Formula 1. Click on the formula to view an enlarged version.

REFRIGERANT DENSITY

A refrigeration system’s pressures can dictate how much refrigerant will flow through the refrigeration system (flow rate). If the pressure of the suction line that delivers refrigerant gas to the compressor cylinders is high, the density of refrigerant vapors will be high and the mass flow rate of refrigerant will also be high.On the other hand, if the pressure of the suction line is low, the density of the refrigerant vapors will be lower and the refrigerant flow rate will be lower. Any time you fill a fixed volume (in this case the compressor cylinder) with a higher pressure, more refrigerant gas molecules will be present, causing a higher refrigerant density.

And remember from last month’s column, the mass flow rate of refrigerant through the compressor is a product of the piston displacement and the density of refrigerant filling the cylinder. The measurement of mass flow rate is expressed in pounds/minute. (See Formula 1.)

Formula 2. Click on the formula to view an enlarged version.

COMPRESSION RATIO

Both the high- and low-side system pressures can be expressed as a ratio called a compression ratio. Compression ratio is defined as the absolute discharge pressure divided by the absolute suction pressure. (See Formula 2.)Most service technicians realize that their service gauges read zero when not connected to a system, even though there is a pressure of approximately 15 psi on the gauges exerted from atmospheric pressure.

These gauges are calibrated to read zero at atmospheric pressure. Therefore, in order to use the true or absolute discharge and suction pressure at 0 gauge pressure or above, a technician must add 14.696 psi, or approximately 15 psi, to the gauge reading.

When referring to absolute pressure, psia (pounds per square inch absolute) is used to express the pressure’s magnitude. Psig (pounds per square inch gauge) expresses the pressure’s magnitude when referring to gauge pressure. Example 1 shows a compression ratio calculation for pressures above or equal to 0 gauge pressure.

A compression ratio of 8 to 1 (8:1) simply means that the discharge pressure is eight times the magnitude of the suction pressure.

Example 1. Click on the example to view an enlarged version.

DISCHARGE AND SUCTION STROKES

Now that we know how to calculate a compression ratio, let’s dig a bit deeper into what compression ratio physically means when applied to a cooling system. In reciprocating compressors, there has to be some ‘clearance space’ between the piston at top dead center and the valve plate, otherwise there would be a collision of the two.This intentionally designed clearance volume, or clearance pocket, traps a certain amount of refrigerant vapor after the discharge valve closes. Even though compressor manufacturers are reducing the amount of clearance volume found between the valve plate and piston head, some clearance will always remain. The clearance volume gas pressure is assumed to be at the discharge pressure if we ignore valve weight and valve spring forces.

The vapor left in the clearance volume has been compressed to the discharge pressure. Once the down stroke of the piston starts, this same clearance volume vapor must be re-expanded to just below the suction pressure before the suction valve can open, letting new vapors into the cylinder. The piston, however, will have already completed part of its suction stroke and the cylinder will already have been filled with re-expanded clearance vapors from the clearance volume before new vapors enter.

These re-expanded clearance volume vapors take up valuable space; suction vapors coming from the suction line cannot occupy the same space. Hence, suction vapors from the suction line will fill only the part of the cylinder volume that is not already filled with re-expanded discharge gases. Therefore, the total volume of the piston’s cylinder is not completely utilized by new refrigerant gases, and the system is said to have a volumetric efficiency.

VOLUMETRIC EFFICIENCY

Volumetric efficiency is expressed as a percentage from 0 to 100 percent, depending on the system in question. Volume efficiency is defined as the ratio of the actual volume of the refrigerant gas pumped by the compressor to the volume displaced by the compressor pistons.High volumetric efficiency means that more of the piston’s cylinder volume is being filled with new refrigerant from the suction line, and not with re-expanded clearance volume gases. The higher the volumetric efficiency, the greater the amount of new refrigerant that will be introduced into the cylinder with each down stroke of the piston; thus more refrigerant will be circulated with each revolution of the crankshaft.

The system will now have better capacity and higher efficiency. So, the lower the discharge pressure, the less re-expansion of discharge gases to suction pressure. Also, the higher the suction pressure, the less re-expansion of discharge gases because of the discharge gases experiencing less re-expansion to the higher suction pressure. The suction valve will open sooner.

A service technician can control, to a certain extent, how high and low the discharge and suction pressure will get. If the discharge (condensing) pressure can be kept low and the suction (evaporating) pressure can be kept as high as possible without affecting the refrigerated product temperature, the compression ratio will be low and the volumetric efficiency will be high. This will cause a higher mass flow rate of refrigerant to flow through the compressor and system.

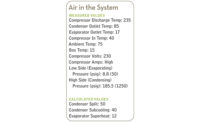

Sidebar: High and Low Pressure

Some of the causes for high head (condensing) pressures are:Some causes for low suction (evaporating) pressure are:

Publication date: 01/29/2007