Owned by Wyndham Hotels and part of the Boulders resort complex located here, the Golden Door Spa opened on October 1, 2001, following 10 months of construction. Although CSST was not originally specified for this project, the material ultimately played a valuable role in reducing installation time and overall costs.

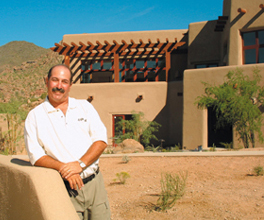

In this case, contractor Jeff Silverberg, of Phoenix-based JBS Plumbing Inc., estimates that flexible gas tubing (furnished by the Gastite Division of the Titeflex Corporation, based in Springfield, Mass.) saved his crew two full weeks of installation work, allowing his labor force to pursue other projects.

“The flexibility of CSST enabled us to maneuver the tubing through the available space at the Golden Spa in a lot less time and with a lot fewer problems than if we were cutting, welding, and threading metal pipe,” he said.

Twists And Turns

The project engineer initially designed the gas distribution system for the Golden Door Spa to use four-inch and five-inch black iron pipe. As with so many commercial projects, the gas lines must run above the ceilings throughout the facility. That meant the pipe had to be maneuvered around skylights, lighting-fixture connections, air conditioning ductwork, and assorted other obstructions in the attic. Twisting and turning the metal pipe through these spaces would necessarily entail huge amounts of time-consuming and expensive pipe fabrication, Silverberg quickly realized.“My machines cut up to two-inch pipe only, so I would have needed to find larger machines,” he explains. “Plus, I would’ve had to send the pipe out to another fabricator for special threading for the four-inch branches.”

Of course, the five-inch pipe must be welded, involving an additional hefty investment in manpower and equipment. So Silverberg approached local Gastite sales representative Earl Brockert of Southwest Sales Reps Arizona in Gilbert, Ariz., to help him recast the gas-distribution portion of the job. Together, they persuaded the engineer to switch his specification to CSST.

They also worked with the local utility, Black Mountain Gas, to boost the pressure into the building from roughly 2 psi to 5 psi, permitting a substantial downsizing of the diameter — and the cost — of the CSST. Instead of a single, five-inch metal line, as specified by the original plans, the project was fitted with three CSST lines, including a 1.5-inch run feeding a manifold in the boiler mechanical room and a 1.25-inch line feeding a second manifold in the pool heater room — both at 5 psi. The third line, 0.75-inch in diameter, delivers gas to the kitchen manifold at 2 psi, to accommodate the appliances there.

Collectively, the trio of lines supply gas to approximately 20 gas-fired appliances throughout the Golden Door Spa operation, including five decorative fireplaces, two boilers for hot-water heating, separate heaters for the spa and the swimming pool, several clothes dryers, and ranges, fryers, and other cooking equipment in the kitchen.

Safety Factor

All in all, the use of flexible gas tubing made the labor aspect of the project far more manageable and cost effective, says Silverberg. Instead of deploying four men to cut and weld metal pipe for three weeks, he needed only two working a single week with the CSST.“I’m a firm believer in Gastite and CSST because of the labor savings,” remarks Silverberg, who has also used the material on a 420-unit condominium project in nearby Scottsdale.

Here again, the project required the gas lines to run overhead in the ceilings, dodging and darting through various construction and mechanical obstacles.

“The labor could have been quite intensive there, too,” he says — if not for the use of flexible gas tubing.

But Silverberg points to another, equally important factor for using CSST on large, commercial and multifamily residential work: the peace of mind that derives from never having to worry about system leaks, which lead to costly callbacks and safety problems.

“If you use the proper accessories to protect the tube from nails and other potential puncture points, you should not have a problem,” says Silverberg, whose men received their installation certification training from Earl Brockert through local Gastite distributor Farnsworth Wholesale Supply.

“Between the two jobs, we have installed roughly 6,000 feet of Gastite product, and we’ve yet to experience our first leak or our first callback. That’s as big a cost-saver as any!”