However, from an airflow perspective, there is a complication: “What do you do with the ‘extra’ air?” This single question has confused contractors, produced unsatisfactory installations, and sometimes given zoning a bad name. Joe Ramunni of Arzel® Zoning Technology says, “The answer is to understand the dynamics of airflow and address the cfm issue proactively.”

Let’s look at how this problem comes up. Manufacturers design equipment with specific airflow criteria, typically 400 cfm/ton in cooling. Coils and heat exchangers are developed to optimize heat transfer at this rate. By convention, residential systems are laid out and equipment is chosen to maintain a static pressure of 0.1 in. wc. Dampering off parts of the ductwork will increase the static pressure and, therefore, increase air velocity and cfm delivery. This can create objectionable air noise and/or reduce the amount of air moving through the equipment.

Contractors have gone to great lengths to do as they were told and limit static pressure to 0.1 in. wc. Some have recommended oversizing ductwork to limit static pressure and eliminate the ‘extra’ air. This solution can cause overconditioning. Most zoning manufacturers currently recommend some kind of bypass arrangement. Passing the ‘extra’ air directly into the return works well, does not cause overconditioning, and is energy efficient — as long as the proportion of bypass to return air is not too large. Properly sizing the bypass duct for just the right amount of cfm bypass is where the confusion creeps in.

SIZING THE BYPASS IN 1990

The old theory of bypass sizing was “maintain 0.1 in. wc at all costs,” Ramunni says. At first blush, this seems to be the ideal. Residential ductwork is designed with 0.1 in. wc in mind. Equipment manufacturers choose fans to produce 0.1 in. wc of static pressure. So, sizing the bypass was as simple as taking your total cfm and subtracting the cfm of the smallest zone, then calculating bypass size at the normal velocity.Ramunni says, “The problem we have realized in using that sizing formula is that it sidesteps the dynamics of zoning and, in most cases, drastically oversizes the bypass.”

He goes on to say that an oversized bypass can greatly decrease the effectiveness of the system.

SIZING THE BYPASS IN 2002

“What most folks designing zoning systems don’t realize is that branch runs can deliver twice the standard design cfm without any appreciable air noise at the registers,” Ramunni says. “Just like a car is rated mpg from the factory, 100 cfm per 6-in. round duct is only a rating in a standard test or simulation. We can achieve mileage or cfm flows at higher or lower numbers as a result of trying to accomplish our objective. If we choose to get somewhere in a hurry, we achieve lower gas mileage; if we close off the duct feeding zones that have reached set point, we can push higher cfm levels into the higher load areas.“The other dynamic of zoning that is too often overlooked is that bypass ducts move air at 1,500 to 2,000 fpm when properly sized.”

He also notes that the dynamics of zoning allow increased static pressure to accomplish comfort objectives and help maintain proper heat transfer at the equipment. When properly sized, the bypass should return a minimal cfm to the equipment and send a maximum cfm to do the work at hand.

So, we are not limited to 0.1 in. wc, notes Ramunni. Static pressure is one of the variables that can be manipulated to serve customers’ needs. If there are underserved rooms far away from the equipment, or marginally sized ductwork, increasing the static pressure can push more air into those spaces. Increasing the static pressure also means that thermostats will be satisfied sooner, limiting run times and saving energy.

The equipment works more effectively and efficiently as well, asserts Ramunni, since a higher proportion of return air is ready to transfer Btu’s. He pointed to a case study to show how this works.

THE SMALL ZONE STUDY

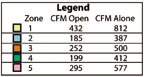

The Smith’s have a ranch-style home of approximately 2,000 sq ft. They experienced high solar gain in the south-facing sunroom. Mrs. Smith’s mother lived with them and required her suite be kept warmer than the rest of the family was comfortable with. This relatively modest home was divided into five zones. (See Figure 1.) The comfort consultant was concerned because some of the zones were less than 15% of the total cfm. The blower is a 3-ton unit that actually delivers 1,363 cfm. Table 1 shows the actual cfm delivered to each zone with all of the dampers open and then with each zone open by itself with a properly sized bypass in place. Notice that the ductwork could deliver almost twice as much air as normal.Let’s look at how the bypass was sized for our case study.

“The procedure is very straightforward,” says Ramunni. “To assure that we end up with the increased static needed to get the job done, we must look realistically at the dynamics of the system when a single zone is calling. When sizing bypass ducts for systems 5 ton and less, we use 300 cfm/ton as our base minimum. This takes into account the blower performance curve that indicates a drop in cfm output as the static increases.

“Keep in mind that the motor amps will actually drop when the cfm output decreases regardless of the static pressure. We then consider our maximum cfm delivery into the smallest zone with the static pressure elevated. As mentioned previously, we look for double design cfm (6 in. round at 200 cfm).

“We then subtract the ‘smallest zone cfm’ from our ‘base minimum of 300 cfm/ton’ to come up with our bypass cfm needs. Let’s look at our case study: 3 ton at a minimum cfm would be 3 x 300 = 900 cfm, with smallest zone calling. Smallest zone max cfm would be two 6-in. round branch runs at 200 cfm each equals 400 cfm total. So, considering the dynamics of zoning, we need to bypass 500 cfm to keep our static pressure and velocity within reason and yet allow as much heat transfer as possible at the coil.

“Another dynamic that plays into sizing our bypass duct properly is the bypass velocity. If we ignore this variable, we would grossly oversize our bypass. Most bypass ducts when properly sized will move air at velocities between 1,500 and 2,000 fpm.

“In our case study, we used 1,500 fpm to achieve our balance between maximum cfm to our smallest zone and minimum cfm back to the return. As you can see from our cfm results in Table 1, we accomplished our objective.”

Contractors who understand bypass sizing can manipulate static pressure in order to serve their customers’ comfort needs, says Ramunni. He advocates allowing the static pressure to increase and adjusting the bypass to just eliminate any objectionable air noise. “This will ensure a system that works well and gets the most out of every kilowatt of electricity or cubic yard of gas,” he says.

Publication date: 05/27/2002