The float, fixed orifice, and bucket steam traps were developed in the early 1900s. They were large, heavy, and expensive, operating on the principle that steam is a gas and condensate is a liquid. These traps are still used today and have changed little from their original design.

Major changes in steam trap design started with the development of the thermostatic trap. These traps operate based on the fact that steam is hotter than condensate. They provide a lightweight, low cost, compact unit with high capacity and a wide pressure range.

This trap evolution continues today with the advanced performance features and energy-efficient operation of bimetallic thermostatic and thermodynamic steam traps. The selection of a trap for a given service must consider many factors that require the knowledge of trap manufacturers, researchers, and other power plant engineers. There are several key design features to look for when selecting the steam trap best suited for an application.

There should be rugged construction with low maintenance costs and no live steam loss under all operating conditions. In the event of failure, the trap should be open for least disruption of process operation. The trap should have a self-draining design to prevent damage from freezing during plant shutdown.

Other features should include reduced valve seat wear and reduced purchase and fitting cost by incorporating a strainer, check valve, and air venting capability into the design. Efficient control of the heating process through effective condensate discharge, and fast plant start up with continuous venting of air and CO2 should also be considered.

In the process of trying to simplify their choices in steam traps, many plant engineers are making the selection based only on the purchase price of the actual trap, not the overall cost. The cost of the steam trap will include the additional parts required for piping and the cost of wasted energy (steam loss) during its operating life. Traps that address these issues will reduce the overall cost of installation and maintenance.

The selection of a steam trap must consider plant conditions other than condensate loads. Conditions vary, but it is common for traps to be exposed to stresses of a chemical, thermal, and mechanical nature. Corrosion from the action of oxygen and CO2 in the condensate attacks the piping interior surfaces.

Erosion from blast effect in intermittently discharging traps can speed up corrosion in return lines. Thermal effects include damage from freezing in cold weather and wide ranges in temperature changes during trap operation. Contamination from solids can restrict the movement of mechanical linkages or block orifices and vent holes. Mechanical vibrations transmitted through the piping or slugs of water traveling down the pipeline at high speeds (waterhammer) can easily damage certain types of traps.

To help decide which type of trap is better at meeting these ideal performance goals, resisting harmful plant conditions, and resulting in an overall lower cost, consider the advantages and disadvantages of the most common traps available today.

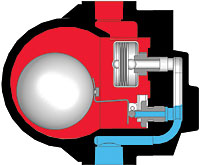

FLOAT AND THERMOSTATIC TYPE

The float and thermostatic (F&T) trap follows the condensate level in the chamber to open the discharge valve.A modulating action is produced by the increased opening due to the rising level in the chamber, but the hot and cold capacity are the same. Rapid response to changing load is possible, but as operating pressure increases, valve size must be reduced because the buoyancy force from the float is fixed.

The volume of condensate necessary to operate this trap is sensitive to freezing and the float can be damaged by waterhammer. This type trap is large and heavy and must be mounted in the horizontal position only. Main applications are process and space heating where condensate loads are light-to-medium at lower pressures. No strainer or check valve is required, but steam loss can result if internal air vents fail.

INVERTED BUCKET TYPE

In this type of valve, condensate flows around the bucket to discharge through the valve. The steam following this condensate fills the top of the bucket, which rises to close the valve due to its buoyancy.Steam escaping through a bleed hole in the bucket and condensing in the body causes loss of buoyancy allowing the bucket to fall and overcome the pressure valve. The action is cyclic with steam loss from the condensing action each cycle.

The volume of condensate necessary to operate this trap is sensitive to freezing and the bucket can be damaged by waterhammer. This type trap has some versions that are light and compact, but it must be mounted in the horizontal position only. Main applications are process, drip leg, and heating. Individual traps only handle a narrow range of pressures. No strainer or check valve is required, but a separate air vent or bypass may be necessary.

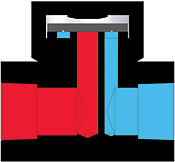

DISC TYPE

This type trap is compact and light, but horizontal mounting is preferred. As condensate is fully discharged on startup, steam enters the trap and the flow velocity under the disc rapidly increases. This reduces the pressure below the disc and pulls it down to close the trap. When the steam locked above the disc cools and condenses, it loses closing pressure and allows the cycle to repeat. The action is cyclic with some steam loss from each cycle.Main applications are small process, drip leg, and tracing. No check valve is required, but a strainer and a separate air vent may be necessary. High velocity air can be trapped above the disc, locking the trap in the closed position. The use of a bimetallic ring to hold up the disc during startup has been tried with limited success. Increase cycling can result when the trap is exposed to cold weather. Dirt can increase steam loss and disc wear, but freezing and waterhammer are no problem.

BELLOWS TYPE

This type trap is compact and light and can be mounted in any position. An alcohol/water mixture, sealed into a bellows, vaporizes as condensate approaches saturation temperature. The resulting expansion of the bellows closes the valve. Vaporization temperature increases as operating pressure compresses the bellows, in a rough approximation to the steam curve. This results in a cyclic action that modulates from a minimum opening on very light load conditions to full opening at maximum load.Main applications are small process, tracing radiators and general. No strainer or check valve is required. Freezing is no problem, but waterhammer can fracture bellows resulting in heavy losses of steam.

CAPSULE TYPE

Operation is the same as for bellows, but the alcohol/water mix is contained within a small, wafer-like element to reduce the motion and improve cycle life. The action is cyclic, with steam loss each cycle from the blast discharge. Dirt in this short travel valve can cause steam loss.

BIMETALLIC-THERMOSTATIC

This type trap is steam tight at set pressure only, blowing steam to low-pressure startup or reduced-pressure operation. A temperature sensitive bimetal stack closes the valve. This trap is individually adjusted to close at a fixed temperature, making it restricted to a narrow operating pressure range unless re-adjusted. The action is modulating, with good cold capacity and fair hot running capacity.A check valve and strainer may be necessary. This type trap is compact and can be mounted in any position. The main application is tracing. Freezing is no problem, but dirt and wear in the bimetal stack cause erratic response and changes in performance.

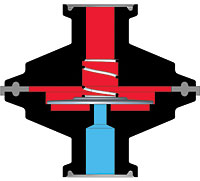

BIMETALLIC-THERMOSTATIC/THERMODYNAMIC

This type trap is compact and can be mounted in any position. A third generation design, the operation is the same as bimetallic-thermostatic, except a single delta-shaped element is used. This design provides additional thermodynamic flow forces, developed in the downstream expansion chamber, to improve the hot discharge capacity right up to saturation temperature.No strainer or check valve is required. The main applications are drip leg, process, heating, tracing and general. Freezing is no problem and the single piece, bimetallic stainless steel element is not affected by dirt or wear.

Thermostatic traps are often considered a universal steam trap, but no single type trap is ideal for all applications. Ignoring the variety of choices available to simplify your decision can increase the true cost of the steam trap. Steam trap manufacturers can give more detailed information on the operating characteristics and total cost of each type. It is important to remember that the price of a steam trap is the cost of installation, maintenance and wasted energy during its operating life.

Stephen P. Frank is a project engineer at Richards Industries Valve Group, Cincinnati. He can be reached at 513-793-2391.

Publication date: 03/27/2006