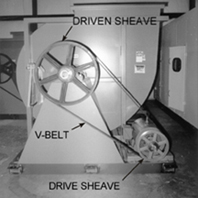

Fan terms vary in different parts of the country. The terms used in this article are defined as follows:

Drive sheave: The sheave on the motor.

Driven sheave: The sheave on the fan shaft.

V-belt: The belt that fits on the sheaves and transmits power from the motor to the fan. A small fan may have only one V-belt. Large fans have several V-belts.

MOVING PARTS

Safety rules on working with moving parts are just as important for fan safety.LOCK OUT

The only sure way to prevent a fan from starting unexpectedly is to lock it out:BLOCK OUT

A worker who was changing the V-belts on an exhaust fan de-energized the fan before starting work and locked out the switch. However, he did not block the blades of the fan. The suction in the ductwork turned the fan blades, and his hand was caught in the V-belt drive.This example shows the importance of blocking out a fan or any mechanical part that could start moving even with the power off.

V-BELT DRIVES

The advice given for all moving parts is especially important when working with fans. Never try to stop a V-belt drive with your hands. Let it stop completely before you touch it. A fan sheave may be coasting so slowly that it appears easy to stop. You cannot stop it. The combined momentum of the fan, motor, and drives is too strong. Your hands can be torn or crushed by being pulled into danger. Some sheaves may have protruding set screws. These will tear your hand even it there is only a slight rotation.Never - under any circumstances - put your fingers under V-belts. When working on a V-belt drive, even with the equipment locked out, it is easy to move the fan sheave slightly and have your fingers drawn in between the belts and the sheave. If the equipment somehow starts and your fingers are under the belts, you will probably lose your fingers.

BELT GUARDS

Fans must have guards (Figure 3) over the V-belt drive to prevent hands or clothes from being caught. You often have to remove a guard. Always replace the guard before starting the fan. If the guard must remain off while the machinery is running, put a barrier (such as a ladder) in front of it. This warns anyone that there is danger. The barrier also reminds you of the danger, because it is easy to forget the guard is off. The barrier is especially important in a fan plenum. This is usually a dimly lit place where it is not easy to see the exposed machinery.CHANGING THE V-BELT DRIVE

Often the technician has to change the fan output. In order to change the fan output in cfm (cubic feet per minute), the fan rpm (revolutions per minute) must be changed. The usual way to do this is to remove the V-belts and change the motor or fan sheave to one of a different diameter. This requires the following safety procedures:- You know how to calculate the new rpm that results from the change.

- You know the rpm limit of the fan. Speeds over the designed limit of the fan can damage the wheel.

- If there are no bolts in the bushing, use a wheel puller (Figure 4).

- If the sheave cannot be moved, apply penetrating oil and let it soak in for a while.

- If you must pound to move the sheave or bushing, do it as a last resort. Hold a piece of wood firmly against the hub and pound on the wood. Alternate from one side of the hub to the other. Be aware that the pounding force on any part but the hub will break or bend the sheave.

IN THE FAN PLENUM

Fan plenums are usually dimly lit and have very little extra room. In addition, they have moving parts such as V-belt drives. They require special safety precautions when working in them:Always open the fan plenum doors carefully. Excess pressure can blow the doors open violently on the fan discharge side.

You can be trapped in a fan plenum. If there is no shut-off switch in the plenum and the outside air and return air dampers close, the fan will create a negative pressure in the plenum. This pressure can easily be strong enough to prevent you from pushing open the plenum door.

Before working in a fan plenum, remove all debris and stored material. The plenum is sometimes a favorite place to store material. Anything stored in the plenum can contaminate the conditioned air. It also increases your chance of tripping.

Make sure you have all the tools you need before you enter the plenum. Once in an awkward position, it is so much trouble to get out and get the proper tool that you will be tempted to do foolish things such as using a knife for a screwdriver or using a crescent wrench for a hammer. These lead to injuries, damaged tools, and a poorly done job.

ELECTRICAL SAFETY IN THE FAN PLENUM

Review the Extra Edition article "Electrical Safety" by Leo A. Meyer (published 5/30/2005 in the Technical section). Follow all electrical safety rules carefully. In the fan plenum you are working in close quarters and can easily be grounded against metal. Codes require that the fan plenum must have a disconnect switch within sight of the fan motor.Avoid using extension cords in the fan plenum. Use battery-powered tools instead. If you must use cords, be very careful that they remain clear of any moving machinery.

Excerpted and reprinted from Safety for the Indoor Environment Technician by Leo A. Meyer, one of the books in the Indoor Environment Technician's Library series published by LAMA Books. For over 30 years, Meyer has been writing and publishing training materials for the HVAC industry. His books cover a wide range of topics, including heating and cooling, indoor air quality, sheet metal work, electricity basics, safety, and others. For more information, visit www.lamabooks.com.

Publication date: 07/24/2006