In the last five years, there have been thousands of American projects ranging from mammoth applications such as the 350,000-square-foot David L. Lawrence Convention Center in Pittsburgh, down to more routine applications such as retail stores, churches, offices, gymnasiums, indoor swimming pools, warehouses, and industrial plants. Fabric duct is ideal for any application with exposed architectural ceilings. It's never used when ductwork is hidden in ceilings.

The main lure of fabric duct is the cost savings. Time and material differences between using fabric duct versus round spiral or rectangular metal duct can range anywhere from 10 to 60 percent depending on the diameter specified for the job. Simply put, fabric duct is hung from a suspension cable or anchored track system and installed similar to the way a shower curtain is installed. The time and labor savings can either be passed on to the owner or used to raise profit margins on design/build projects.

But there are more advantages to fabric duct than reduced time and labor. Other selling points are:

1. Lightweight - Fabric duct is approximately 90 percent lighter than its metal counterpart. This boils down to easier installation by smaller crews. It also could determine whether a project comes to fruition, especially in HVAC retrofit applications with roofs that wouldn?t be able to bear extra weight. In new construction, such as Star Precision's $6.2 million, 108,000-square-foot Longwood, Colo.-based metal fabrication factory, fabric duct's light weight saved the firm about $500,000 in labor, materials, and elimination of the need to put up a stronger supported metal building to accommodate hung metal ductwork.

3. Superior air distribution - It's no contest when comparing metal duct and registers to the linear diffusers of fabric duct. Metal duct registers located every five to 10 feet can't deliver the gentle and more evenly distributed airflow of linear diffusers that typically run the entire length of the duct. Diffusion can be custom-engineered at the factory to satisfy most throws and velocities. While a gentle air disbursement is preferred for occupied spaces, it's a critical factor in many applications such as sanding, painting, and coating areas. At Karges Furniture, Evansville, Ind., the gentle airflow of fabric duct's linear diffusers actually aids the varnishing and curing process of high-end handmade furniture. Metal duct would not have been feasible in this application.

4. Aesthetics - Fabric duct looks equally as aesthetic, if not better, as round spiral duct. At Rush Fitness Centers, Knoxville, Tenn., for example, fabric duct was chosen for its aesthetics at these high-tech health clubs and the benefits of even airflow and proper IAQ were added bonuses.

5. Maintenance - Metal duct can require painting while fabric duct is colored at the factory in standard or custom colors to match corporate colors or interior design motifs. Metal duct requires special duct cleaning equipment, whereas fabric duct can be disassembled, laundered at a dry cleaner or laundromat, and then reinstalled. At Dickinson College, Carlisle, Penn., fabric duct hanging above its indoor swimming pool would be difficult to paint periodically. The fact that the fabric duct was factory dyed to match school colors and even sport the Dickinson school logo, plus its non-corrosive features in humid and chemical environments, was part of the reason for choosing fabric.

6. Reduced labor - Fabric duct installations typically are installed with smaller crews and in 20 to 80 percent less man-hours than metal duct due to the ease of handling and simpler installation techniques. At Barney's Motorcycles, St. Petersburg, Fla., the air conditioning duct installation labor in the new showroom was reduced by weeks in this fast-track project because fabric was chosen over metal.There are many fabric duct types and most are offered by a variety of manufacturers. Typically, today's fabric duct is a blend of polyester fabrics. However, each model can vary by shape, function, price, color, and appearance, depending upon the application.

Duct Selection

By the time a fabric duct project reaches the installing contractor, the specifying, engineering, and selection of size, airflow, color, and shape has been determined by the architect or consulting engineer. The industry's top fabric duct manufacturers have representatives that either help with system design or act as liaisons with factory engineers who provide the technical engineering assistance.On design/build projects where a contractor is required to specify size and airflow characteristics, the manufacturer's representative is a vital part of the engineering team.

Incidentally, fabric duct is good for HVAC contractors that find themselves subcontracting the sheet metal portion of a design/build project. Instead of subcontracting, a contractor can install fabric duct with on-staff workers and make additional profits on a project.

Installation

Before installation, manufacturers can deliver the factory-engineered fabric duct to the jobsite or HVAC contractor's headquarters via UPS or other shippers. A large installation can involve dozens of lengths. Since all jobs are factory-engineered, all pieces arrive on-site numbered as to where and what sequence they should be installed.Sections can vary by length depending on the diameter of the duct. Smaller size lengths can range from 20 to 40 feet long, while larger diameters have shorter lengths for easier handling.

While putting up a 30-foot section of 40-inch-round spiral metal duct would necessitate a large installation crew to handle the weight and bulk, a similar length of fabric duct requires only two handlers because the fabric is approximately 90 percent lighter. On smaller projects, a contractor might save money by supplying only ladders instead of erecting scaffolding systems.

Tools to use for installation are no different than the tools needed for hanging metal duct: power drills, screwdrivers, pliers, and anchors for all types of building materials. Fabric duct needs no on-site cutting and typically is zippered together with factory-sewn industrial zippers. But don't throw away those tin snips. Metal plenums and metal duct (in enclosed ceilings) may still be needed to deliver the air from the air handler to the room(s) where fabric duct is applied. Remember, fabric duct is never concealed and is only suitable for open architectural ceilings.

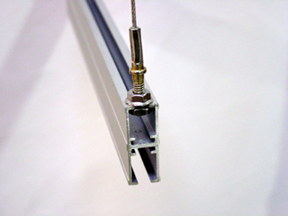

Support systems are similar among all major fabric duct manufacturers and they consist of either a cable system or an H-track system. The majority of projects that utilize fabric duct as their air distribution system consist of exposed steel truss roof structures (roof girder, purlin, rafter, beam). These support systems will be used in most cases for supporting the duct system.

Long cable runs will most likely need support(s) in the middle sections. This is accomplished no differently than supporting piping or other types of ductwork. Threaded rod anchored to ceiling joists is the most common hanging method. However, recent innovations have included the popular Gripple fitting that contractors use for hanging electrical conduit, lighting fixtures, piping, sheet metal duct, sprinkler systems, and other utility supplies that require leveling and on-site adjustments. The Gripple system is a faster method than C-clamps and threaded rod.

In this situation an installer takes a small length of aircraft cable and loops it over the bottom of the ceiling joist and under the fabric duct cable system. Both ends of the cable are easily strung through the fitting which can be tightened when the proper length is achieved (once it levels the sagging of the main fabric duct cable system run). The locking grip on the fitting can be easily reversed, thus freeing the cable for readjustment or disassembly.

Once the cable system has been suspended, hanging the fabric duct is no different than stringing a shower curtain onto a rod. The top of the duct comes with small clips that the cable is strung through. For larger diameters of 24 inches or more, a two-row cable system is recommended for aesthetics, but is not mandatory. With two cable systems holding the duct at 10 o'clock and 2 o'clock, potential sagging is eliminated and it enhances the aesthetics of the duct run.

A snap tab that's connected to the fabric has a hub as well that slides through the bottom of the H. Some manufacturers offer a locking nut for the top hub that prevents it from sliding in the H-track once it has been set in position. Like the cable system, a two-run H-track will eliminate possible sagging on larger diameter runs.

The H-track also comes in a surface-mount style for low-clearance situations.

Usually it takes only a few hours to become proficient at hanging either the cable or H-track systems. In addition, most major manufacturers offer factory consultation for installation.

Any HVAC contracting company looking to add another dimension to its services should look into fabric duct as an alternative to metal duct.

Cary Pinkalla is an industrial engineer and president of DuctSox, Dubuque, Iowa. For more information, contact the company at 866-382-8769, ext. 6055, or visit www.ductsox.com.

Publication date: 10/20/2003