected to the source in parallel. The zone fan is controlled separately to provide constant air pressure in the supply duct. This produces constant air velocity in the zone at all times.

The system functions continuously, increasing or decreasing temperature in all zones. When the blending damper is in position A, the unblended air supply of the source is fed to the zone. If the air supply exceeds that required by the zone fan to maintain constant supply duct pressure, much of the excess will be returned to the source by the bypass duct. This is a shorter path and offers less resistance than the path through the zone under control.

The blending damper controller monitors the temperature in the zone and adjusts the blending damper to produce a controlled rate of temperature change. Some of the supply air will be bypassed through the blending duct, causing the air supply to be less than that required by the zone fan. The additional amount is drawn through the path of the return duct in the zone and the bypass duct blending the source air with the cooler return air.

When the damper is in position B, the source is bypassed completely through the blending duct and the air supplied to the area under control is entirely the air that passes through the return vent.

“There are many more applications for a controller which could monitor and control the rate of temperature change in an area,” stated Tishler. “The output of the source or the speed of the source fan could be controlled to account for zone changes and thermal losses.”

In hydronic systems, cooler return water could be blended with supply water similar to the forced-air example.

The Lorlin Controller is a recently patented device which controls the rate of temperature change and has been designed for these applications. The controller can also improve supplementary heat requirements in heat pump installations. For air-source heat pumps, as the outside temperature drops below freezing, the output of the pump is insufficient and is usually supplemented with less efficient resistance heating elements in the supply duct.

“The controller monitors the temperature of the air in the return duct when a thermostat calls for heat,” said Tishler. “The power supplied to the resistance heating element is adjusted to produce a managed rate of temperature increase whenever that rate is below the design limit.”

The system operates independently of outside weather conditions and automatically takes into consideration all internal variables.

“The introduction of a product which controls the rate of temperature change has created many design opportunities,” he said. “I’ve suggested some applications, but all of the possibilities for this type of controller have yet to be investigated.”

For more information, Tishler can be reached at lorlin1@msn.com (e-mail).