Home » Duct Dynasty

Articles Tagged with ''Duct Dynasty''

Duct Dynasty: Estimate Room Airflow in Six Steps

Get your customers engaged by including them in the process

Read More

Four Ways You Might Be Using an Air Duct Calculator Incorrectly

For contractors, it’s better to light one candle than to curse the darkness

Read More

Measuring Filter Pressure Drop

It can be quite a challenging task, but these simple tips can alleviate some of the trouble

Read More

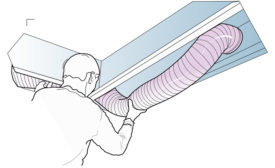

Are Your Installations Responsible for Lost Tons of Cooling?

Instead of selling the equipment’s efficiency rating, differentiate yourself by selling your craftsmanship

Read More

Copyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing