In this fourth installment of the Btu Buddy series, the dispatcher calls Bob and asks him to catch a service call on his way home late in the afternoon. The homeowner is complaining of an overly hot house and says her air conditioning unit is running all the time.

Bob arrives at the home about 5:00 p.m. to discover that the temperature inside the house is 80 degree F while the outside temperature is 99 degrees F. This is the first really hot day in a region known for heat. Bob asks the owner what she knows about the way the system is performing. She tells Bob that the unit has run all day and doesn’t seem to be getting anywhere.

Bob goes to the back of the house and discovers the condensing unit is running — at least the fan is running. The compressor is not running, so he removes the compressor compartment door. The compressor is too hot to keep his hand on. Bob looks over the unit and quickly makes a decision that the condenser coil is extremely dirty and must be cleaned to operate correctly. While the compressor is cooling down, Bob prepares to clean the condenser with a water hose.

About this time, Btu Buddy appears and asks, “What procedure are you about to perform?” Bob says, “I am going to wash this condenser with water from the outside. That will save time.” Btu Buddy suggests, “Bob, if you only use water and wash from the outside inward, you are going to be making two mistakes. One, water alone will not clean a condenser and, two, you need to backwash the condenser in the opposite direction of the airflow for proper cleaning.”

“Why the opposite the direction of the airflow?” asks Bob. Btu Buddy explains, “The heaviest dirt will be where the air enters the coil. If you wash the coil in the direction of the airflow, you may drive the dirt deeper into the core of the coil, which has several rows. By backwashing, you push the dirt outward in the direction which it entered the coil.”

Cleaning The Coil

Bob gets a chemical detergent that is approved for cleaning a copper coil with aluminum fins, one that will not damage either metal. Btu Buddy tells Bob, “Some of the very harsh cleaners that people have used may deteriorate the connection between the aluminum fins and the copper tube in the coil. This connection is vital for good heat transfer.”Bob turns off the power to the unit. Btu Buddy reminds Bob, “You should lock the disconnect box and keep the key in your pocket. You may get a phone call and walk out to the truck for a moment and someone, a kid or someone else, may turn the disconnect back on. When you spray water on the unit, you may become an electrical circuit to ground. It should become a habit to always lock the disconnect box while working on the electrical system or cleaning the unit with water.”

Bob says, “It’s hard to remember all the correct steps for a service call.” Btu Buddy says, “When you realize that many of these steps are safety steps and can be life saving, you will remember. It seems that your memory is often in proportion to your responsibility. The more kids you have, the better your memory will become to safety details.”

Bob removes the top from the condensing unit and discovers that the wiring harness to the fan motor mounted in the top is long enough to lay the fan down beside the unit. The manufacturer did a good job on this. If the wiring harness were too short, the fan would have to be disconnected to move it to the side; then it would have to be reconnected later. Bob uses a sprayer, similar to a garden sprayer, to apply approved cleaning detergent to the condenser. He starts spraying from the inside, then goes to the outside, and saturates the coil with cleaner.

Btu Buddy says, “This coil is going to need to soak for about 15 minutes to let the detergent do its work. Why don’t you use this time to change the air filters and oil the indoor fan motor and the outdoor fan motor. The customer will get maximum value for your time, and believe me they will notice that, particularly if you tell them you have extra time and you are going to use it to their advantage. I believe you should always give added value and remind the customer. They will ask for you to be their service connection and be loyal to your company for the long term.”

The coil had soaked for about 20 minutes and Bob returned. He gave the coil another soaking of detergent and checked the compressor contactor while this was soaking in. Then he spread plastic over the control panel and fan motor to protect them from water spray. He took the water hose with a spray nozzle and began to spray through the coil from the inside out. Bob could not believe the trash that came out of the coil. It was full of grass clippings at the bottom.

“I wonder what this is all about?” asks Bob. Btu Buddy notes, “Look around and observe how the yard is cut. Look at the grass clippings on the side of the house up close to the condensing unit.” Bob then says, “It looks like the yard person is not using a grass catcher and is cutting the grass with the grass discharge aimed at the house, and when it goes by the unit, the grass clippings are hitting the unit. If the unit is running, it will suck them into the coil, particularly at the bottom.”

“Good observation,” says Btu Buddy. Bob goes and gets the homeowner’s wife and shows what is happening to her. About that time the husband comes home from work and Bob shows it to him. He says, “I cut the grass and never thought of what it is doing. From now on, I will either use a grass catcher or reverse the direction that I cut the grass to blow the clippings away from the unit.”

Determining If The Charge Is Correct

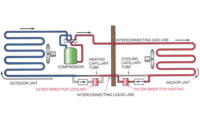

Bob puts the top of the unit back on and starts for the truck. Btu Buddy asks, “Where are you going Bob?” Bob says, “I am going for my gauges and ammeter to observe with when I start the system.” Btu Buddy says, “Just get your ammeter, I am going to show you a trick.” Bob returns with a clamp-on ammeter and clamps it on the common wire going to the compressor (Figure 1). Bob says, “The run load amperage is 23 amps.”Btu Buddy tells Bob, “The question is if the unit has enough refrigerant. If we put gauges on the system, we may alter the charge and it may already be charged correctly. So let’s try something else. If we put gauges on the unit, the gauges will not read anywhere near what you would expect them to read. The entering evaporator air is 85 degrees F and we have no idea what the humidity is. The increased humidity will add more load to the evaporator. We know that the indoor coil has a tremendous load on it. The condenser is going to have an extra load from the indoor coil, plus it is 99 degrees F, which is going to impose an even greater load on the system compressor. We know that when we arrived the compressor was hot. We believe it was overloaded because of the dirty condenser. Now here is what we are going to do. Put your hand on the suction line and get a good grip on it. Now when you reach over with the other hand and start the unit, tell me what you feel in the first few seconds of operation.” Bob starts the unit and in a few seconds, a puzzled look comes over his face. He tells Btu Buddy, “The suction line felt really cool for a few seconds, and then it began to warm. What is going on here?”

Btu Buddy explains, “With the system off, some of the liquid refrigerant is in the evaporator and some in the condenser. When you start the unit, if the charge is correct in the system, some of the liquid from the evaporator will move down the suction line and you will be able to feel it for a few seconds. If you walk over and turn the unit on and walk back to the unit, you may miss this event. This tells us that the unit most likely has enough refrigerant. Since gauge readings would be hard to interpret under the overloaded conditions, we will assume the charge is correct. This can be further proved by the compressor amperage. What is the amperage running?”

Bob looks at the ammeter and it is showing 23 amps. Since the compressor is fully loaded, this indicates the compressor is working and it is very likely the charge is correct in the system. Btu Buddy says, “You need to explain to the owners that the conditions in the house will not return to normal until very late tonight or maybe even in the morning. The unit will have to lower the humidity before the temperature in the house begins to drop. They will notice an abnormal amount of water coming out of the condensate drain during this time.”

Bob explains this to the homeowners and packs up to leave. Btu Buddy adds one more thought, “Bob, you have given the customer extra service and really paid attention to their needs. I suspect you will be on their list of people that they want to do their work from now on.” Bob tells Btu Buddy, “It takes a lot of concentration and knowledge to become efficient in this business. I wish everybody had a Btu Buddy to consult with.”

Bill Johnson has been active in the HVACR industry since the 1950s. He graduated in gas fuel technology and refrigeration from the Southern Technical Institute, a branch of Georgia Tech (now known as Southern Polytechnic Institute). He taught HVAC classes at Coosa Valley Vocational & Technical Institute for four years. He moved on to become service manager for Layne Trane, Charlotte, N.C. He taught for 15 years at Central Piedmont Community College, part of this time as program director. He had his own business for five years doing installation and service work. Now retired, he is the author of Practical Heating Technology and Practical Cooling Technology, and continues as a co-author of Refrigeration & Air Conditioning Technology, 5th Edition, all published by Delmar Publishers. For more information, he can be reached at 704-553-0087, 704-643-3928 (fax), or bmj@myexcel.com.

Publication date: 07/28/2003