The procedures for DSI flame rectification are pretty much the same for all manufacturers. It is a good idea, however, to check the specification sheets for the particular manufacturer’s equipment you are working on.

One of the primary uses for DSI systems has been on some power gas conversion burners. The initial problems with DSI systems have been eliminated by today’s technology — such things as multiple-try systems and what is called “soft lockout” (where the system will attempt several tries at ignition and, if it fails to ignite the burner, the system will shut down for 60 minutes, then go through another series of tries). This has prompted a comeback of DSI use with some manufacturers.

DSI Components And Specs

Standard DSI systems include the following components:

DSI Control Modules

Honeywell DSI control modules include the S825A, B, C, and D; the S87A, B, C, and D; and the S89A. All modules are for low-voltage (24 VAC nominal) application on gas-fired furnaces.When powered by a suitable 24-VAC, 60-Hz transformer and activated by the system’s temperature controller, they perform the following functions:

1. Check for a false flame condition (short to ground) before each startup. If a false flame condition is present, the module does not allow startup.

2. Generate a potential of 30,000 V (open circuit) at the spark igniter for direct ignition of the main burner.

Note: The S89A does not include a spark generator circuit. The S89A has an internal relay for activating a separate spark generator for ignition of the main burner.

3. Open the main valve(s) of the gas control(s) to allow gas to flow to the main burner.

4. Sense the presence of a main burner flame and discontinue ignition spark. If the burner fails to ignite within the trial-for-ignition period, the module goes into safety lockout.

5. If there is a loss of power, the systems will shut down safely. Startup is initiated when power is restored.

6. If there is a loss of the main burner flame, the trial for ignition is repeated. Safety shutdown occurs if the flame is not re-established within the trial-for-ignition period.

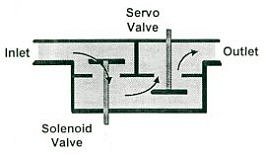

Gas Controls For DSI

The American National Standards Institute (ANSI) requires that all new DSI-equipped gas-fired appliances must have dual gas controls for positive shutoff of the main burner gas. This requirement can be met by using any of the following methods:Note: For direct burner ignition, there is no pilot; leave the plug in the pilot outlet.

Ignition, Flame-Sensing Hardware

Ignition and flame-sensing hardware for DSI systems is available in several configurations:Generally speaking, the separate flame sensors and spark igniters are used together, or the single electrode igniter-sensor is used alone. However, some appliances use a different combination of these components; for example, an igniter-sensor for ignition and a separate flame sensor and spark igniter for flame sensing.

Whatever the combination, the system must have components, or a combination of components, for spark ignition and flame sensing.

Check Safety Lockout

1. With the system power off and the temperature controller set to call for heat, manually shut off the gas supply cock.2. Turn the power on to energize the control module; begin spark ignition; immediately start timing.

3. Determine the number of seconds to safety lockout (spark cutoff). It should not exceed the time specified by the manufacturer.

4. After spark cutoff, manually reopen the gas supply cock. No gas should flow to the main burner.

5. Reset the system control module as described here:

Final System Checkout

Start the system and observe operation through at least one complete cycle to make certain all controls are operating safely, according to the manufacturer’s specifications.McElwain is the owner of Gas Appliance Service Training and Consulting, Riverside, R.I., which offers servicing and troubleshooting training for gas heat servicers. He may be reached at 401-437-0557.

Publication date: 01/27/2003