Bob gets a call from the dispatcher that a residential customer out in the country has an oil furnace that has to be reset to get it to run. Bob tells the dispatcher to call the customer back and tell them not to reset the furnace again until he gets there. He will be there in about an hour.

It is very cold so Bob gets there as soon as possible. When he arrives, the customer shows him where the furnace is located down in the basement. It is off because of safety again. Bob knows to check the furnace for excess oil before he resets the primary control. He uses his flashlight and examines the combustion chamber. The furnace is not hot, so he rolls up his sleeve and puts his hand into the combustion chamber and discovers that it is dry. He knows not to start up a furnace that has oil standing in the combustion chamber. His examination with the flashlight shows a lot of soot in the area of the combustion chamber and heat exchanger.

Bob shuts the furnace down and turns off the disconnect. He then goes to his truck for his oil burner service tools. He then removes the burner and sets it on the floor. The nozzle is changed with an exact replacement, using a nozzle wrench (Figure 1). He cleans the insulators with solvent and sets the electrodes with his electrode gauge. Bob then carefully removes the cad (cadmium sulfide) cell. About this time Btu Buddy appears and makes a suggestion, "Be careful not to touch the pins that plug the cell into the socket with your fingers. The current in that circuit is very low and any resistance, such as oil on your hands, may cause a problem."

Bob says, "I didn't realize that could be a critical point."

Btu Buddy responds, "Yes, that connection must be very clean. I notice the cad cell is dirty. What do you think caused that?"

Btu Buddy then says, "I think you are right. The fire was really bad. I hope that changing the nozzle will help. Was the filter behind the nozzle dirty?"

Bob answers, "It was really dark, like it had been filtering out something."

Bob then puts everything back together and is ready to fire the furnace. The furnace fires right up and Bob looks at the flame and comments, "The flame still doesn't look good. I wonder what is going on?"

Btu Buddy says, "I believe you should check the oil pressure. It may not be what it should be."

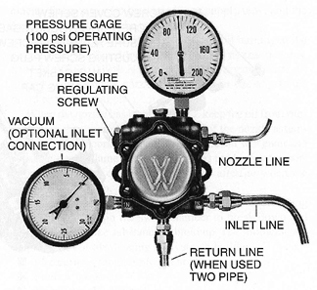

Bob installs gauges on the pump (Figure 2) and starts the furnace and comments, "The pressure on the pump inlet is below atmosphere and the outlet pressure is low."

Bob says, "I didn't think to do that. But I will do it now."

Bob turns off the oil at the tank and places a pan under the filter housing to catch any oil that may spill. He removes the filter cartridge and sees that it is really dirty with a lot of rust and scale in it. He changes the cartridge and refills the housing with fresh oil to prevent an air pocket from being in the line on startup.

While Bob is changing the filter, Btu Buddy says, "The tank is above ground and just outside the basement. The pump suction should not be in a vacuum because the oil level is above the burner."

Btu Buddy then says, "The inside of that tank must be getting rusty as scale is forming. I bet the owner has been tight with their money and not keeping the tank full during the summer. The tank will take in cool, moist air at night when it is cool, then it will expel part of that air the next day when it warms up. The best practice is to keep the tank as full as practical, particularly during the summer. Many owners let it run low and do not buy again until fall. That is not a good practice. You can change the filter and it may or may not get dirty again. The first season of burning may have removed enough of the dirt from the flowing oil."

Bob asks, "What do I tell the owner?"

Btu Buddy says, "The truth. Tell her that you may need to come back and change the filter again and tell her why. In fact it would be good to set up another filter change in about a week to inspect the filter."

Bob restarts the furnace. The gauges are then reading about 1 psi entering and 100 psi leaving the pump. Bob then says, "This looks good to me."

Bob removes his gauges and puts the furnace back in operation. He checks the air filter and finds it needs changing, so he changes it and oils the motors and is ready to leave when the owner comes down to the basement.

She says, "It is good to feel heat coming out of the system again. Thanks."

Bob explains the situation to her and she tells him that sure enough, they let the tank sit nearly empty all summer, but would follow his advice for next year. Bob sets up a time to come back and check the oil filter.

As they are driving away, Btu Buddy says, "Good job. That is another happy customer. One by one, your company is building a customer base that believes in you and has confidence in your abilities."

Bob says, "There sure is a lot to being a service technician."

Btu Buddy says, "There is even more to being a competent professional technician and you are doing it."

Bill Johnson has been active in the HVACR industry since the 1950s. He graduated in gas fuel technology and refrigeration from the Southern Technical Institute, a branch of Georgia Tech (now known as Southern Polytechnic Institute). He taught HVAC classes at Coosa Valley Vocational & Technical Institute for four years. He moved on to become service manager for Layne Trane, Charlotte, N.C. He taught for 15 years at Central Piedmont Community College, part of this time as program director. He had his own business for five years doing installation and service work. Now retired, he is the author of Practical Heating Technology and Practical Cooling Technology, and continues as a co-author of Refrigeration & Air Conditioning Technology, 5th Edition, all published by Delmar Publishers. For more information, he can be reached at 704-553-0087, 704-643-3928 (fax), or billj@carolina.rr.com.

Publication date: 01/23/2006